Inconel 601 is a standard engineering material with excellent heat and corrosion resistance. Inconel 601 also offers high strength and good processability, as well as excellent metallurgical stability and high resistance to carburization. Inconel 601 is hardened and strengthened through a cold working process.

Magellan Metals offers Inconel 601 in a variety of forms including:

bar

metallic line

sheet

plate

Forgings

Pipe fittings

flange

Seamless and welded pipes

Seamless and welded pipes

welding rod

| Chemical Analysis | |

| C | 0.1 max |

| MN | 1.0 max |

| S | 0.015 max |

| Si | 0.5 max |

| Cr | 21.0 -25.0 |

| Ni | 58.0- 63.0 min |

| Co | 1.0 |

| Al | 1.0- 1.7 |

| Fe | 6.0- 10.0 max |

Inconel 601 has many different industrial applications including:

radiant tube

generate electricity

chemical processing

catalyst support grid

aerospace

heat treatment

product

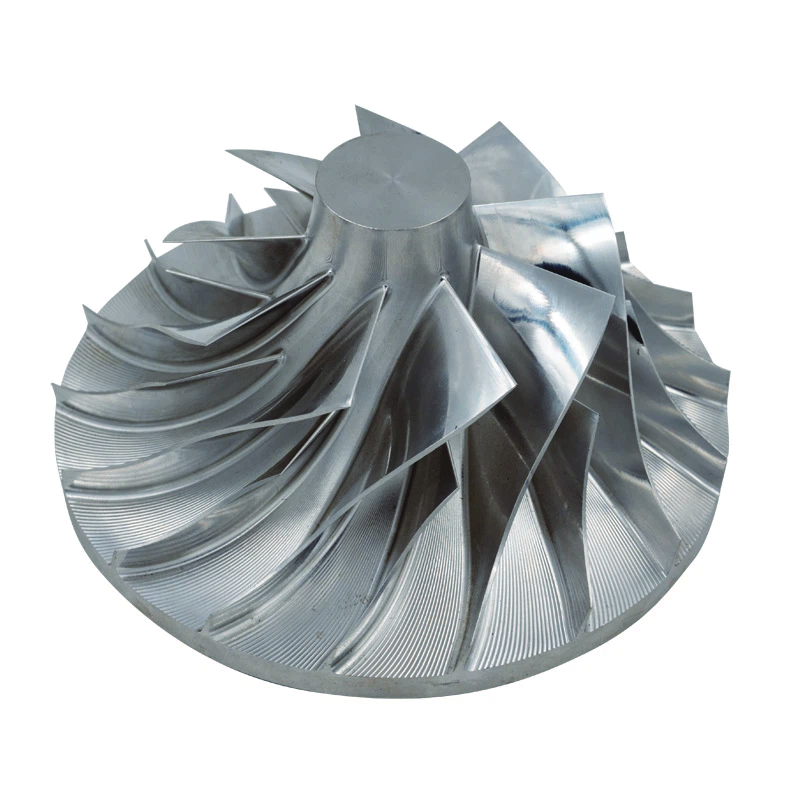

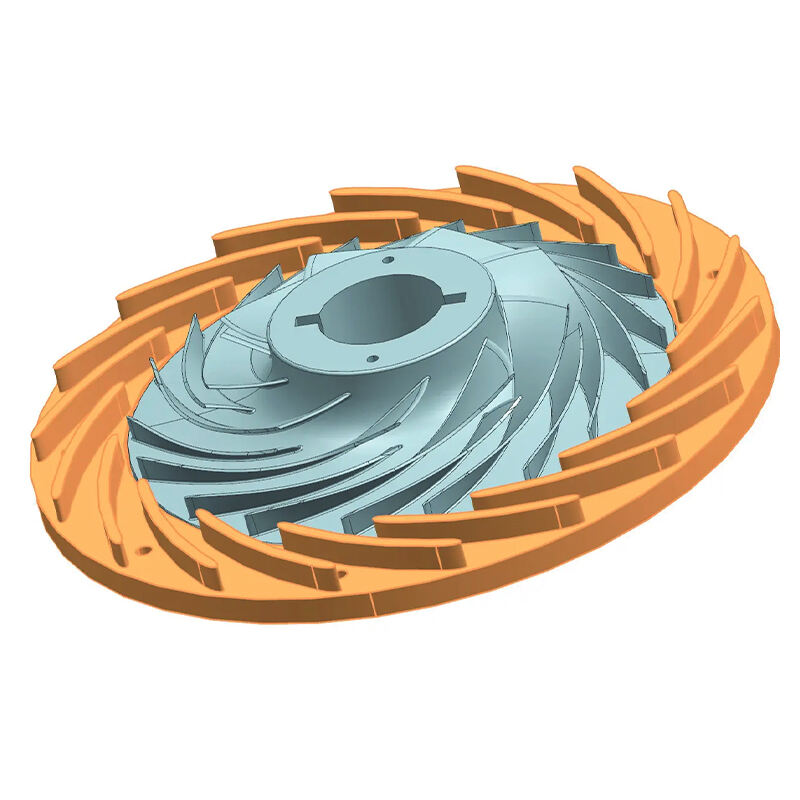

turbine wheel

turbine blade

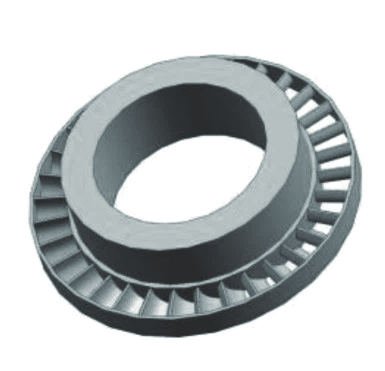

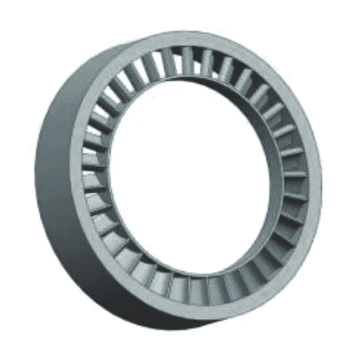

nozzle ring

compressor blade

guide vanes

diffuser

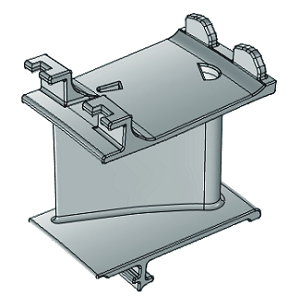

Segment

Turbine Rotor

Turbine Stator

Inconel sheet

Inconel pipe

Inconel rod

Inconel bolt and nut

Inconel Fasteners

Inconel wire

spring

According to drawings or samples

Inconel is a series of nickel-based high-temperature alloys known for its excellent high temperature resistance, corrosion resistance and oxidation resistance. Here are some key points about Inconel:

High Temperature Resistance:

Inconel retains its strength and integrity at high temperatures, making it ideal for use in high-temperature environments such as gas turbines, jet engines, and industrial heating applications.

Corrosion Resistance:

Inconel exhibits excellent corrosion resistance even in harsh environments such as seawater, acidic solutions and chemical processing plants. This corrosion resistance is due to the formation of a protective oxide layer on the surface of the material.

Strength and toughness:

Inconel has high strength and toughness, allowing it to withstand extreme mechanical stress and strain in demanding applications.

Versatility:

Inconel is highly versatile and can be processed into a variety of forms, including sheet, plate, rod, wire and tube, to suit different applications.

Alloying Elements:

Inconel typically contains nickel as the base metal, along with chromium, iron, and other elements such as molybdenum, cobalt, and niobium. These alloying elements give Inconel a unique combination of properties.

In summary, Inconel is a highly engineered material designed to operate in the most demanding environments where high temperatures, corrosion, and mechanical stress are prevalent. Their unique combination of properties makes them indispensable in critical applications across industries.

Aerospace field

Automobile and motorcycle manufacturing

Chemical industry

Marine engineering

Our professional sales team are waiting for your consultation.