Doeltreffende en koste-effektiewe verbrandingstegnologie

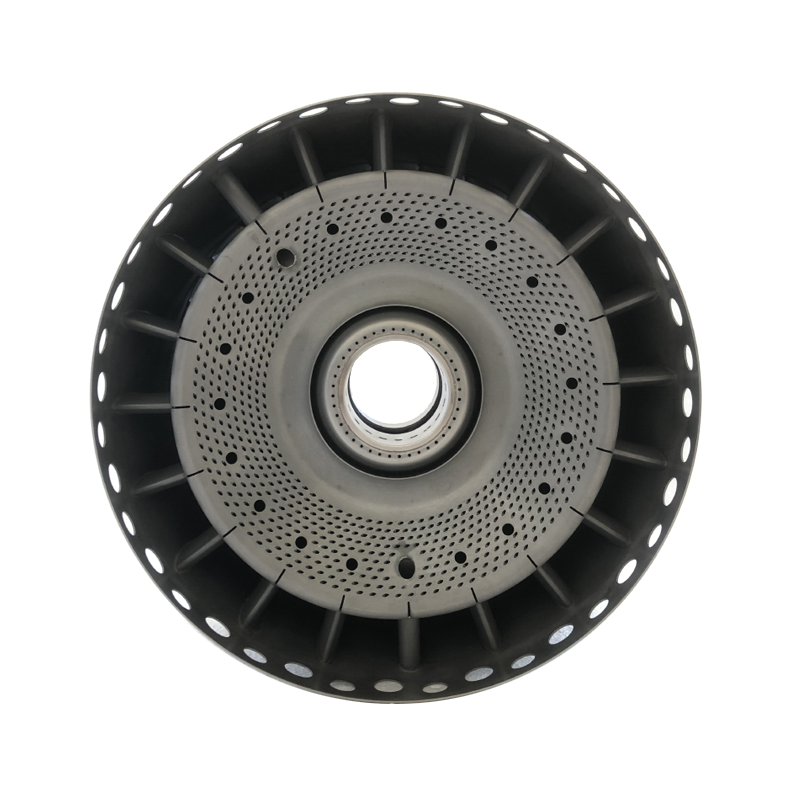

In industriële produksie is doeltreffendheid en kostebesparings baie belangrik. Ringvormige verbrandingskamers vir die O.B.T.-konsep. O.B.T se ringvormige verbrandingskamers bied top voorrang met 'n onoortreflike mededingende koste/prestasie-verhouding. Hierdie kavitasie-gebaseerde struktuur het 'n spesiale sirkelvormige ontwerp vir 'n meer volledige mengsel van verbrandingslug en brandstof, wat die beste toestande verseker. Hierdie innovasie minimaliseer brandstofverlies sodat, aan die einde van die dag, elke druppel tel. O.B.T se vermoë om die verbrandingsproses te optimaliseer, maak dit moontlik om mededingende pryse aan groot groothandelaars te verskaf. turbocharger turbine wiel

O.B.T. se annulêre verbrandingskamers het uitstekende hitteoordrag-eienskappe as een van hul sterke punte. Die rondheid laat ook toe dat hitte meer gelykmatig en doeltreffend deur die kamer versprei word, sodat niks morsword nie. Hierdie verbeterde hitteoordrag verhoog brandstofdoeltreffendheid, aangesien 'n groter persentasie van die brandstof se hitte-energie tydens die verbrandingsproses gebruik word. O.B.T. se 1.B.3-kamers lei gewoonlik tot beter brandstofdoeltreffendheid vir groothandelaars en minder energieverlies, wat op die lange duur verwarmingskoste bespaar. Turbo Kompressorpropeller (Aangepaste Deel – Tekenplan of Steekproef Vereis)

Daar was nog nooit 'n dag soos vandag waarop die belangrikheid van ons omgewing ernstiger opgeneem behoort te word nie. O.B.T. ringvormige verbrandingskamer waarin emissies en omgewingskwessies in ag geneem word. Minder giftige emissies: Die doeltreffende verbrandingsproses help om die vrystelling van giftige emissies in die atmosfeer te verminder. Deur emissies te verminder, bied O.B.T. 'n oplossing vir die omgewingskoste van industriële produksie. Hierdie produk gee groothandelaars die vertroue dat O.B.T. se kamers nie net hul besigheid maksimeer nie, maar ook sorg vir 'n beter toekoms vir die omgewing! Propeller Vir Sentrifugale Waaierventilator (Pasgemaakte Deel – Tekenplan of Steekproef Vereis)

Die enjin se prestasie en betroubaarheid is noodsaaklik in industriële produksie. O.B.T se ringvormige verbrandingskamer is ontwerp om beide hierdie aspekte te optimaliseer. Die relatief volledige verbranding produseer meer krag met dieselfde hoeveelheid brandstof. Verder waarborg die reputasie van O.B.T se kamers wat betroubaar is, probleemvrye en betroubare werking selfs in die harde omgewing van die industrie. Kliënte wat grootmaatbestekke van O.B.T se verbrandingskamers benodig, kan vertrou op voorspelbare prestasie en hoë betroubaarheid, terwyl dit die lewensduur van hul bedryf verleng. Lugkompressor Propeller (Pasgemaakte Deel – Tekenplan of Steekproef Vereis)

OBT se ringvormige kamers is die beste keuse vir groothandelaars wat op soek is na hoë-kwaliteit verbrandingsruimtes wat hoër doeltreffendheid, beter hitte-oordrag, minder emissies en beter prestasie bied. Ontwerp met doeltreffendheid en die omgewing in gedagte, bied O.B.T. se kamers 'n volledige oplossing vir industriële vervaardiging. OBT se verbrandingskamers is die doeltreffende, betroubare oplossing vir die kommersiële koper, of u behoeftes nou groot- of klein-skaalse produksie is. Kies vir O.B.T. vir hoë-rang verbrandingstegnologie wat spesiaal aangepas is om u industriële vervaardigingsbehoeftes te vervul en te oortref. Sentrifugale Geslote Kanaal Pomp Propeller (Volgens U Ontwerp – Tekenplan Vereis)

Ons verskaf 'n ringvormige verbrandingskamer, insluitend voorverkoopberading sowel as tegniese ondersteuning en naverkoopdiens om te verseker dat ons kliënte die mees aangename ervaring geniet. Ons gespesialiseerde span sal die behoeftes van kliënte evalueer en toepaslike produkte en oplossings aanbied. Wat tegniese ondersteuning betref, verskaf ons al die riglyne wat nodig is, vanaf die keuse van 'n produk tot installasie en inwerkingstelling, om te verseker dat kliënte ons produkte sonder moeite kan gebruik. Wat naverkoopdiens betref, het ons 'n foutlose dienstelsel ontwerp om vinnig op kliëntekomplimente sowel as -behoeftes te reageer, en om vinnige en doeltreffende oplossings te verskaf. Ons doel is om langtermynverhoudings te ontwikkel en kliëntevertroue en -tevredeheid deur uitstaande kliëntediens te verkry.

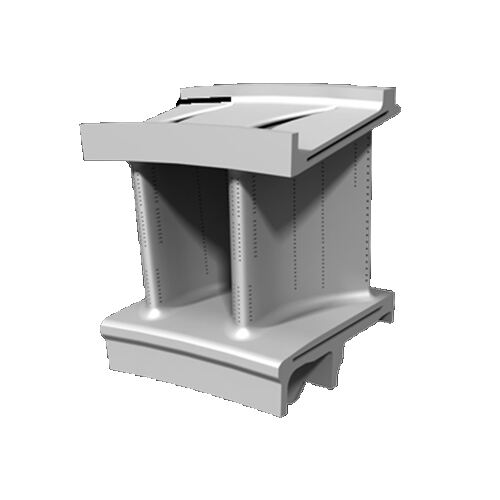

Ons kan turbineonderdele met hoë presisie en konsekwentheid vervaardig deur middel van 'n ringvormige verbrandingskamer, bewerkings- en smeeprosesse. Gietwerk stel ons in staat om onderdele met ingewikkelde ontwerpe, sterkte en duurzaamheid te skep. Smee gee onderdele 'n meer duursame en superieure meganiese eienskap. CNC-bewerkings-tegnologie verskaf, daarenteen, die hoogste presisie en akkuraatheid vir elke onderdeel, wat die kans op foute en die vervaardiging van substandaardprodukte verminder. Ons ervare tegniese span werk altyd aan tegnologiese innoverings en prosesverbeterings om te verseker dat ons produkte aan die voorpunt van nywerheidstegnologie bly. Ons is toegewy aan die bevrediging van ons kliënte se vereistes vir hoëprestasie-onderdele deur tegnologie voortdurend te verbeter.

Ons volg die ringvormige verbrandingskamer vir gehaltebeheer om die prestasie en betroubaarheid van elke komponent te verseker. Die hele vervaardigingsproses ondergaan gehaltebeheer, vanaf die aankoop van grondstowwe tot by die finale toetsing van die produk. Ons voer ook gereeld gehalteoudits en -verbeteringe uit om voortdurende verbetering van produkgehalte te verseker. Ons is vasbeslote om die vertroue van ons kliënte te wen en hul langtermynverhouding te handhaaf deur hoëgehawte produkte aan te bied.

Ons maatskappy verskaf ringvormige verbrandingskamers en kan turbinekomponente in baie verskillende hoë-temperatuurlegerings vervaardig volgens die vereistes van kliënte. Ongeag die grootte, vorm of prestasievereistes, is ons in staat om dit te bereik deur gebruik te maak van ons buigsame vervaardigingsprosesse sowel as ons gevorderde prosesse. Ons werk nou saam met ons kliënte om hul behoeftes en toepassingssituasies te verstaan en bied dan professionele ondersteuning en aanbevelings. Ons het 'n wye reeks verwerkingstegnieke en materiale om aan die unieke vereistes van verskillende sektore en toepassings te voldoen. Ons help ons kliënte om hul mededingendheid op die mark te verbeter deur aangepaste dienste aan te bied wat prestasie verbeter en koste verminder.