Ever wondered what makes your car's engine run? The killer part for this is called the combustion chamber. Well, it is one of the things that keeps your vehicle on the road and moving down the pavement in a fluidic way efficiently. In this installment, we will go more in depth on what combustion chambers actually are and how they work to keep your car moving.

How to turn them on when you start the car? The second important liquid, also special by definition because it literally feeds the car with that power itself is fuel -it mixes in conjunction with air inside said combustion chamber. This mixture is the heart of an engine, this is what makes it move. A tiny spark is generated with the help of a small gadget known as a Spark plug, at an accurate time. This spark ignites the fuel and air mixture creating a tiny explosion. This is utilized to push one of these pistons down. It maybe scary so much explosion but do not worry who else an explosion can be such useful.

This explosion creates energy that forces a component cum piston. You can think of the piston like a powerful arm that goes up and down into a cylinder. The crankshaft is the part that rotates as the piston travels. It's like the heart of your engine, working to take all that energy from making small explosions and turn it into motion. This process is ignited throughout, resulting in the engine working and offering power giving the necessary boost to make your car running forward.

The fuel injector is a machine that dispatches the sprayer into each of those droplets in the combustion area. That is a good because aid mix the fuel with air evenly. This is where the spark plug comes in. That is essentially what creates the spark that causes this fuel and air mixture to explode. Last are the valves, which function as gateways to let air in and out of a combustion chamber. These fittings make sure that ample air reaches the combustion chamber.

A well-maintained combustion chamber will lead to your vehicle running better than ever before and using fuel even more efficiently. In simplest terms, a decent combustion chamber will allow the perfect amount of fuel and air to come together for an extremely potent explosion. Means, the fuel and air in will burn fully so that more power for car you get and also better mileage.

Many brilliant engineers over the years have come up with new ideas and improvements to combustion chamber. A standout advancement, then and today, is the turbocharger. A turbocharger -- a device that forces more air into the combustion chamber. This results in fewer emissions, but also allows the car to produce even more power from its explosions as it can burn additional fuel. Besides this, the turboychargers improve fuel, economy due to making better use of petrol already in the exhaust pipe.

Variable valve timing is another interesting innovation. What this smart system does is make the valves open and close whenever needed according to how fast or slow the engine is spinning and also depending on current load. It effectively controls the flow of air supply to combustion chamber making victory smooth run.

Our customer support is engine combustion chamber and includes technical assistance, pre-sales advice and after-sales assistance to ensure our customers have the best possible experience. Our experienced team will review the needs of customers and offer the most effective solution and recommendations for the product. We provide technical support starting with the selection of products to installation and commissioning. This guarantees that our clients are able to enjoy our products without problems. We have a well-developed after-sales service that allows us to react quickly to customer requests and problems and provide quick and timely solutions. We strive to establish long-term relationships with our customers and earn their trust and respect by providing quality service.

Our company follows strict engine combustion chamber standards in order to ensure excellent performance and dependability of each component. Quality control is conducted throughout the entire production process beginning with the purchase of raw materials through the test of the finished product. To ensure that the quality of our products is continuously improved, we perform regular audits and improvements. We strive to earn the trust of our clients and their long-term partnership by providing products of high-quality.

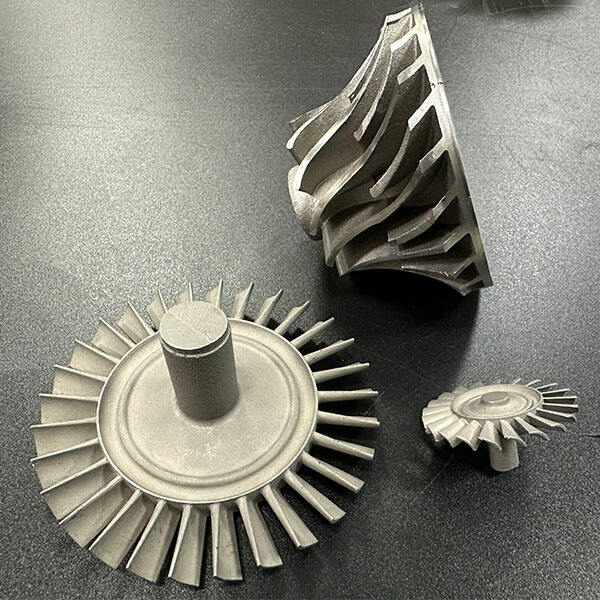

Our company is able to fabricate highly precise and stable turbine components through casting, forging and CNC machine processes. The casting process permits us to engine combustion chamber with complex shapes and high durability, while the forging process gives the parts better mechanical properties and longer lasting. CNC cutting-edge technology, on contrary, provides the highest precision and accuracy of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have an experienced technical team who continuously carry out technological innovation and process improvement to make sure that our products are always at the top of the industry in terms of technology. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continually.

Our company provides engine combustion chamber, and we is able to manufacture turbine parts from many high-temperature aluminum alloys in order to satisfy the demands of customers. Our flexible production flow and advanced technology for processing and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet any need. We work closely with customers to fully comprehend their requirements and applications scenarios and provide them with expert assistance and suggestions. We have a broad range of materials and processing capabilities to meet the special demands of various industries and applications. Our clients can improve their competitiveness on the market by offering customized services that optimize performance and reduce cost.