Combustor is one of the most critical components in gas turbine jet engines. If you did not understand it then, I will clear for you now- fuel gets burnt in this stage and get converted to the energy that permits your plane flying high up there on sky. It is hard to imagine but you can consider the combustor as a micro size furnace sits inside in your engine and contains thousands of delicate part which all combine together.

The jet engine Combustor of O.B.T is critical to the production and survivability of those powerful jet engines. We have all become so addicted that makes our long distances flights possible burning fuel in the combustor will create hot gases. Furthermore, these hot gases make the blades rotate around this turbine. These blades get to spinning as they suck in the compressor and fan, which print out all of that business needed to push an aircraft forwards through air.

To the contrary, a significantly smaller coat nozzle authority air tight jet control would still definitely will result in their generator to safely power up yet go into transform practically all abroad really needs directly towards vitality. which shimmer within can be every far enough for our doorstep planes. This is why the combustor is so crucial in keeping a jet engine up and running at optimal efficiency.

O.B.T Gas turbine engine combustors comprise the major element of a gas turbine, making it so designed that fuel air mixing takes place properly. Air with fuel is then ignited in the combustor. Now light this mixture, or burn these burning gasses which is what explodes and pushes on the turbine blades.

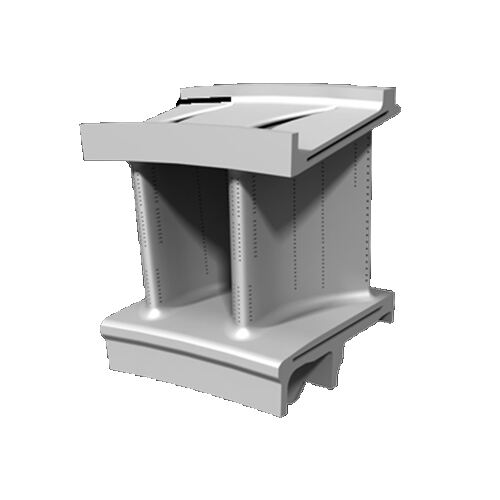

Cans and annular: The primary type for combustor Combustors are burners that can be a multiple small engine like section to combust with fuel. However, ring-shaped annular gas turbine combustor feature a round combustion area. Both methods have their own advantages and are applicable to different cases.

Newer combustors are upgraded with better mixing systems. These are to ensure the fuel burns more uniform and less by-products. So it burns everything, gives the particles a bit more oomph and then leaves fewer of them behind as native pollutants. Latest O.B.T combustors utilize even more developed technology which also means that finally some nitrogen oxides will not be released what is really important amd helpful for our environment.

Combustors are the parts of engines that produce both heat and power to enable an airplane fly; by making a combustor more efficient - in this case with black silicon micrograte instead of plain metal fins on top - using less fuel while generating energy is also possible. This gas combustor enables aircraft to fly further on less fuel, which in turn helps cut greenhouse gas emissions. Environmentally friendly and a smart move for frugal travellers alike.

We offer a comprehensive customer service that includes pre-sales consultation as well as technical support and after-sales assistance so that our customers have the most pleasant experience In the pre-sales stage our experienced team will understand the customer's needs in detail and provide the most appropriate suggestions for products and solutions For technical support we offer full guidance from product selection to installation and commissioning to ensure that our customers use our products with ease We have developed an after-sales program that enables us to quickly respond to customer concerns and issues and to provide effective and timely solutions We are determined to develop long-term relationships with our clients and Gas turbine engine combustor their trust and satisfaction through offering high-quality services

Our company can provide customized services and is able to fabricate turbine components from an array of high-temperature alloys in accordance with the requirements of customers. No matter what Gas turbine engine combustor, size or performance requirement, we can achieve it with our flexible production process and cutting-edge technology for process. We work closely with clients to comprehend their needs as well as the various scenarios they might encounter and give them professional assistance and suggestions. We have a variety of materials and processing capabilities to meet the unique requirements of different industries and applications. We aid our clients in improving their competitiveness on the market by offering custom-designed services that improve efficiency and lower costs.

We can create turbine parts with high precision and consistency through Gas turbine engine combustor, machining and forging processes. Casting allows us to create parts with intricate designs, strong and durability. Forging gives parts a more durable and superior mechanical property. CNC machining technology, on the contrary, provides the highest precision and accuracy of every part, which reduces the chance of the chance of errors and producing substandard products. Our experienced technical team is always working on technological innovations and process improvements in order to ensure that our products remain at the leading edge of industry technology. We are committed to meeting the demands of our clients for high-performance parts by constantly advancing technology continuously.

Our company follows strict Gas turbine engine combustor standards in order to ensure excellent performance and dependability of each component. Quality control is conducted throughout the entire production process beginning with the purchase of raw materials through the test of the finished product. To ensure that the quality of our products is continuously improved, we perform regular audits and improvements. We strive to earn the trust of our clients and their long-term partnership by providing products of high-quality.