About Inconel 725 Bolts:Except for that, there are unique bolts which is used in a tremendous pressure and stress position — inconel 725 bolts. These are produced from highly unique metal — Inconel 725. A combination of nickel, chromium and molybdenum make up this metallic substance. This particular mix makes it very-making use that is durable of 725 Bolts and great for the hard projects such as extra pulse.

Another high-strength bolt on the market is Inconel 725, living up to its five-digit number as bolts made from this material are especially helpful for jobs with lots of stress. These bolts take a lot of pressure before they snap apart. Therefore they are very dependable. And they are resistant so to rust and other types of corrosion making them the most durable shelf solutions in terms of your place. High wear resistance: In industries such as oil and gas where the going gets tough, excellent wear resistive al technology no matter what conditions you put it in.

Inconel 725 Bolts are composed of specific metal, namely Inconel; an alloy that is made mainly from Nickel with chromium and molybdenum as being the second most important constituents. Very few metals unity has some special properties that make it a great option against the hard work. It has some of the best qualities and resilience to rust so that it can last longer in harsh weather as well. Pros – Inconel 725 is also highly resilient against high pressure and very strong so it will not be prone to easily failing.

The best thing about Inconel 725 Bolts is that they are quite easy to install. They are available in a range of sizes, making it easy to locate your perfect match for any job. Even better, they install quickly and effortlessly to keep projects moving promptly. This is why you see these bolts used in multiple industries, from aerospace to oil and gas to even automotive; their use-case are vast.

Another advantage of Inconel 725 Bolts is that they are very suitable for the harsh environment owing to its high resistant against rust. Because the bolts are made in special metals, they prevent rusting and resist to other types of damages. For example, Inconel 725 bolts have a higher fatigue strength and can continue to perform well in such conditions.

Inconel 725 Bolts You should go on adding the Inconel 725 bolts in your home or works when there is a high pressure and an extreme temperatures. Because of their heat treating process, Traxda’s grade 8 bolts come out strong with rust resistance built in to last and work well for the long run. If you are in a field where severe states remain prevalent, say an oil and gas market building to grade Inconel 725 Bolts will definitely conserve from utilizing equipment to operate smooth.

The industry of Oil and gas is also recognized as one of the most challenging industries in all over globe The tools of the trad in this industry operate under temperatures, pressures and chemical conditions that outstrip all but a few other areas. Inconel 725 Bolts are the ideal fit due to their distinctive traits that matches this resistant industry. This makes them incredibly stout and corrosion resistant, ideal for oil & gas applications.

We adhere to the strictest guidelines for quality control to ensure the inconel 725 bolts and reliability each component. Every step of the production process is monitored for quality starting from the purchase of raw materials all the way to the final test of the product. To ensure that the quality of our products are continuously improved, we conduct regular audits and improvement. We want to win the trust of our customers and their long-term cooperation by providing high-quality products.

We offer a comprehensive customer service which includes pre-sales advice as well as technical support and after-sales support, in order to ensure our customers get the best experience. In the inconel 725 bolts the team's professional staff will understand the customer's needs in detail and provide the most appropriate suggestions for products and solutions. We provide technical support starting with the selection of products, through installing and commissioning. This guarantees that our clients are able to use our products without any problems. We have an established after-sales process that allows us to quickly respond to customer concerns and issues and to offer effective and prompt solutions. We want to create long-lasting relationships with our customers and gain their trust and satisfaction through offering high-quality services.

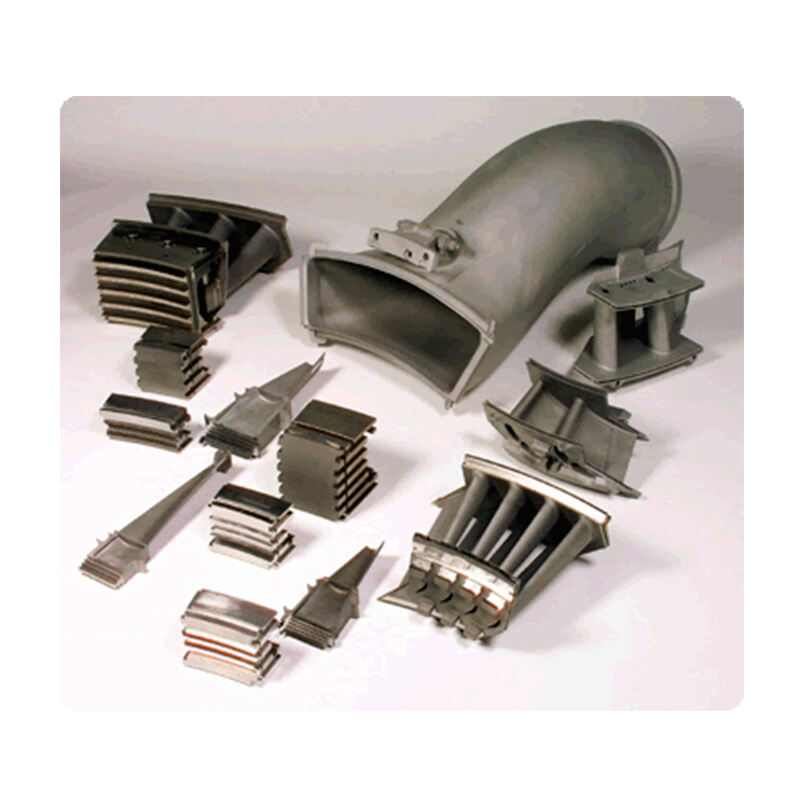

Our company can fabricate highly precise and stable turbine parts through casting forging, and CNC machining. Casting allows us to create components with complex forms, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC technology for machining, on other hand, ensures high precision and consistency of every part, which reduces the chance of the chance of errors and producing substandard products. Our technical team that constantly carries the latest technological advancements and process improvement to make sure that our products are always at the top of the industry in terms of inconel 725 bolts. We're determined to meet our customers' demands for high-performance turbine components through continuous technological advancement.

Our company offers customized services and is able to fabricate turbine components from many different high temperature alloys based on customer specifications. Our flexible production flow along with our advanced process technology and our capability to meet inconel 725 bolts, such as size and shape, as well as performance can allow us to meet any requirement. We work closely with clients to comprehend their needs and the potential scenarios for their applications, and then give them professional guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements for applications allow us to fulfill the particular requirements of various industries and application. With our customized services, we help our customers optimize efficiency and costs of their products, and improve market competitiveness.