The components of an airplane are extremely valuable as they come together during the flight process. Yet again, one of the most critical components in an aircraft is its jet engine. You can understand a jet engine as being just like big fan blowing really fast air, which makes the aircraft go at incredible speeds in here. There is what is called a turbine inside the jet engine. It has blades which are special parts in it. Those blades spin so fast, and they help the airplane go faster too! But the blades need to be very robust as they spin so fast and that generates huge amounts of force.

Originally used on jet-engine aircraft, the turbines were constructed of metal blades that could resist a variety of motor hazards. Metal is strong and can move plenty of air, but it heats up very quickly when spinning at the high speeds required for decent cooling. The moment the metal melts, there you have a blade that can no longer function. This is a big problem! This in turn led engineers -the people who design and build things- to try figure out other materials that could survive the high-temperature, intense conditions found inside a jet engine.

Ceramic is a type of material which can withstand heat. Ceramics are hard, making them strongHigh melting point That said, ceramics have a crippling flaw: If they are not produced perfectly, they tend to be very brittle. So the engineer had to come up with a way of making ceramics even stronger so they could use it in jet engines without worrying about them failing due to tensile strength.

Some time ceramics are made stronger by stirring in a little metal. These miniscule pieces helps bond the ceramic material together so that it does not break. Engineers also can bake the ceramics in a special oven at very high pressures. This method is known as sintering, Sintering helps the ceramic to becomes much tougher and harder... This is actually very important, because once they become a blade that needs to spin with extreme speeds all around inside an engine.

The third common material for jet engine blades is a metal alloy. Metal Alloy - a metal alloy in simplest terms is just plain old metals mixed together with one another. Metal alloys have high strength and are not melt at very temperature. They are also shapeable for transformative reasons, making them ideal to create turbine blades that size and fit perfectly into the jet engine.

It's been more recently that engineers have started to develop a new type of material for turbine blades last known as ceramic matrix composites. the new material is a ceramic-metal alloy that the road straightening pressWe hope this excites you because it sure did us --This hot-off-the-forge stuffIt combines select characteristics from both ceramics and metal alloys. The result is a very high strength / durability, low weight material. This is super important because the lighter a turbine blade, more weight less jet engine has to pull around. This makes the airplane able to fly faster and use less fuel!

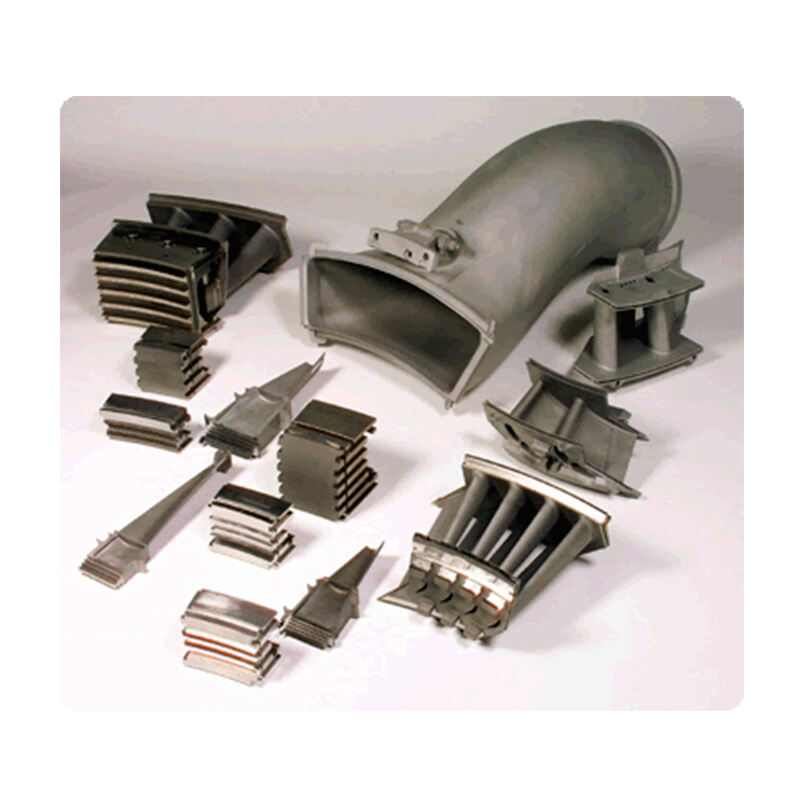

Our company is able produce highly accurate and consistent turbine parts by casting, forging, and CNC machining processes. The casting process allows us to produce parts with intricate shapes and strong durability, while the forging process gives the parts better jet engine turbine blade material and longer lasting. CNC machining technology, on the contrary, guarantees consistent and high-quality of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have a highly skilled technical team that constantly carries out technological innovations and process improvement to make sure that our products stay in the forefront of industry in terms of technological. We are committed to meeting the requirements of our customers for components that are high-performance by developing technology continually.

Our company provides jet engine turbine blade material, and we is able to manufacture turbine parts from many high-temperature aluminum alloys in order to satisfy the demands of customers. Our flexible production flow and advanced technology for processing and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet any need. We work closely with customers to fully comprehend their requirements and applications scenarios and provide them with expert assistance and suggestions. We have a broad range of materials and processing capabilities to meet the special demands of various industries and applications. Our clients can improve their competitiveness on the market by offering customized services that optimize performance and reduce cost.

Our comprehensive customer service includes pre-sales consulting technical support and after-sales services to ensure that customers enjoy the most enjoyable experience Our expert team will assess the needs of customers and offer appropriate product suggestions and solutions We provide technical support starting with the selection of products through installation and commissioning This ensures that our customers are able to enjoy our products without issues For after-sales support we have developed an efficient service system that can respond swiftly to customer issues as well as needs and provide jet engine turbine blade material and efficient solutions Our goal is to create long-term relationships and gain customers trust and their satisfaction by providing superior customer service

We adhere to the strictest guidelines for quality control to ensure the jet engine turbine blade material and reliability each component. Every step of the production process is monitored for quality starting from the purchase of raw materials all the way to the final test of the product. To ensure that the quality of our products are continuously improved, we conduct regular audits and improvement. We want to win the trust of our customers and their long-term cooperation by providing high-quality products.