Low-pressure turbine blades are one of the most important parts in machines that generate electricity. These blades are part of what transforms the heat energy into kinetic motion which powers a generator that we use to get electricity for our home, schools and businesses. Let us delve into this topic of low-pressure turbine blades in more detail in the accompanying text. In the process we will know everything about how they are created, what materials do these things need to make (rubber bands? ball bearings?), how should one use them efficiently, protect um... care for then properly and why when it doesn't work as expected.

There are differences in design of low- and high-pressure turbine blades They are way bigger and their shape is curious to say the least. This special shape matters because It serves in a high efficient energy extraction from steam. Steam moves through the blades and as it does that, steam pushes on these veins and they kind of spin around reducing in a generator. Each company may develop differently shaped and sized blades, they each have the same objective: aiding to make the machine perform optimally in producing as much electricity or potential energy. This design is important, because this information can help us why/how these fans efficiently make energy production work.

Low-pressure turbine blades are very carefully selected: the choice of materials is not easy. These blades must be built very durable, because they have to endure high temperatures and pressures all while getting forced through steam. The blades are exposed to temperatures upwards of 1000 degrees and steam, so they can be easily broken if proper materials arent utilized. Consequently, the low-pressure turbine blades are subjected to high temperatures and large pressure gradients which is why materials for Low Pressure Turbine Blades should be strong enough that can perform under such harsh circumstances. These blades are mainly made from special metal mixtures such as nickel-based alloys and titanium based alloys, though some contain ceramics. These can continue to function in harsh environments, preserving overall strength and toughness of the blades.

The low-pressure turbine blades are designed to extract more useable energy from the machines. A sharp edge on these blades extracts more energy from the steam, which means they can generate directly into additional electricity. The blades must be precisely engineered for the heat, temperature and pressure requirements of a specific machine in order to work as desired. There are other things that matter a lot, too - how smooth the blade is (better cooling), whether it cools decently at least some of the time and can seal pretty well. This in turn allows machines to produce generating electricity without requiring a higher volume of fuel from the blades doing so effectively. It also decreases the use of other types of energy while simultaneously promising a massive net savings over time.

This way you can be sure that your low-pressure turbine blades are in the best possible condition so they last longer and work as it should. Regular maintenance can reveal any issues, help prevent damage and ensure the blades work at their best. The following DeWalt table saw maintenance tips will help keep those blades nice and sharp without causing any hazardous accidents. Inspect The Blades Regularly A good maintenance regime begins with checking the condition of your blade on a frequent basis; that way, you can spot for signs of damage or wear before they spiral out to more serious issues. Cleaning the blades is also important to take out anything dirty, rusty and everything that makes them not as good in terms of performance. Third, should there be any blades that are in bad shape, it is very important to repair them or replace the new ones for maintaining machine workability. Properly maintenance also extend the life of machinery and keep it running in peak condition.

In some cases the low-pressure turbine blades get disturbed and this causes the machine to breakdown, that eventually results in cessation of power production. The important point to note in this case is that, why do these failures happen? the reason for such a question is not only identification of actual problem causing factors but also so as corrective activities can be taken accordingly. There are several ways to investigate low pressure turbine blades( LPT)problems. At this stage, the blades are visually inspected to determine if there is any visible damage or general deformation. Second, cutting out samples of the material that comprises the blades and examining it can give clues as to why they failed. The bed of the blades running tests and setting models can enable us to understand how design, materials, and operating conditions make contributions with respect to failures.

Our company adheres to strict quality control guidelines to ensure excellent performance and low pressure turbine blade of every component. Quality control is carried out throughout the entire process of production beginning with the purchase of raw materials to the test of the finished product. We also regularly conduct quality audits and adjustments to ensure constant enhancement of the product's quality. Our goal is to win the trust and cooperation of our customers by providing high-quality products and to become an industry leader.

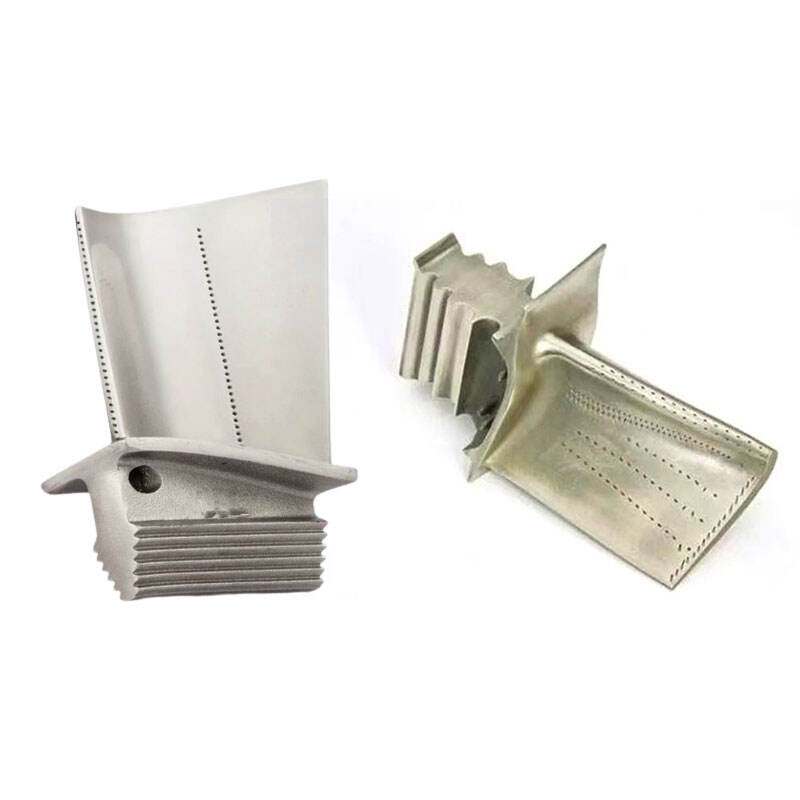

We are able to create turbine components with high accuracy and consistent quality through CNC machining, casting and forging processes. Casting allows us to create parts with complex shapes, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC low pressure turbine blade technology, on other hand, ensures the highest precision and accuracy of each piece, minimizing mistakes and ensuring that the product is of a high standard. Our highly skilled technical team is continuously developing technological advancements and process optimizations in order to keep our products at the cutting-edge of technology in the industry. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continuously.

Our customer support is comprehensive and includeslow pressure turbine blade, technical support, and after-sales services to ensure that our customers get the best experience possible. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support starting with the selection of products to installation and commissioning. This ensures that our clients are able to use our products without any issues. We have a well-developed after-sales process that allows us to swiftly respond to issues and needs of customers, and to provide effective and prompt solutions. We are determined to develop long-term relationships with our clients and gain their trust and respect by offering high-quality services.

Our company offers custom-designed services and can make low pressure turbine blade in an array of high-temperature alloys in accordance with customer specifications. Whether it is a specific dimension, shape or requirements for performance, we can accomplish it by using our flexible production process and cutting-edge process technology. We collaborate closely with our customers to comprehend their needs as well as the various scenarios they might encounter and then offer them expert assistance and suggestions. Our diverse selection of materials processing capabilities, processing capabilities as well as specific requirements to the application allow us satisfy the specific needs of various industries and application. With customized services, we help our customers optimize the performance of their products and reduce costs, and improve market competitiveness.