A steam turbine is a powerful invention that creates electricity to power other technologies which are used on the daily basis. It converts the steam to energy, which can be employed to power machinery or produce electricity for our houses and schools. One important component of this machine is called a nozzle. Okay, here we will get to know why is the nozzle important and how they work to allow the steam turbine for its intended performance.

A nozzle is the small orifice in the steam turbine. In other words, this is the guy responsible for regulating the steam that enters the turbine. The flow of steam needs to be just as controlled in order to have the perfect recipe. The turbine might not generate enough power if the turbine nozzle does not have of steam to be sent through it. Conversely, if there is too much steam and the turbine cannot cope it would be like inflating a balloon beyond its point of burst. Hence, the extraction of the O.B.T nozzle should be very accurate to permit just enough steam in order for the turbine runs smoothly.

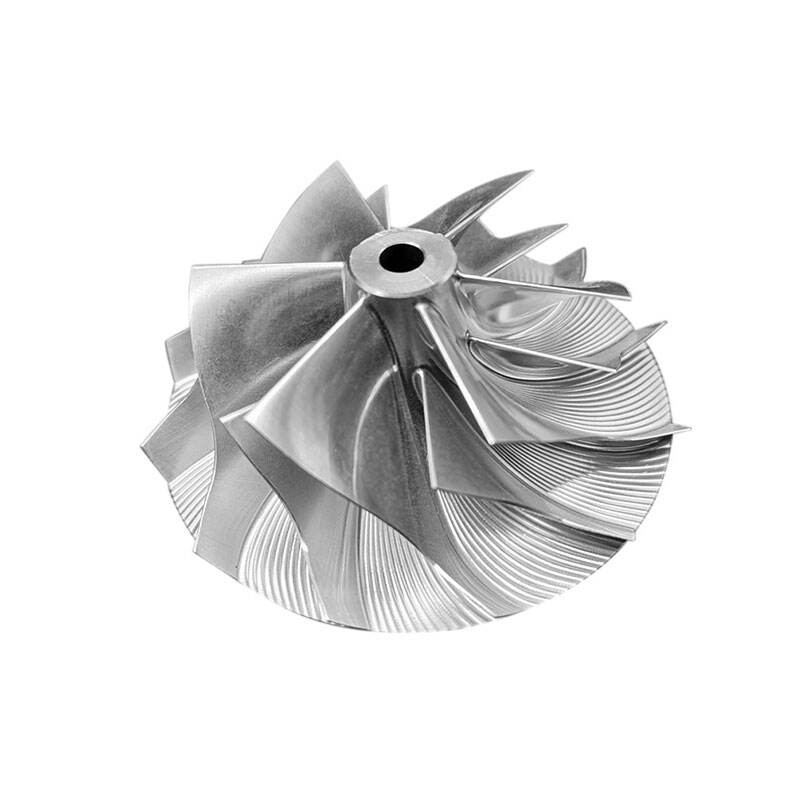

To get the complete picture of O.B.T nozzles, we must have knowledge on steam turbines. The turbine, a steam engine of special blades are spun very fast by the steam flowing over and turning them. Blades are connected to the shaft, a long rod that makes electricity. The steam comes from powerful boilers which heat water to high pressure steam that is used in the turbine. It is this high pressure which causes the blades to turn and turbine to rotate. This is why steam flow control signals are of extract importance to properly generate energy from the turbine.

Nozzles are a very critical part because they help regulate the flow of steam in the turbine. A nozzle is a high-pressure steam to be depressurized so that it can move. It does so by creating a nozzle turbine opening, which is smaller than the pipe where steam life, in essence. By passing the steam through the nozzle and jetting it out, it is moving at a very high velocity which results in much lowered pressure The nozzle also controls the steam flow and sends it to the turbine blade. It ensures a proper force can be applied to get the maximum amount of energy out of steam.

Nowadays the nozzles in modern steam turbines are designed for high efficiency and performance. They have differed in size and layout over the years as new technology has come out. The nozzle in turbine design needed to create the highest energy achievable by optimizing pressure and steam flow. Engineers spend considerable time and effort designing nozzles to match specific turbine types and steam conditions.

Poor use of steam means waste of large quantities of energy, with high negative environmental and financial impact per tonne. The nozzle makes sure that the steam passes through the turbine in a streamlined manner. This can lead to a decrease in the amount of energy it contains, if steam leaks from the O.B.T gas turbine fuel nozzle is released without correct regulation. As a consequence, less energy can be extracted from the steam than what is possible. This is the second in a series of answers to common questions about steam turbines.

Our company can provide customized services and is able to fabricate turbine components from an array of high-temperature alloys in accordance with the requirements of customers. No matter what Nozzle in steam turbine, size or performance requirement, we can achieve it with our flexible production process and cutting-edge technology for process. We work closely with clients to comprehend their needs as well as the various scenarios they might encounter and give them professional assistance and suggestions. We have a variety of materials and processing capabilities to meet the unique requirements of different industries and applications. We aid our clients in improving their competitiveness on the market by offering custom-designed services that improve efficiency and lower costs.

Our company is able to fabricate highly precise and stable turbine components through casting, forging and CNC machine processes. The casting process permits us to Nozzle in steam turbine with complex shapes and high durability, while the forging process gives the parts better mechanical properties and longer lasting. CNC cutting-edge technology, on contrary, provides the highest precision and accuracy of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have an experienced technical team who continuously carry out technological innovation and process improvement to make sure that our products are always at the top of the industry in terms of technology. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continually.

Our company adheres to strict quality standards to ensure the highest quality and the reliability of every component Quality control is carried out throughout the entire process of production from the acquisition of raw materials to the testing of the final product We also perform regular quality Nozzle in steam turbine and adjustments to ensure constant improvements in product quality Our goal is to win the trust and long-term cooperation of our clients by offering high-quality products and to become a leader in the industry

Our complete customer service package includes pre-sales consultation technical support and after-sales assistance to ensure our customers have the best possible experience When it comes to the pre-sales phase our experienced team will understand the customer's needs in detail and provide the most suitable suggestions and solutions In terms of technical support we offer full guidance from product selection until installation and commissioning to ensure that our customers use our products efficiently When it comes to after-sales service we have developed an Nozzle in steam turbine service system that can respond swiftly to customer issues as well as needs and provide quick and effective solutions We want to create long-lasting relationships with our customers and gain their trust and appreciation by offering high-quality services