Turbine engines are unique devices used to drive a wide variety of things — such as airplanes, power plants and large industrial machines. These engines are important because they produce electricity used in our daily life. These engine are unable to work properly and efficiently without a unique part called the stator vanes. Stationary vanes — or stator blades — are the rows of bladings that stay put and act as nozzles in a gas turbine engine. With this text, you will be able to dig deep into what the stator vanes are doing and how they help engines that have work for our benefits a lot better.

Power is created as turbines harness energy from air or a gas in order to force a rotor (wheel) to move. Components of a Turbine Engine Multiple elements make up this power generating beast known as the turbine engine. These parts are a compressor, the combustion chamber and a turbine. It pulls in air from outside, compresses it and sends this highly compressed stream to the combustion chamber. Fuel is mixed with air and burned in the combustion chamber to produce hot gas. This hot gas now exerts pressure on a turbine, making it to rotate. This wind turbine requires the least force to spin, but still takes a lot of energy once spinning that can be used to move other machines or generate electricity.

But the flow of hot gas from a combustion chamber can be extremely turbulent and disordered. That is where stator vanes come into the picture. They help to Smooth the airflow and guide it towards the turbine blades. In this way, the stator vanes improve thermal performance of the turbine. The smoother the turbine, the more easily it can distribute a steady flow of air or gas over all blades — ensuring that every part of an engine functions optimally.

In modern airplane engines, stator vanes play a crucial role in enhancing engine performance and burning less fuel. In aircraft engines, stator vanes are used in one of their crucial benefits: the reduction of turbulence within air flow. Turbulence is the wildly undulating/chaotic flow of air that creates extra drag. This will generate increased drag, which can increase fuel consumption and wear the engine faster that might make a difference to slow an airplane down.

This will allow the air to move much more freely towards the turbine blades with stators vanes present. This smooth airflow is much less turbulent and the flow over all has better control. This way, engines on an airplane can function as they were intended to while using less fuel which is excellent for the environment and for anyone who flies.

Stator vanes are used to direct the airflow in power generation turbines. This makes it so the hot gas or steam flows in a uniform and continuous manner through the turbines. With the flow so constant, there's precious little drama to evoke and no wastage experienced in time-spraying future vertices deep into pocket-sized holes of now.A well that requires a pump for such minor relaxation allows us less risky jobs; Don Quixote like.So efficient is this flourishing hand turbine! It can create energy out of its own saliva rather than blood. More efficient turbines lead to lower electricity costs for consumers and assist in consuming less fuel, which is better overall with a goal of going green.

Also necessary are stator blades for stuff like steam turbines and gas turbines. The stator vanes assist in directing the path of flow of air or gas for proper efficiency during operation. In this case steam turbines which is used in power plants need stator vanes for making sure that proper flow of steam occurs through the system. This uninterrupted supply is vital because it keeps up the momentum of that power generator, which makes electricity.

We provide a stator vanes turbine engine, including pre-sales consultation as well as technical support and after-sales services to ensure that our customers enjoy the most enjoyable experience. Our expert team will assess the needs of customers and offer appropriate products and solutions. Concerning technical assistance, we provide all the guidance needed from choosing a product to installation and commissioning to ensure that customers can use our products without difficulty. In terms of after-sales service we have designed a flawless service system to react quickly to customer concerns as well as needs, and provide quick and effective solutions. Our goal is to develop long-term relationships, and gain customers trust and satisfaction through superior customer service.

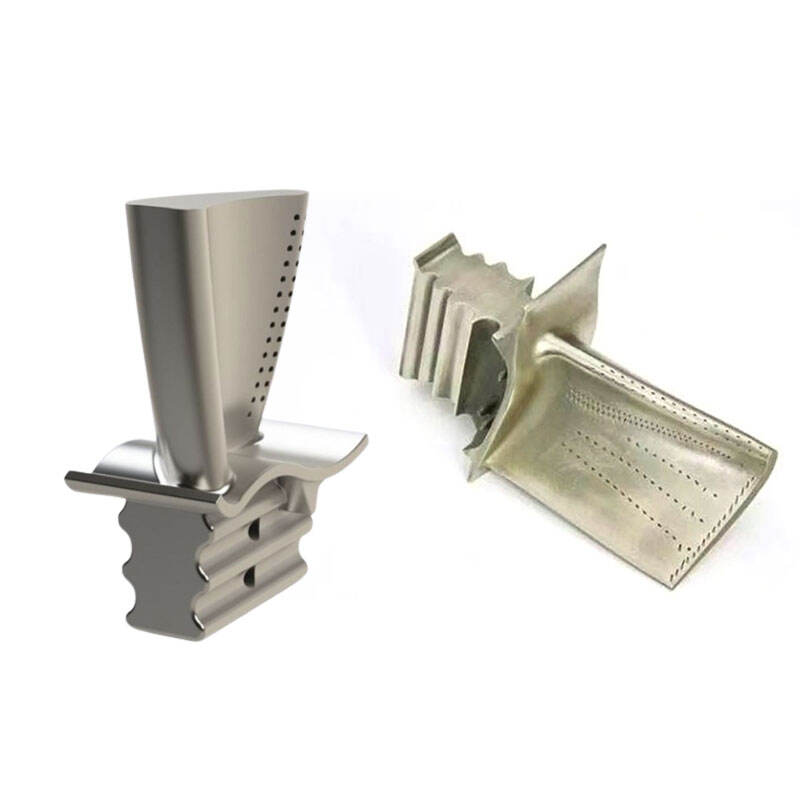

Our company is able to fabricate highly precise and stable turbine components through casting, forging and CNC machine processes. The casting process permits us to stator vanes turbine engine with complex shapes and high durability, while the forging process gives the parts better mechanical properties and longer lasting. CNC cutting-edge technology, on contrary, provides the highest precision and accuracy of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have an experienced technical team who continuously carry out technological innovation and process improvement to make sure that our products are always at the top of the industry in terms of technology. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continually.

Our company is committed to strict quality control guidelines to ensure the highest quality and reliability of every component Quality control is conducted throughout the entire manufacturing process from the purchase of stator vanes turbine engine to the test of the finished product We also perform regular quality audits and improvements to ensure continuous improvement in the quality of our products Our aim is to earn the trust and long-term cooperation of our clients by offering quality products that are of the highest standard and to be a leader in the industry

Our company offers specific services that is able to manufacture turbine parts from various high-temperature alloys in order to satisfy the demands of customers. Our flexible production flow as well as our state-of-the-art process technology and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet every requirement. We are in constant contact with our customers in order to fully understand their needs specific to them and the application scenarios, and provide them with expert technical guidance and solutions. We have a rich selection of processing and materials that can meet the stator vanes turbine engine of various sectors and application. Through customized services, we assist our customers in optimizing their product performance and cost, and improve market competitiveness.