Turbines are crucial in electricity generation at any type of energy plant. Types of devices that work by converting energy into electrical power. I mean what the hell is a turbine stator right? It is a major & vital part of the turbine which generate electricity in case of a power station. Without the stator, turbine will be of no intentions as much relevant.

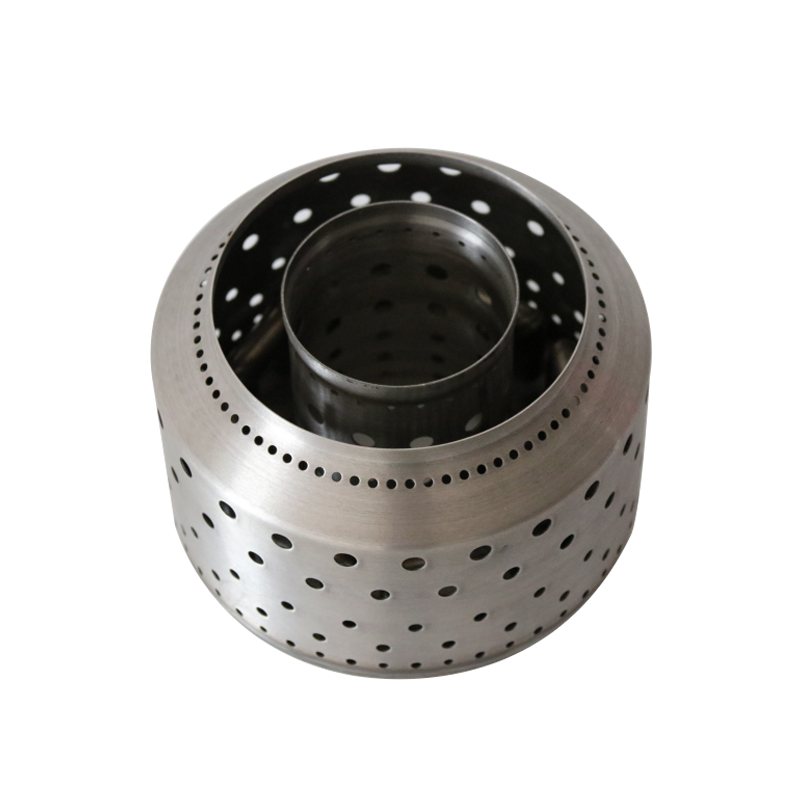

In the turbine stator, there are different components that should be functioning together to make it work properly. The stator is stationary, it holds in place and surrounds another crucial part called the rotor that spins a zone inside. Rotor is spinning to produce electricity (pure photoshopic trickery with these images). The stator is a large circle, or ring and made of strong metal blades that help it do its job.

It is the job of the stator to direct steam at those pins on which turbine blades are mounted. Steam: The gas, produced after boiling water POWER-GENERATING FLOWIf steam exits the stator in an optimal angle; then it transforms also rotor round quickly and lead to production of power. The TURBINE STATOR is an essential part of what helps our homes and business's generate electricity.

Vibration: Vibration is shaking or motion and can be the result of numerous issues but most specifically with its environment--the apparatus surrounding it over time this sort of 'shaking' will cause stator factors function improperly. The vibrations may move the stator, affecting how steam is directed and affects rotor spin. Engineers monitor this vibration using special tools and control it so that is provides a comfortable experience instead of having the motor difficult to operate or less efficient for stator.

It is a modern ancestor of the turbine stator and has developed over many decades. These were just some of the basic and thin-metal blades used in prior stators which are everything besides effective to make power. But contemporary stators have been improved with better materials and designs, such that a new-generation e-motor performs much more effectively than those of yore.

Stator material is tougher now and has shorter lives than a common erosion resistant turbine part, this was much worse. While those materials will degrade eventually, it helps the stator stay conductive longer. Not only that, but engineers are taking advantage of computers and other high-tech tools to make the stator work with as much efficiency and power-driving capability as possible.

The stator in the wind turbine guides air so that it can reach blades. The wind moving the rotor causes those turbine blades to pivot, which results in electricity being produced. Stator part design is one of the most important parts needed to create high megawatts electricity from wind and this needs proper designing. Hence engineers have to properly design stator which can function in an appropriated manner and wind energy is utilized.

We can create turbine parts with high precision and consistency through turbine stator, machining and forging processes. Casting allows us to create parts with intricate designs, strong and durability. Forging gives parts a more durable and superior mechanical property. CNC machining technology, on the contrary, provides the highest precision and accuracy of every part, which reduces the chance of the chance of errors and producing substandard products. Our experienced technical team is always working on technological innovations and process improvements in order to ensure that our products remain at the leading edge of industry technology. We are committed to meeting the demands of our clients for high-performance parts by constantly advancing technology continuously.

We follow turbine stator for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.

Our complete customer service package includes technical assistance pre-sales advice and after-sales assistance to ensure that our customers receive the best experience possible At the time of pre-sales our team of experts will be able to understand the needs of the customer in detail and provide the most appropriate product suggestions and solutions We offer technical assistance from the selection of products through installing and commissioning This guarantees that our customers are turbine stator to use our products without any issues We have a well-developed after-sales system that allows us to respond quickly to customer concerns and issues and provide efficient and prompt solutions We aim to build long-term relationships with our clients and earn their trust and satisfaction by providing quality service

Our company offers specific services that is able to manufacture turbine parts from various high-temperature alloys in order to satisfy the demands of customers. Our flexible production flow as well as our state-of-the-art process technology and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet every requirement. We are in constant contact with our customers in order to fully understand their needs specific to them and the application scenarios, and provide them with expert technical guidance and solutions. We have a rich selection of processing and materials that can meet the turbine stator of various sectors and application. Through customized services, we assist our customers in optimizing their product performance and cost, and improve market competitiveness.