Turbine blades are critical components for many applications. They are used to convert energy from sources like wind, water or steam into useful power. When we consider the way that energy gets produced, turbine blades are doing a lot of the work to ensure that this energy is being made in an efficient manner.

Why Are They a Necessity for Industrial Efficiency

Turbine blades are important for industrial efficiency, as they determine how much energy can be produced. When the wind (or water) rushes underneath the blades, they spin and generate power. If the blades are well-designed, they can catch more energy and convert it into electricity. That means factories are able to work machines and production lines without wasting energy.

Effects of Turbine Blade Design

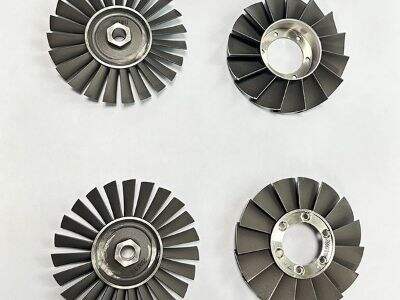

The design of these blades is crucial to how much energy they produce and how much money that saves. When we at O.B.T. design blades for turbines, we consider their shape and size as well as the materials that go into them. For example, long turbine blades can harvest more wind or water and be turned into more power. But the blades have to be strong enough to withstand the forces being exerted on them.

About us

Good design helps ensure that turbine wheel blades can handle a range of conditions, whether in a windy area or a place with strong water currents. This flexibility is useful for sectors which depend on constant generation of energy. It enables them to continue running their operations without any hiccups, saving costs by becoming more efficient.

Innovation

The performance of turbine blades is affected by various factors, particularly when they suffer the action in varying conditions. The material the jet turbine blade are made of is one factor. Blades made of sturdy, yet lightweight materials, can take the stress of spinning fast and stand up to wear and tear.

Benefits

It is crucial to save money on the turbine blades associated with industrial applications and keep them working for long. And among the best ways to do so is through simple maintenance. This will involve you cleaning the blades and examining for wear and tear.

Conclusion

Finally, training personnel to operate and maintain the tur- bine systems is essential. If workers know how to maintain blades, they can do much to prolong their life. Through these steps, companies can ensure they are optimizing the life of their turbine blades and keeping them running strong for years to come.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

IS

IS