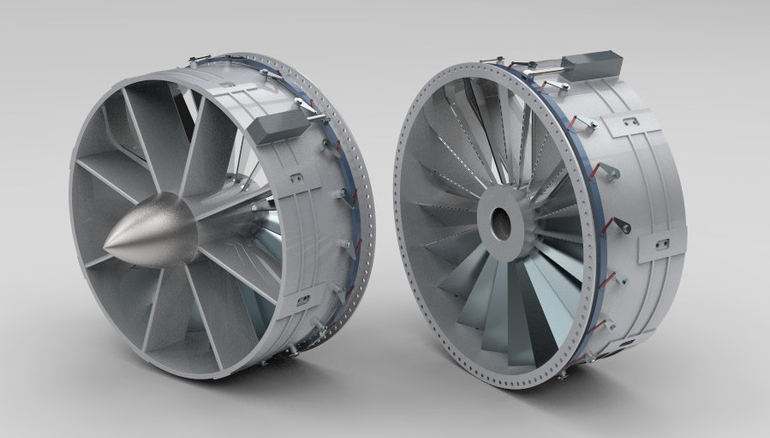

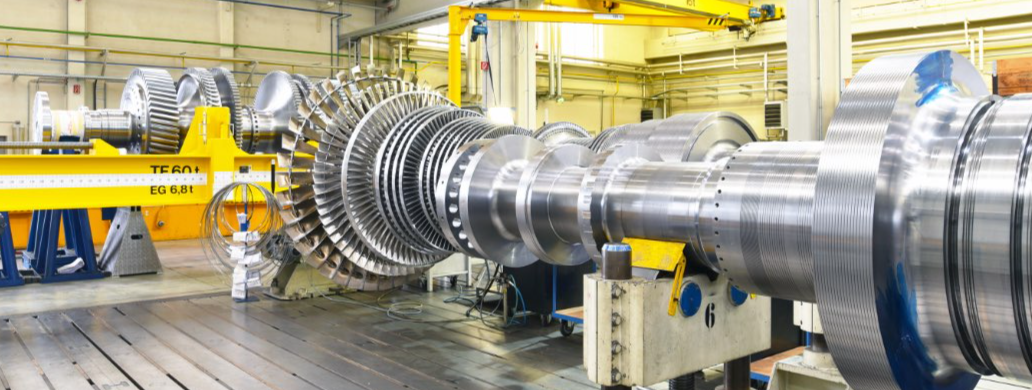

In the heart of a gas turbine, where temperatures soar and pressures peak, a silent guardian operates: the guide vane. These critical components, often overlooked yet essential, direct and control the flow of scorching hot, high-pressure gases, ensuring optimal efficiency, performance, and longevity for these powerhouses. They are the unseen architects of energy transformation, orchestrating the intricate dance of heat and pressure to produce usable power. At BLAZE, we specialize in crafting high-performance guide vanes from Inconel 617, a superalloy renowned for its exceptional heat resistance and strength. Beyond manufacturing, we offer expert reverse engineering capabilities, allowing us to reproduce and optimize even the most intricate guide vane designs. We are more than just manufacturers; we are problem solvers, committed to providing our clients with the most advanced and reliable guide vane solutions, no matter the challenge.

Inconel 617: A Superalloy Tailored for Extreme Environments

Inconel 617, a nickel-chromium-cobalt-based superalloy, represents the pinnacle of materials science, engineered to withstand the most demanding conditions. It is not merely a material; it is a testament to the relentless pursuit of innovation in the face of extreme environments. Its remarkable combination of properties makes it the ideal choice for guide vanes operating within the unforgiving environments of gas turbines, offering unparalleled performance and longevity:

● Unwavering Heat Resistance: Inconel 617 exhibits exceptional thermal stability, maintaining its strength and integrity even at extreme temperatures exceeding 1000°C. This remarkable resistance to high temperatures is crucial for guide vanes, ensuring their reliable performance in the fiery heart of gas turbines. It allows them to withstand the intense heat generated during combustion without compromising their structural integrity, ensuring continued operational efficiency and minimizing downtime.

● Unyielding Creep Resistance: Creep, the gradual deformation of materials under sustained stress at elevated temperatures, is a major concern in gas turbine applications. Imagine a component slowly bending under the constant pressure of extreme heat. Inconel 617 exhibits exceptional creep resistance, maintaining its shape and function over long periods, ensuring consistent performance and reliability. This inherent strength prevents the guide vanes from deforming under the constant pressure of high-temperature gases, guaranteeing their effectiveness and longevity.

● Superior Oxidation Resistance: In the high-temperature environment of gas turbines, materials are prone to oxidation, a process where they react with oxygen and degrade. Imagine a component slowly weakening and crumbling under the relentless attack of oxygen. Inconel 617 stands strong against this degradation, boasting superior oxidation resistance that extends its lifespan and ensures long-term performance. This resistance to oxidation prevents the guide vanes from weakening or becoming brittle, allowing them to maintain their structural integrity and functionality for extended periods.

● Unmatched Corrosion Resistance: Gas turbines operate in environments laden with corrosive gases and elements. Imagine a component being slowly eaten away by the harsh chemicals present in the operating environment. Inconel 617’s inherent resistance to corrosion protects the guide vanes from deterioration, ensuring they remain functional for extended periods, minimizing downtime and maintenance costs. This crucial property ensures that the guide vanes are not affected by the harsh chemicals and gases present in the operating environment, maintaining their performance and extending their lifespan.

Reverse Engineering: Unveiling the Secrets of Design

We understand that not every guide vane is readily available, and that’s where our expert reverse engineering capabilities come into play. We go beyond traditional manufacturing, offering bespoke solutions to meet unique client needs, ensuring that no matter the challenge, we have a solution. This process involves:

● Detailed Analysis: Utilizing advanced 3D scanning and metrology techniques, we create precise digital models of existing guide vanes, capturing every intricate detail. This meticulous process allows us to recreate the exact geometry and dimensions of the original guide vane, ensuring that the new

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

IS

IS