Gas turbines are important devices in power plants, airplanes and myriad other applications. They do so by burning fuel to produce hot gases that spin a turbine. From this revolving we get energy. Like all machines, gas turbines have parts that can wear out or fail. This is where gas turbine spare parts play a role. These replacements, spare parts, are used to swap out old or damaged turbine components so the machine can continue running smoothly. Here at O.B.T we understand the importance of having the right gas turbine spare parts. This information will guide you to lost longer life and overall product cost. Is the high quality of gas turbine spare parts where can I find the best supplier for them?

Here are some points to consider while in search for good quality gas turbine spare parts. Before you order, consider the material. Strength And endurance Parts made with strong materials, such as high-grade steel or special alloy, last longer and can withstand heat better. If a piece is flimsy, it can crack and break easily, causing serious problems for the turbine. Second, look to see if the components have a warranty. Manufacturer's Warranty A good warranty indicates the confidence of the manufacturer in their product. If anything happens, you can replace it at no added cost. Third, make sure to find parts that are designed specifically for your gas turbine model. If a component does not fit properly, it can produce problems when the turbine is running. You’ll also want to check out customer reviews. There is much that can be learned from others' experience about the quality of parts. Lastly, consider the supplier’s reputation. And a company as old as O.B.T probably produces more reliable parts that will last. After all, the correct parts can positively enhance safety and efficiency in terms of gas turbine running.

There are a number of wholesale gas turbine spare parts suppliers that you can trust but it may seem difficult to find them. Start by searching online. Most businesses have websites that display what components they provide. Opt for sellers who have been in the industry for many years, as they are more likely to know and meet customer needs. You can also request recommendations from other businesses in your region, or industry. Connections with other entrepreneurs may also help you find reliable suppliers. Trade fairs are another good way to meet suppliers in person. At these events, you will be able to see the pieces up close and personally speak with those who produce them. O.B.T also participates in trade shows and meets with customers to get up close and personal experience on our products. And remember to ask if the suppliers offer technical support. Decent suppliers should assist you with any questions about the parts. Last, ask for a quote from more than one source. This lets you check prices and shop around for the best offer. Keep in mind what you are looking for is a supplier that will provide quality parts at a fair price.

There are many advantages to using OEM spare parts when it comes to gas turbines. OEM spare parts are the product of the same company that built the gas turbine. Which is to say that they’re made in order to maybe fit just right and possibly play nice with the machine. One of the primary reasons to use OEM parts from our business, O.B.T., is quality. These are also designed with the turbine in mind — so they’re often more reliable and last longer. This can prevent breakdowns and maintain the gas turbine in continued smooth operation for extended periods.

Plus, another added benefit of OEM parts is that they typically are accompanied with a warranty. That means if something breaks down within a certain period of time, the company will repair or replace it for free. This provides peace of mind for the users who are thoroughly protected. Additionally, the OEM parts may contribute to enhancing performance of the gas turbine. And because they fit perfectly, they can help the turbine operate more efficiently. A turbine running efficiently can save on fuel and related costs over time. Turbo Compressor Impeller is one of the key components that benefit from such performance enhancements.

If you are in the market for gas turbine spare parts, there are several potential cost drivers. There are several factors including the type of part required. Some are small and simple, others large and complex. For example, a small gasket might be relatively cheap but not as critical to the system as a component like a turbine blade. The materials from which the parts are made also impact price. Premium materials that can withstand the harshest of temperatures and pressures may be more expensive, but perform better over time.

The market of gas turbine spare parts is constantly evolving due to technology development and new improvements. One of the newest innovations is 3D printing for spares. This system enables companies like O.B.T to make very precise parts at high speeds. Printing in 3-D can cut the amount of time it takes to make a part and also enable production of complex shapes that may be difficult to produce through traditional methods. That means a part can be produced more quickly when it is needed, increasing uptime for gas turbines.

Our company follows strict gas turbine spare parts standards in order to ensure excellent performance and dependability of each component. Quality control is conducted throughout the entire production process beginning with the purchase of raw materials through the test of the finished product. To ensure that the quality of our products is continuously improved, we perform regular audits and improvements. We strive to earn the trust of our clients and their long-term partnership by providing products of high-quality.

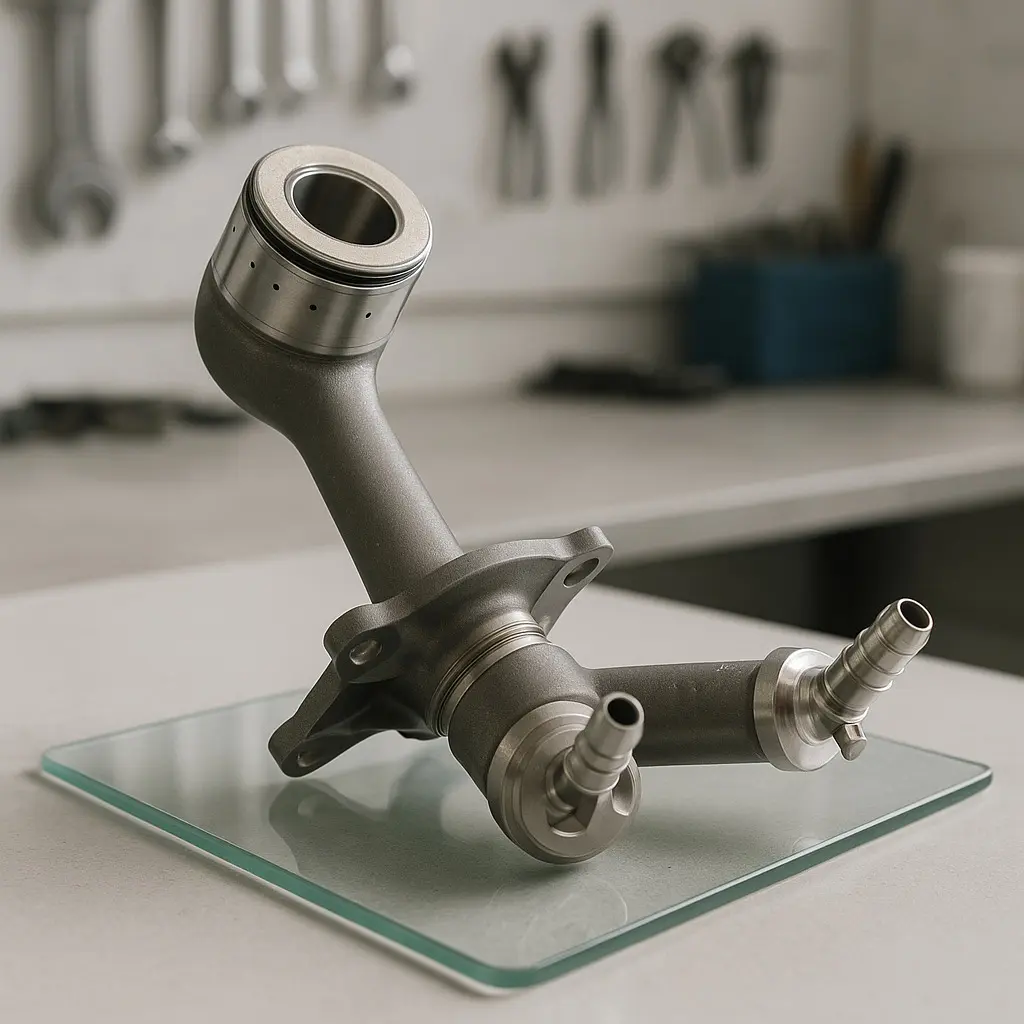

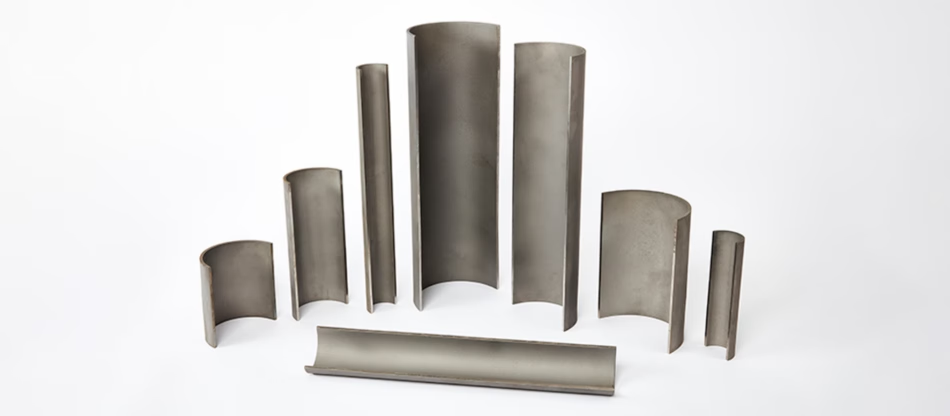

Our company offers custom-designed services and can make gas turbine spare parts in an array of high-temperature alloys in accordance with customer specifications. Whether it is a specific dimension, shape or requirements for performance, we can accomplish it by using our flexible production process and cutting-edge process technology. We collaborate closely with our customers to comprehend their needs as well as the various scenarios they might encounter and then offer them expert assistance and suggestions. Our diverse selection of materials processing capabilities, processing capabilities as well as specific requirements to the application allow us satisfy the specific needs of various industries and application. With customized services, we help our customers optimize the performance of their products and reduce costs, and improve market competitiveness.

We offer a comprehensive customer service which includes pre-sales advice as well as technical support and after-sales support, in order to ensure our customers get the best experience. In the gas turbine spare parts the team's professional staff will understand the customer's needs in detail and provide the most appropriate suggestions for products and solutions. We provide technical support starting with the selection of products, through installing and commissioning. This guarantees that our clients are able to use our products without any problems. We have an established after-sales process that allows us to quickly respond to customer concerns and issues and to offer effective and prompt solutions. We want to create long-lasting relationships with our customers and gain their trust and satisfaction through offering high-quality services.

We can create turbine parts with high precision and consistency through gas turbine spare parts, machining and forging processes. Casting allows us to create parts with intricate designs, strong and durability. Forging gives parts a more durable and superior mechanical property. CNC machining technology, on the contrary, provides the highest precision and accuracy of every part, which reduces the chance of the chance of errors and producing substandard products. Our experienced technical team is always working on technological innovations and process improvements in order to ensure that our products remain at the leading edge of industry technology. We are committed to meeting the demands of our clients for high-performance parts by constantly advancing technology continuously.