टर्बाइन इंजन विशेष उपकरण हैं, जो कई चीजों को चलाने के लिए उपयोग किए जाते हैं — जैसे विमान, बिजली की प्लांट और बड़े उद्योगी यंत्र। ये इंजन महत्वपूर्ण हैं क्योंकि वे हमारे दैनिक जीवन में उपयोग की जाने वाली बिजली उत्पन्न करते हैं। इन इंजनों को सही और कुशल ढंग से काम करने के लिए एक विशेष भाग, जिसे स्टेटर वेन कहा जाता है, की आवश्यकता होती है। स्थिर वेन — या स्टेटर ब्लेड्स — गैस टर्बाइन इंजन में नॉजल के रूप में काम करने वाले ब्लेडिंग के पंक्ति होते हैं। इस पाठ के साथ, आप स्टेटर वेन क्या कर रहे हैं और वे हमारे लाभ के लिए काम करने वाले इंजन को कैसे बेहतर बनाते हैं, इस पर गहराई से चर्चा करने में सक्षम होंगे।

जब टर्बाइन हवा या गैस की ऊर्जा को उपयोग करके एक चक्री (पहिया) को घुमाने के लिए शक्ति प्रदान करती है, तो विद्युत का उत्पादन होता है। टर्बाइन इंजन के घटक इस शक्ति उत्पादन वाले जानवर जिसे टर्बाइन इंजन कहा जाता है, उसमें कई तत्व शामिल हैं। ये भाग एक कंप्रेसर, दहन कक्ष और टर्बाइन हैं। यह बाहरी हवा को अंदर खींचता है, इसे संपीड़ित करता है और फिर इसे दहन कक्ष में भेजता है। दहन कक्ष में ईंधन को हवा के साथ मिलाकर दहाया जाता है जिससे गर्म गैस का उत्पादन होता है। यह गर्म गैस अब टर्बाइन पर दबाव डालती है, जिससे यह घूमने लगती है। यह पवन टर्बाइन सबसे कम शक्ति की आवश्यकता होती है लेकिन फिर भी घूमने के बाद इसमें अन्य मशीनों को घुमाने या विद्युत उत्पन्न करने के लिए बहुत सी ऊर्जा शामिल होती है।

लेकिन एक ज्वाला कक्ष से गर्म गैस का प्रवाह अत्यधिक उथल-सीथल और अनियमित हो सकता है। यहीं पर स्टेटर वेन की भूमिका आती है। वे हवा के प्रवाह को सुचारु बनाने में मदद करते हैं और उसे टर्बाइन ब्लेड्स की ओर मार्गदर्शित करते हैं। इस तरह, स्टेटर वेन टर्बाइन के ऊष्मीय प्रदर्शन में सुधार करते हैं। जितना टर्बाइन सुचारु होगा, उसे सभी ब्लेड्स पर स्थिर हवा या गैस का प्रवाह वितरित करना आसान होगा - यह सुनिश्चित करता है कि इंजन का हर हिस्सा अपनी अधिकतम क्षमता पर काम करे।

आधुनिक हवाई जहाज़ों के इंजनों में, स्टेटर वेन इंजन के प्रदर्शन में सुधार करने और कम ईंधन खपत करने में महत्वपूर्ण भूमिका निभाते हैं। हवाई जहाज़ों के इंजनों में, स्टेटर वेन का एक मुख्य फायदा हवा के प्रवाह में उथल-सीथलता को कम करना है। उथल-सीथलता वायु का अनियमित और उथल-सीथल प्रवाह है जो अतिरिक्त घर्षण उत्पन्न करता है। यह अतिरिक्त घर्षण ईंधन खपत को बढ़ा सकता है और इंजन को तेजी से पहना दे सकता है, जो हवाई जहाज़ को धीमा करने में अंतर पड़ सकता है।

यह हवा को टरबाइन ब्लेड्स की ओर स्टेटर वेन के साथ बहुत अधिक स्वतंत्रता के साथ बहने देगा। यह सूचीबद्ध हवा कम तड़पील होती है और प्रवाह का समग्र नियंत्रण बेहतर होता है। इस तरह, एक विमान पर इंजन अपने उद्देश्य के अनुसार काम कर सकते हैं जबकि कम ईंधन का उपयोग करते हैं, जो पर्यावरण के लिए और उड़ान भरने वाले किसी भी व्यक्ति के लिए उत्तम है।

स्टेटर वेन का उपयोग बिजली उत्पादन टर्बाइन में हवा के प्रवाह को नियंत्रित करने के लिए किया जाता है। यह इस तरह से होता है कि गर्म गैस या भाप टर्बाइन के माध्यम से एक समान और लगातार तरीके से प्रवाहित होती है। प्रवाह इतना स्थिर होने पर, उत्तेजना का बहुत कम अभिव्यक्ति होती है और समय-बर्बादी के भविष्य के शीर्षों को अब के जेब-आकार के छेदों में गहरी तरफ नहीं करना पड़ता है। एक बियर जिसे ऐसी छोटी आराम के लिए पंप की आवश्यकता होती है, वह हमें कम जोखिम वाली कार्यों देती है; डोन क्योखियोट जैसी। इस फूलती हुई हाथ की टर्बाइन की दक्षता! यह अपने ही बदशागीर बजाय खून से ऊर्जा उत्पन्न कर सकती है। अधिक दक्ष टर्बाइन उपभोक्ताओं के लिए कम बिजली की कीमतें देती हैं और कम ईंधन का उपयोग करने में मदद करती हैं, जो पूरे तौर पर हरित लक्ष्य पर पहुंचने के लिए बेहतर है।

स्टेटर ब्लेड भी आवश्यक होते हैं, जैसे स्टीम टर्बाइन और गैस टर्बाइन के लिए। स्टेटर वेन प्रचालन के दौरान सही कुशलता के लिए हवा या गैस के प्रवाह के मार्ग को निर्देशित करने में मदद करते हैं। इस मामले में, विद्युत संयंत्रों में उपयोग की जाने वाली स्टीम टर्बाइन को सुनिश्चित करने के लिए स्टेटर वेन की जरूरत पड़ती है कि सिस्टम में स्टीम का सही प्रवाह हो। यह अविच्छिन्न आपूर्ति जीवनी है क्योंकि यह उस विद्युत उत्पादक की गति को बनाए रखता है, जो बिजली बनाता है।

हम एक स्टेटर वेन्स टरबाइन इंजन प्रदान करते हैं, जिसमें पूर्व-विक्रय परामर्श के साथ-साथ तकनीकी सहायता और उत्पाद के बाद की सेवाएँ शामिल हैं, ताकि हमारे ग्राहकों को सबसे अधिक संतोषजनक अनुभव प्राप्त हो सके। हमारी विशेषज्ञ टीम ग्राहकों की आवश्यकताओं का आकलन करेगी और उचित उत्पादों और समाधानों की पेशकश करेगी। तकनीकी सहायता के संबंध में, हम उत्पाद के चयन से लेकर स्थापना और सुरक्षित संचालन (कमीशनिंग) तक सभी आवश्यक मार्गदर्शन प्रदान करते हैं, ताकि ग्राहक हमारे उत्पादों का उपयोग बिना किसी कठिनाई के कर सकें। उत्पाद के बाद की सेवा के क्षेत्र में, हमने ग्राहकों की चिंताओं और आवश्यकताओं के प्रति त्वरित प्रतिक्रिया देने के लिए एक निर्दोष सेवा प्रणाली की रचना की है, तथा त्वरित एवं प्रभावी समाधान प्रदान करते हैं। हमारा लक्ष्य दीर्घकालिक संबंधों का विकास करना तथा उत्कृष्ट ग्राहक सेवा के माध्यम से ग्राहकों का विश्वास और संतुष्टि प्राप्त करना है।

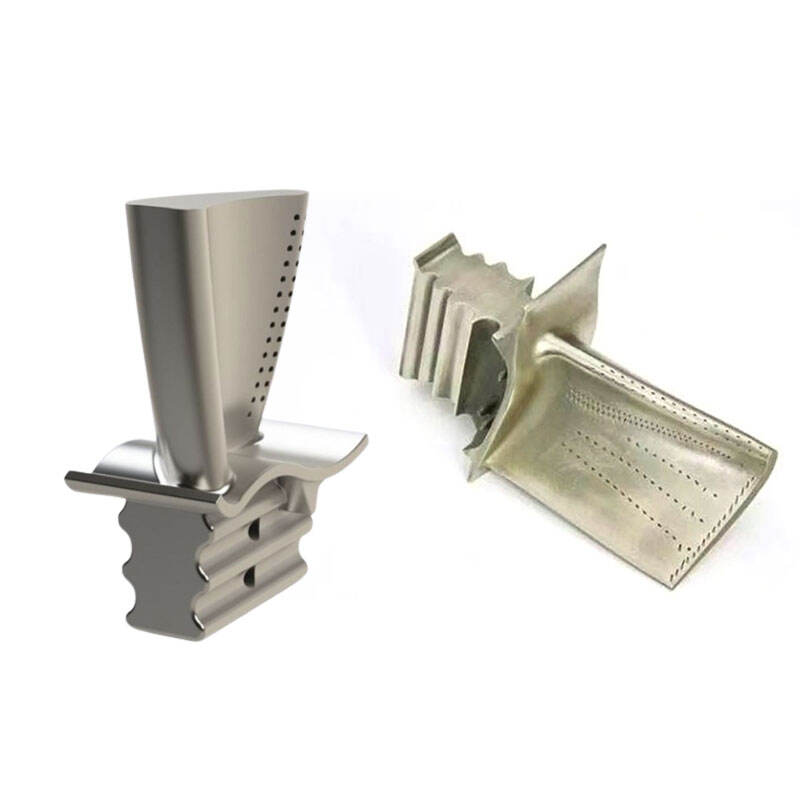

हमारी कंपनी डालना, फोर्जिंग और सीएनसी मशीन प्रक्रियाओं के माध्यम से अत्यधिक सटीक और स्थिर टरबाइन घटकों का निर्माण करने में सक्षम है। डालना प्रक्रिया हमें जटिल आकार और उच्च टिकाऊपन वाले स्टेटर वेन्स टरबाइन इंजन का निर्माण करने की अनुमति देती है, जबकि फोर्जिंग प्रक्रिया घटकों को बेहतर यांत्रिक गुण और लंबे समय तक चलने वाली जीवनकाल प्रदान करती है। इसके विपरीत, सीएनसी कटिंग-एज तकनीक प्रत्येक घटक की उच्चतम सटीकता और शुद्धता प्रदान करती है, जिससे निर्माण त्रुटियों की संभावना कम हो जाती है और खराब गुणवत्ता वाले उत्पादों के उत्पादन का जोखिम कम हो जाता है। हमारे पास एक अनुभवी तकनीकी टीम है, जो लगातार तकनीकी नवाचार और प्रक्रिया में सुधार करती रहती है, ताकि हमारे उत्पाद हमेशा तकनीकी मामलों में उद्योग के शीर्ष पर बने रहें। हमारी प्रतिबद्धता निरंतर तकनीकी विकास के माध्यम से उच्च प्रदर्शन वाले घटकों की ग्राहकों की आवश्यकताओं को पूरा करना है।

हमारी कंपनी प्रत्येक घटक की उच्चतम गुणवत्ता और विश्वसनीयता सुनिश्चित करने के लिए कड़े गुणवत्ता नियंत्रण दिशानिर्देशों के प्रति प्रतिबद्ध है। गुणवत्ता नियंत्रण को स्टेटर वेन्स टर्बाइन इंजन की खरीद से लेकर अंतिम उत्पाद के परीक्षण तक पूरी विनिर्माण प्रक्रिया में किया जाता है। हम उत्पादों की गुणवत्ता में निरंतर सुधार सुनिश्चित करने के लिए नियमित रूप से गुणवत्ता ऑडिट और सुधारात्मक कार्यवाही भी करते हैं। हमारा उद्देश्य उच्चतम मानक के गुणवत्तापूर्ण उत्पाद प्रदान करके अपने ग्राहकों का विश्वास अर्जित करना और दीर्घकालिक सहयोग स्थापित करना है, ताकि हम इस उद्योग में एक अग्रणी कंपनी बन सकें।

हमारी कंपनी विशिष्ट सेवाएँ प्रदान करती है जो ग्राहकों की आवश्यकताओं को पूरा करने के लिए विभिन्न उच्च-तापमान मिश्र धातुओं से टरबाइन के भागों के निर्माण की सुविधा प्रदान करती हैं। हमारी लचीली उत्पादन प्रक्रिया, अत्याधुनिक प्रक्रिया प्रौद्योगिकी, और आकार एवं आकृति जैसी विशिष्ट आवश्यकताओं के साथ-साथ प्रदर्शन संबंधी आवश्यकताओं को पूरा करने की क्षमता के कारण हम प्रत्येक आवश्यकता को पूरा करने में सक्षम हैं। हम अपने ग्राहकों के साथ निरंतर संपर्क में रहते हैं ताकि उनकी विशिष्ट आवश्यकताओं और अनुप्रयोग परिदृश्यों को पूरी तरह से समझा जा सके, और उन्हें विशेषज्ञ स्तर की तकनीकी मार्गदर्शन एवं समाधान प्रदान किए जा सकें। हमारे पास प्रसंस्करण और सामग्रियों का एक विस्तृत चयन उपलब्ध है, जो विभिन्न क्षेत्रों और अनुप्रयोगों के लिए स्टेटर वेन्स टरबाइन इंजन की आवश्यकताओं को पूरा कर सकता है। अनुकूलित सेवाओं के माध्यम से, हम अपने ग्राहकों की उत्पाद प्रदर्शन और लागत के अनुकूलन में सहायता करते हैं तथा उनकी बाज़ार प्रतिस्पर्धात्मकता में सुधार करते हैं।