In 1st century AD, lived a great person, Hero of Alexandria. He created the first steam turbine. This one is actually pretty significant because this invention helped to produce something called a turbine disc The turbine disc itself is one of the key components in a wind-tunnel. It has also a great part in making the engine run well and last long that are two essential specifications of many machines.

THE LIFE OF HERO OF ALEXANDRIA - Hero of Alexandria lived in the 1st Century AD. He was a Greek inventor, he loves inventing new things. One of those inventions was making a ball or tube spin by steam power, which worked great. This was the first example of what we now refer to as a modern turbine engine. But then we see yet another inventor, by the name of Giovanni Branca in 1629. Developing a steam turbine that led to sweating of the poor in mills making bread. A half-century later, in 1884 it was Charles Parsons who created the very first steam turbine that worked really well. So there originated a superb method of generating power in these turbine engines; and therefore, it became one of the best sought after thing. Those turbine engine were now so common that engineers spent a great deal of effort in designing strong enough discs to contain the high heat and pressure from how powerful running these engines became.

Understanding how the turbine disc operates requires a high-level understanding of various components in the turbine engine. A gas turbine engine consists of a stator, rotor, combustor and compressor among other critical parts. The rotor is the center of one's shaft and has a few rings in it that have cuts into them. These are groves that holds the blades. We call these rings discs. The rotor in turn is connected to a downstream consumer, since the turbine discs are fixed on it.

Turbine discs must be made out of materials that are both strong and able to withstand high temperatures. In the majority of cases these discs are manufactured from special nickel-based alloys. These materials need to withstand the extremly high heat and pressure inside an engine. Turbine discs have to function at temperatures of up 700°C, so they are typically constructed from titanium in modern engines.

Titanium's lightness and strength make it a truly unique metal. Unlike some of the materials used in construction (like polypropylene or brass), PVC is incredibly tough — it not only handles extreme heat and pressure without a worry, but also does not readily rust. The class of titanium alloys that the turbine disc is constructed from include Ti-6AL-4V and Ti-6AL-2SN3ZR 0.5MO These are substances which are designed to work even in very harsh conditions and still be strong enough for their purpose.

There is much innovation and new ideas are being developed to make engines/turbines even better than ever with advanced turbine disc designing. Turbine discs are protected by new technologies, such as nano-coatings and special high-temperature ceramics. This type of new coatings can withstand high temperatures and is very abrasion-resistant, which reduces the amount of maintenance that will be needed and lower costs.

In addition, novel manufacturing processes like additive layer manufacture are being used to create turbine disks that have intricate shapes and features. This equates to turbine discs that are both lighter in weight and stronger, enabling them to better cope with the rigours of use. This is nice because it spans when fuel is wasted and reduces pollution which in turn of course takes good care to the earth.

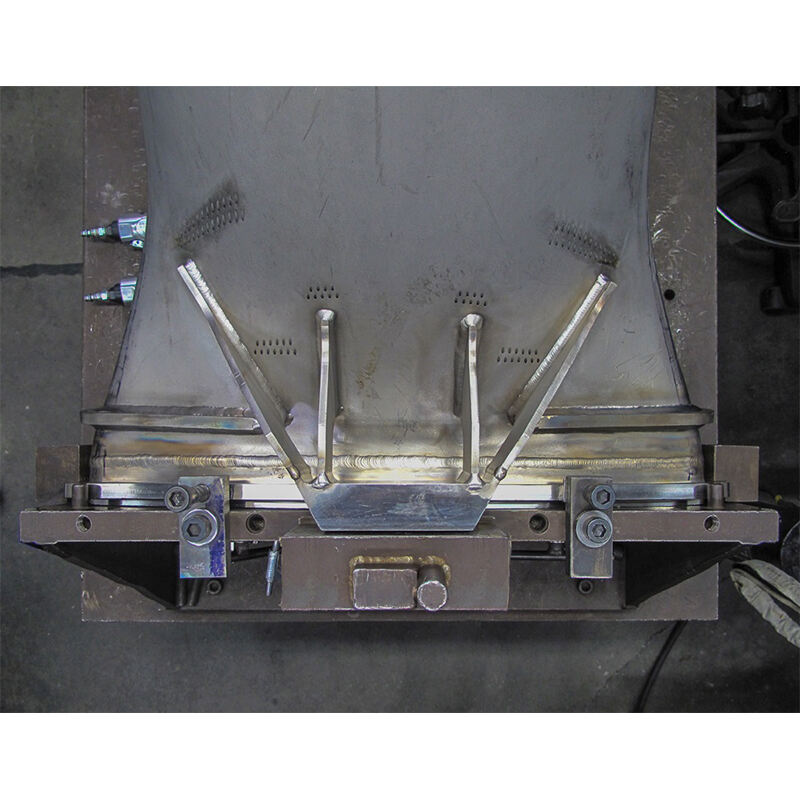

Our company can fabricate highly precise and stable turbine parts through casting forging, and CNC machining. Casting allows us to create components with complex forms, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC technology for machining, on other hand, ensures high precision and consistency of every part, which reduces the chance of the chance of errors and producing substandard products. Our technical team that constantly carries the latest technological advancements and process improvement to make sure that our products are always at the top of the industry in terms of turbine disc. We're determined to meet our customers' demands for high-performance turbine components through continuous technological advancement.

Our company adheres to strict quality control guidelines to ensure excellent performance and turbine disc of every component. Quality control is carried out throughout the entire process of production beginning with the purchase of raw materials to the test of the finished product. We also regularly conduct quality audits and adjustments to ensure constant enhancement of the product's quality. Our goal is to win the trust and cooperation of our customers by providing high-quality products and to become an industry leader.

Our complete customer service package includes pre-sales consultation technical support and after-sales assistance to ensure our customers have the best possible experience When it comes to the pre-sales phase our experienced team will understand the customer's needs in detail and provide the most suitable suggestions and solutions In terms of technical support we offer full guidance from product selection until installation and commissioning to ensure that our customers use our products efficiently When it comes to after-sales service we have developed an turbine disc service system that can respond swiftly to customer issues as well as needs and provide quick and effective solutions We want to create long-lasting relationships with our customers and gain their trust and appreciation by offering high-quality services

Our company offers customized services and is able to fabricate turbine components from many different high temperature alloys based on customer specifications. Our flexible production flow along with our advanced process technology and our capability to meet turbine disc, such as size and shape, as well as performance can allow us to meet any requirement. We work closely with clients to comprehend their needs and the potential scenarios for their applications, and then give them professional guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements for applications allow us to fulfill the particular requirements of various industries and application. With our customized services, we help our customers optimize efficiency and costs of their products, and improve market competitiveness.