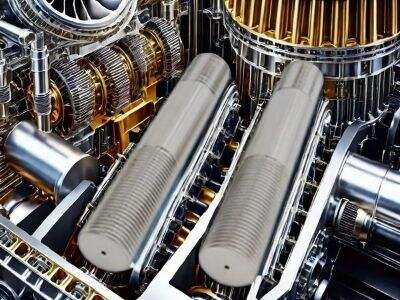

ייצור חלקים לטורבינות הוא משימה קריטית בייצור. חלקים אלו משמשים בהרבה דברים, כגון מטוסים ותחנות כוח. יצרנים חייבים להיות מאוד מדוייקים כדי להבטיח שהחלקים יעבדו היטב. O.B.T יודעת כיצד לייצר את הרכיבים האלה בדיוק גבוה. יכולות העיבוד המתקדמות שלנו מאפשרות לנו לייצר חלקים לטורבינות באיכות גבוהה. במאמר זה נדון במה שחשוב לקחת בחשבון בעת בחירת ספקים לרכיבים אלו וכיצד עיבוד מדויק משפר את איכות כל רכיב שייצרנו

כאשר מדובר בבחירת יצרני רכיבי טורבינה, יש כמה דברים שכדאי לשאת בלב

ראשית, תצטרכו לזהות ספקים ידועי שם. הם חייבים להיות ידועים בכך שהם מבצעים עבודה טובה לפי ה lịchון הסוכם. ניתן לקרוא ביקורות באינטרנט או לשאול חברות אחרות על החוויות שלהן. שנית, שימו לב לסוג החומרים שהספק משתמש בהם. איכות החומרים קריטית במיוחד לרכיבי טורבינה, בדיוק בגלל שהם ייחשפו לתנאים קיצוניים כמו חום ולחץ. גם כדאי לבדוק איזה טכנולוגיה הספק משתמש בה. חברות כמו O.B.T משתמשות במכונות ובתוכנות העדכניות ביותר כדי להבטיח דיוק. כמו כן, משתלם למצוא מקור המסוגל לספק פתרונות מותאמים אישית. לפעמים אולי תרצו חלקים מותאמים אישית שאינם תקניים. ספק טוב יהיה מוכן להתאים. בנוסף, תקשורת היא עניין מרכזי. עליכם להרגיש שאתם יכולים לדבר עם הספק שלכם על הצרכים שלכם, או על כל דבר שמתרחש לא כמתוכנן. לבסוף, קבלו הצעת מחיר אך אל תניחו שהזולה ביותר היא הטובה ביותר. איכות צריכה לבוא ראשונה. איתור ספק שיש לו את כל אלה יכול לעזור לכם להבטיח שתקבלו את רכיבי הטורבינה הטובים ביותר לשימוש שלכם

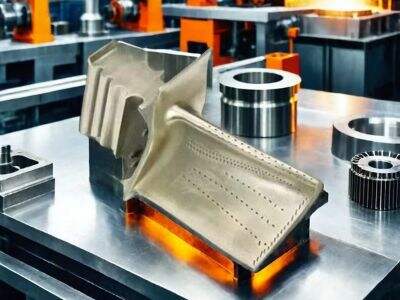

תהליכים מתקדמים לעיבוד חומר נדרשים כדי לשפר את איכות חלקים של טורבינות

זוהי הטכנולוגיה שמאפשרת לנו לעבד חלקים בדיוק מרהיב. לדוגמה, טכנולוגיות כגון CNC (בקרת ממונח מחשב) עיבוד מאפשר לנו לייצר צורות מורכבות שקשה מאוד לייצר באמצעות כלים ידניים. מכונות אלו עוקבות אחר הוראות מדויקות, עד עשירית המילימטר בחלק מהמקרים, ומייצרות חלק אחרי חלק באופן זהה לחלוטין, ובכך מקטינות טעויות בצורה משמעותית. עיבוד מתקדם משפר גם את גימור הפנים של רכיבי הטורבינה. פני השטח של החלק חייבים להיות חלקים, כיוון שצלעות מחוספסות עלולות ליצור בעיות כאשר החלקים בשימוש. יתרון נוסף הוא האפשרות להשתמש בחומרים בעלי ביצועים גבוהים בשיטה זו. ניתן לה employs סגסוגות וחומרים מרוכבים בעלי חוזק גבוה, אשר מאפשרים לרכיבים להיות קלים יותר אך עם עמידות טובה יותר. טורبينים, במיוחד, יכולים להפיק תועלת רבה מחלקים קלים יותר שעשויים להפוך אותם ליעילים יותר. שנית, תהליכי עיבוד מורכבים יכולים לצמצם פסולת. טכניקות מסורתיות עלולות ליצור פסולת שמשליכים לפח, אך בעזרת יכולת העיבוד המדויקת, נוכל להשתמש בחומר בצורה יעילה יותר." זה ידידותי לסביבה ויחסוך כסף. לסיכום, O.B.T יכולה לייצר רכיבי טורבינה איכותיים על ידי אימוץ תהליך עיבוד מתקדם, שהם אמינים ויעילים עבור מגזרי התעשייה כיום

למה עיבוד מתקדם הוא קריטי לרכיבי טורבינה מדויקים

רכיבי טורבינה חשובים ביותר לעיבוד מתקדם. טורבינה היא מכונה שתרום לייצור אנרגיה, כמו אלו בתחנות כוח או במטוסים. למכונות האלה יש הרבה רכיבים שצריכים להתאים בצורה הדוקה זה לזה. אם חלק אחד לא מיוצר בדיוק, הטורבינה כולה עלולה לפעול בצורה לקויה או אפילו להישבר. בשיטות עיבוד מתקדמות משמשים בכלים ובטכנולוגיות מיוחדות כדי לבנות את החלקים הללו בדיוק רב. למשל, חלק מהמכונות של ימינו מסוגלות לגזור מתכת בדיוק כזה שיוצר פרטים זעירים שקשה להבחין בהם. זה חשוב במיוחד מכיוון שרכיבי טורבינה פועלים בתנאי לחץ וחום. ייתכן שהם לא יהיו חזקים מספיק כדי לעמוד בתנאים הללו אם לא ייוצרו בדיוק. בחברה O.B.T אנו מיישמים עיבוד מדויק עיבוד שיטות שמאפשרות לנו לייצר חלקים מדויקים של טורבינות. טכניקה בסיסית בה אנו משתמשים היא עיבוד בקרה מספרית ממוחשבת (CNC). זה אומר שהכלים המשמשים לחתוך ולעצב את המתכת נשלטים על ידי מחשב. זה מאפשר עיבוד מורכב מאוד, כדי להבטיח שכל חלק מיוצר בדיוק כפי שהוא צריך להיות. זה לא רק משפר את איכות החלקים, אלא גם מאיץ את תהליך הייצור. אנו מייצרים רכיבי טורבינה באמצעות עיבוד מתקדם; אנחנו יכולים לייצר כמויות גדולות, כולן באותם ממדים בדיוק. זה גורם לטורבינות להסתובב בצורה קלה ויעילה יותר, מה שטוב לייצור אנרגיה. לסיכום, עיבוד מתקדם הוא חיוני כדי להבטיח שחלקי הטורבינה יהיו מדויקים ואמינים

עיבוד רכיבי טורבינה: דעות שגויות נפוצות שנסדקו. טורבינות משמשות בצורה נרחבת ליצירת חשמל

יש הרבה שגיאות בנוגע לאופן שבו מייצרים חלקים לטורבינות. אחד המיתוסים הפופולריים הוא שמכונת עיבוד היא דרך קלה. יש כאלה שנראה שהם חושבים שמספיק רק לחתוך מתכת, והנה. אבל ייצור של חלקים לטורבינה הוא הרבה יותר מורכב. זה מאתגר טכנית: נדרשת ידע מקיף בחומרים, בכלים ובהנדסה. ב-O.B.T אנחנו מבינים את החשיבות של עשיית כל דבר נכון בדיוק. עוד שקר הוא שהעיבוד המתקדם הוא לא יותר מאשר מהירות. אם כי מכונות מתקדמות יכולות לייצר חלקים במהירות, עדיפות עיקרית ניתנת לאיכות. ברור, ייצור מהיר זה דבר טוב; אך אם החלקים לא מיוצרים כראוי, זה עלול לגרום לכאבי ראש בהמשך. יש אפילו כאלה שחושבים שכל כלי הפעימה דומים. כמובן, שלכל מכונה יש תכנון שונה עבור עבודות שונות. עבור חלקים של טורבינה, אנו לעתים קרובות משתמשים בכלים מיוחדים שיכולים לעבד חומרים קשיחים וסובלנות הדוקות כנדרש. יש גם תפיסה שמדובר בעיבוד מתקדם שהוא יקר מדי. אם כי זה עלול להרגיש יקר בתחילה, חלקים איכותיים יחזיקו הרבה זמן יותר ויחסכו כסף לאורך זמן. לחלקים טובים של טורבינה אין צורך בתיקונים ובשינויים רבים. כלומר, חברות יכולות להרוויח מהשקעה בעיבוד מתקדם אם הן מחפשים לצמצם עלויות לאורך זמן. ידע עובדות על עיבוד רכיבי טורבינה קונים יכולים לקבל החלטות מושכלות יותר כשמדובר ברכישת רכיבי טורבינה

יתרונות עיבוד מתקדם שקונים סיטונאים צריכים לדעת

למה קונים סיטונאים צריכים להיות מודעים לעיבוד מתקדם לרכיבי טורבינה, ראשית כל הרכיבים הללו מיוצרים בדיוק גבוה. כלומר, הם מתאימים היטב זה לזה ופועלים ביעילות. כאן בחברת O.B.T, אנו מתמחים בייצור מוצר איכותי המתאים לצרכים של הלקוחות שלנו. לכן כשאתם קונים רכיבי טורבינה מעיבוד מתקדם, אתם קונים אמינות. זהו דבר חשוב כשמדובר במכונות הנמצאות תחת לחץ גבוה. יתרון נוסף הוא שהעיבוד המתקדם עיבוד ניתן להתאים ליישום הספציפי. בחרו את החלקים בהתאם למה שאתם צריכים במונחי גודל וצורה (קל ללקוח לבקש מידות שונות או צבעי חומר גלם). גישה זו של 'גודל אחד לכולם' ניתנת להתאמה לצרכים העסקיים שלכם כדי להשיג בדיוק את מה שאתם צריכים לפרויקטים שלכם. בנוסף, עיבוד מתקדם יכול לשפר את הביצועים. אם ניתן לבנות חלקים של טורבינה בצורה מדויקת יותר, הטורבינה כולה תפעל בצורה יעילה יותר. זה יכול להוביל לחסכון בחשבונות האנרגיה ולإنتاجיות גבוהה יותר. קיימות גם אפשרויות אספקה מהירה יותר באמצעות עיבוד מתקדם. ומכיוון שמכונות מודרניות יכולות לייצר חלקים במהירות, הלקוחות מקבלים את הזמנותיהם מהר יותר מאשר בשיטות מסורתיות. זה חשוב במיוחד בתעשיות שבהן הזמן הוא קריטי. באופן כללי, הקונים בסיטונאות צריכים לדעת שבבחירת עיבוד מתקדם לרכיבי טורבינה מדובר באפשרות חכמה. זה מביא לחלקים איכותיים, אמינים ויעילים שיכולים לשפר את יעילות העבודה עם ערך עמיד לאורך זמן

תוכן העניינים

- כאשר מדובר בבחירת יצרני רכיבי טורבינה, יש כמה דברים שכדאי לשאת בלב

- תהליכים מתקדמים לעיבוד חומר נדרשים כדי לשפר את איכות חלקים של טורבינות

- למה עיבוד מתקדם הוא קריטי לרכיבי טורבינה מדויקים

- עיבוד רכיבי טורבינה: דעות שגויות נפוצות שנסדקו. טורבינות משמשות בצורה נרחבת ליצירת חשמל

- יתרונות עיבוד מתקדם שקונים סיטונאים צריכים לדעת

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

IS

IS