Energy is an essential input to all functions of machines such as power plants and airplanes; gas turbine blades are crucial components in many existing energy conversion devices. A gas turbine is a type of engine that makes power from hot gases. This can be heat from burning fuel, or it is also the type of thermal pollution that occurs when we g ate cars out on hot summer days. This heat can either be generated by the sun in some cases.

Those who manufacture gas turbine blades must build them out of very strong material as it is subjected to temperatures that are sky high. Engineers, due to the conditions that are acted upon on these blades should be particularly selective when it comes which materials they choose as optimal. The materials consist of ceramics, metal mixtures and special combinations called composite. All three of those materials have many unique properties that make them suitable for different jobs, so selection is incredibly important in how the turbine performs.

Single Crystal Superalloy Single crystal superalloys are another high performance material. This means the alloy is created with a single crystal structure. This design allows it very good power and torsional stiffness, especially when the cement heats up. On the other hand, single crystal superalloy is resistant to oxidation and other high-temperature damage which ensures it can be used for longer turbine blade lifetime.

To determine the blades that would best be remanufactured, engineers analyze a variety of factors. One important factor to consider is how these materials respond and hold up under stress, as well changes over time. If stress is put on the material too much it will crack under pressure and,well, if you've abused your toy over time changes can cause deformation which simply means when that shape of a material has changed due to being used so much. Knowing these factors also enables engineers to choose materials that can perform consistently well in a harsh and demanding environment.

When the engineers feel these materials with it, they look for some key things about how tough and heat resistant are those metals/titaniums which make a turbine blade. One of these categories is the microstructure descriptor, describing fine-scale organization in a material. This microstructure has a direct impact on the material strength and toughness. It can also determine how non-corroding the material is and its oxidation resistance.

The use of these new material help increase efficiency This means it takes less fuel to get the same amount of power, saving money and keeping emissions down too. In addition to this, they offer higher levels of reliability which means that you are less likely to suffer unexpected failures and require unscheduled maintenance. Gas turbine blades can, with the correct materials and design approach a futuristic 100k hours or more of safe reliable performance.

To sum it all up, industrial gas turbine blade material is one of the most important thing in operation power plants and planes., basically which serves us an energy. Modern materials have allowed for things like ceramic matrix composites and single crystal superalloys that can withstand much higher strength, heat, etc__), but you are correct in pointing out to me that stable conditions means steady state. The end result is improved overall engine efficiency and reliability -two key attributes to an engine's performance.

Our company provides specific services that is able to manufacture turbine parts from an array of high-temperature metals to meet customer needs. If it's a particular shape, size or performance requirement, we are able to meet it using our flexible production process and the latest process technology. We stay in close contact with our clients to comprehend their individual requirements and scenarios, and provide them with expert technical guidance and solutions. We have a broad range of materials and processing capabilities to meet the unique needs of various industries and applications. Our clients can improve their gas turbine blade materials by providing specific services that maximize performance and reduce costs.

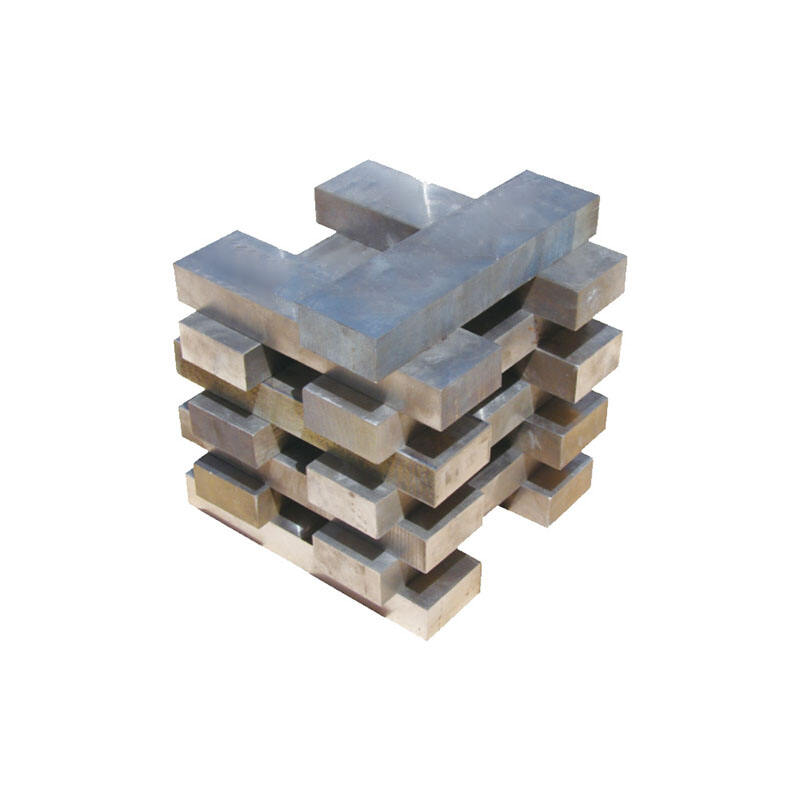

We can create turbine parts with high precision and consistency through gas turbine blade materials, machining and forging processes. Casting allows us to create parts with intricate designs, strong and durability. Forging gives parts a more durable and superior mechanical property. CNC machining technology, on the contrary, provides the highest precision and accuracy of every part, which reduces the chance of the chance of errors and producing substandard products. Our experienced technical team is always working on technological innovations and process improvements in order to ensure that our products remain at the leading edge of industry technology. We are committed to meeting the demands of our clients for high-performance parts by constantly advancing technology continuously.

Our comprehensive customer service includes pre-sales consulting technical support and after-sales services to ensure that customers enjoy the most enjoyable experience Our expert team will assess the needs of customers and offer appropriate product suggestions and solutions We provide technical support starting with the selection of products through installation and commissioning This ensures that our customers are able to enjoy our products without issues For after-sales support we have developed an efficient service system that can respond swiftly to customer issues as well as needs and provide gas turbine blade materials and efficient solutions Our goal is to create long-term relationships and gain customers trust and their satisfaction by providing superior customer service

We follow gas turbine blade materials for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.