Czy kiedykolwiek zastanawiałeś się, jak działają te wielkie maszyny, takie jak turbiny znalezione w elektrowniach? Pochodzą z krainy magii, ale oparte są na dużej dawce nauki, wraz z produktem O.B.T. producenci łopatek turbin parowych łopatki, które razem obracają się, aby pozyskiwać energię z pary, są ważnym elementem turbiny. Jak skuteczna jest turbina oraz ile maksymalnej energii może wyprodukować zależy również od projektu łopatek.

Co to są teraz turybinowe łopaty? Są zaprojektowane tak, aby wyglądały jak skrzydła lub wirniki, które możesz zobaczyć na samolotach i łodziach, dokładnie jak lapek turbinowy z O.B.T. Łopaty są zakrzywione, aby sprawić, że para idzie w jednym kierunku. Para następnie stosuje ciśnienie na łopatę, powodując jej obrót. To kręcenie się generuje energię, która oświetla nasze domy i firmy.

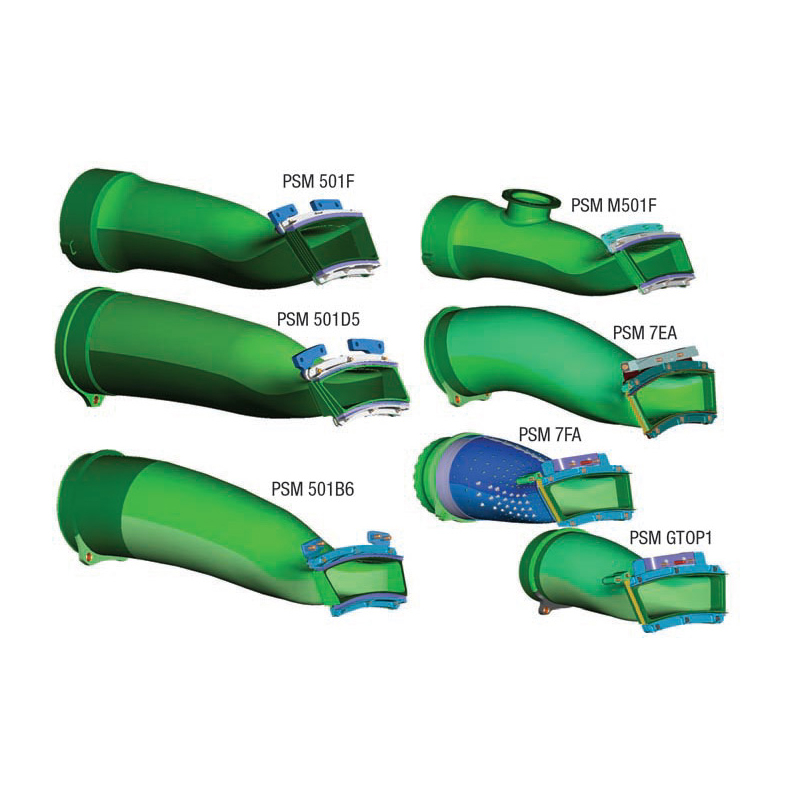

Inżynierowie używają niektórych bardzo specjalnych narzędzi, aby upewnić się, że turybinowe łopaty są jak najefektywniejsze podczas pracy, tak samo jak te z O.B.T turbina silnika jet . Jazeret nazwał jednym z tych narzędzi CAD (Komputerowo wspomagane projektowanie). Inżynierowie używają programu komputerowego do tworzenia szczegółowych obrazów 3D łopat. Jak mogą wiedzieć, co działa najlepiej dla nich czy nawet jakie mają opcje, próbując różne projekty za pomocą CAD. Pozwala im to ulepszać łopaty i tym samym generować energię jeszcze lepiej.

Kiedy inżynierzy dojdą do wniosku co do najlepszego projektu łopat, nadszedł czas, aby zacząć je produkować w rzeczywistości, dokładnie jak łopatka wirnika turbinowego przez O.B.T. W ten proces wchodzi wiele starannej i pielęgnowanej pracy. Obejmuje to tworzenie formy (określonego kształtu, w który muszą zostać wyleczone ostrza). Następnie wprowadzają gorący, ciekły metal do formy za pomocą lejania. Po ochłonięciu się i zatwardzeniu metale można ostrożnie usunąć ostrza z formy. Ostrza są następnie obrabiane mechanicznie, aby zapewnić jednolity wygląd. Poważnie mówiąc, ta gładkość jest kluczowa dla lepszego działania ostrzy podczas wirowania.

Utrzymywanie działania ostrzy w ekstremalnych temperaturach jest również ogromnym wyzwaniem dla inżynierów, tak samo jak w przypadku produktu O.B.T. steam turbine wheel pary wodnego, który przepływa przez turbinę, może być bardzo gorące, więc potrzebne są dobre łopatki, które będą na to odpowiednie. Dlatego inżynierowie badali przez dłuższy czas nowe materiały, które mogą wytrzymać wysokie temperatury. niektóry z nich to ceramiczne, które znacznie lepiej odpierają ciepło niż zwykłe metalowe. Taki rodzaj przewodnictwa może również uczynić łopatki odpornymi na erozję, co pozwala im działać lepiej i trwać dłużej.

Nasza firma może zapewnić usługi dostosowane do indywidualnych potrzeb klientów oraz wykonywać komponenty turbin z szerokiej gamy stopów odpornych na wysokie temperatury zgodnie z wymaganiami klientów. Niezależnie od projektu łopatki turbiny parowej, jej rozmiaru czy wymagań dotyczących wydajności, jesteśmy w stanie je zrealizować dzięki elastycznemu procesowi produkcyjnemu i nowoczesnym technologiom wytwarzania. W ścisłej współpracy z klientami starannie analizujemy ich potrzeby oraz różne scenariusze, z jakimi mogą się spotkać, oferując im profesjonalne wsparcie i porady. Dysponujemy różnorodnymi materiałami oraz możliwościami obróbki, umożliwiającymi spełnienie unikalnych wymagań różnych branż i zastosowań. Dzięki usługom projektowym dostosowanym do indywidualnych potrzeb klientów wspieramy ich w podnoszeniu konkurencyjności na rynku poprzez zwiększenie efektywności i obniżenie kosztów.

Nasza firma może produkować wysoko precyzyjne i stabilne części turbinowe za pomocą odlewnictwa, kuźnictwa oraz obróbki CNC. Odlewnictwo pozwala nam tworzyć elementy o złożonych kształtach, wysokiej sile i długotrwałości. Kuźnictwo nadaje częściom większą trwałość i lepsze właściwości mechaniczne. Technologia CNC, z drugiej strony, gwarantuje wysoką precyzję i spójność każdego elementu, co zmniejsza ryzyko błędów i produkcji produktów nieodpowiadających wymaganiom. Nasz zespół techniczny stale wprowadza najnowsze osiągnięcia technologiczne i poprawy procesów, aby upewnić się, że nasze produkty są zawsze na czele branży pod względem projektowania łopatek turbin parowych. Jesteśmy zdeterminowani spełnieniu potrzeb naszych klientów w zakresie wysoce wydajnych części turbinowych dzięki ciągłemu postępowi technologicznemu.

Nasza firma przestrzega rygorystycznych wytycznych kontroli jakości, aby zapewnić doskonałą wydajność oraz projektowanie łopatek turbin parowych dla każdego komponentu. Kontrola jakości jest przeprowadzana w całym cyklu produkcji — od zakupu surowców po testy gotowego produktu. Przeprowadzamy również regularne audyty jakości oraz korekty procesów, aby zapewnić ciągłe podnoszenie jakości produktów. Naszym celem jest zdobycie zaufania i współpracy klientów poprzez dostarczanie produktów wysokiej jakości oraz stanie się liderem branży.

Nasza kompleksowa oferta obsługi klienta obejmuje konsultacje sprzedawcze, wsparcie techniczne oraz pomoc posprzedażową, aby zapewnić naszym klientom możliwie najlepsze wrażenia. W fazie przedsprzedażowej nasz doświadczony zespół dokładnie analizuje potrzeby klienta i udziela najbardziej odpowiednich sugestii oraz rozwiązań. W zakresie wsparcia technicznego oferujemy pełne doradztwo – od wyboru produktu po instalację i uruchomienie – celem zapewnienia efektywnego użytkowania naszych produktów przez klientów. W przypadku obsługi posprzedażowej opracowaliśmy system usług projektowych dotyczących łopatek turbin parowych, który umożliwia szybkie reagowanie na problemy oraz potrzeby klientów oraz zapewnia szybkie i skuteczne rozwiązania. Chcemy budować długotrwałe relacje z naszymi klientami oraz zdobywać ich zaufanie i uznanie poprzez świadczenie usług wysokiej jakości.