Turbină compressoare este o parte crucială a sistemului nostru de răcire domestică. Acesta este un mic obiect rotitor care se rotește foarte repede și creează presiune. Această presiune este ceea ce forțează aerul rece să intre în casa ta. Conditia ta ar avea dificultăți să te țină pe mine răcoros dacă turbină compressoare nu ar fi acolo. Este ca un super ero folosind puterile sale în sistemul tau de răcire să lupte alături de tine pentru a te menține rece oricare zi caldă din an<()>

Dacă doriți ca compressorul de aer să funcționeze bine, atunci poate fi de ajutor dacă un rotor este actualizat în acest sens. Un rotor mai bun poate produce o presiune de aer mai mare, așa că aceasta răcirea casei sau biroului dvs. mai repede. Un spațiu de trai mai rece se simte minunat, cu siguranță! De asemenea, climatizatorul dvs. va funcționa mult mai eficient, economisindu-se bani pe încălzire și răcire. E ca și cum ați avea acest nou superheroie fantastic și ei pot face chiar mai mult!

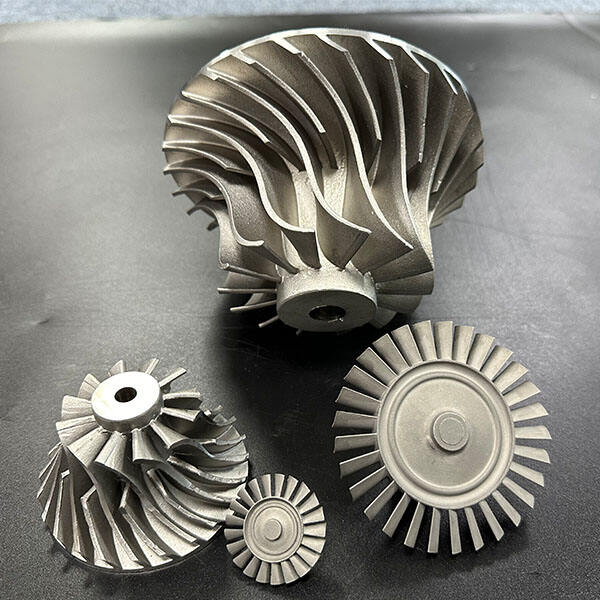

Rotorul compressorului este destul de mic, dar nu vă lăsați păcălit de dimensiunea lui; acesta face tot un loc de muncă foarte mare. Este compus din câteva componente esențiale: lame, carcasă și axă. Lamele sunt formate ca un ventilator și sunt montate una câte una la carcasă. Pe măsură ce carcasă și axă se rotesc, fac lamele să se rotească foarte repede, ceea ce duce la crearea presiunii de aer. Designul rotorului compressorului joacă un rol semnificativ în majoritatea cazurilor, în creșterea potențialului presiunii de aer. Astfel, rotorul poate să facă treaba sa bine.

Îmbunătățirea turbinelor compresorului dvs. deschide calea spre multe avantaje minunate, precum și alte beneficii. Nu doar că promovează eficiența în sistemul HVAC, dar asigură, de asemenea, că economisiți fiecare lună pe cheltuielile de energie. Al doilea punct: o turbină nouă poate săraci mai repede casa dvs. Acest lucru vă va face să transpirați mult mai puțin, în special cu soarele de vară. În sfârșit, o turbină nouă a compresorului permite, de asemenea, aerificatorului să aibă o viață utilă mai lungă. Astfel, puteți pur și simplu să o lăsați să meargă și să uitați să o înlocuiți. Este cam ca și cum ați avea un supererou care nu doar că performă mai bine, dar și care ia mai mult timp până când se retrage!

Dacă constatați că instalatia voastră HVAC nu funcționează cum ar trebui, o cauză posibilă ar putea fi legată de impalierul compressorului. Lame rupte: Impresorii de lemn folosesc un volan pentru a acumula energie cinetică și apoi lovesc lemnul cu lamele de pe celălalt său capăt. Dacă întâmpinați vreuna dintre aceste probleme de încălzire, sunați un tehnician HVAC profesional pentru ajutor. Aceștia au cunoștințele necesare și sunt abili să identifice exact unde se află problema voastră și să înlocuiască impalierul defect al compressorului atunci când este nevoie. Este bine să țineți minte că chiar și eroul nostru superheroic are nevoie uneori de menținere pentru a rămâne într-o formă fizică de top.

Compania noastră poate oferi servicii personalizate și este capabilă să realizeze componente pentru turbine dintr-o gamă variată de aliaje rezistente la temperaturi ridicate, în conformitate cu cerințele clienților. Indiferent de tipul de rotor de compresor, dimensiune sau cerință de performanță, putem îndeplini orice cerință prin intermediul procesului nostru flexibil de producție și al tehnologiilor de ultimă generație utilizate în proces. Colaborăm strâns cu clienții pentru a înțelege nevoile lor, precum și diversele scenarii cu care se pot confrunta, oferindu-le asistență profesională și recomandări specializate. Dispunem de o varietate de materiale și capacități de prelucrare pentru a satisface cerințele specifice ale diferitelor industrii și aplicații. Ajutăm clienții să-și consolideze competitivitatea pe piață, oferindu-le servicii concepute personalizat, care îmbunătățesc eficiența și reduc costurile.

Suntem în măsură să creăm componente pentru turbine cu o precizie ridicată și o calitate consistentă prin intermediul mașinării CNC, fundirea și forjarea. Fundirea ne permite să realizăm piese cu forme complexe, o putere mare și o durabilitate îndelungată. Forjarea poate oferi pieselor o rezistență mai mare și proprietăți mecanice superioare. Tehnologia rotorului compresorului CNC, pe de altă parte, asigură cea mai mare precizie și exactitate a fiecărui element, minimizând erorile și asigurând că produsul este la un standard înalt. Echipa noastră tehnică, extrem de calificată, dezvoltă continuu progrese tehnologice și optimizări ale proceselor pentru a menține produsele noastre la cel mai înalt nivel tehnologic din industrie. Angajamentul nostru este să ne conformăm nevoilor clienților noștri pentru componente cu performanță ridicată prin dezvoltarea continuă a tehnologiei.

Serviciul nostru complet de asistență clienți include consultanță pre-vânzare, asistență tehnică și servicii post-vânzare, pentru a asigura clienților cea mai plăcută experiență. Echipa noastră de experți va evalua nevoile clienților și le va oferi sugestii adecvate privind produsele, precum și soluții corespunzătoare. Ofertăm asistență tehnică începând cu selecția produselor, până la instalare și punerea în funcțiune. Acest lucru asigură faptul că clienții noștri pot beneficia de produsele noastre fără probleme. Pentru asistența post-vânzare, am dezvoltat un sistem de servicii eficient, capabil să răspundă rapid la problemele și nevoile clienților, oferindu-le soluții eficiente privind rotorul compresorului și alte componente. Scopul nostru este de a construi relații pe termen lung și de a câștiga încrederea și satisfacția clienților prin furnizarea unui serviciu de înaltă calitate.

Compania noastră respectă cu strictețe directivele de control al calității pentru a asigura o performanță excelentă și un rotor de compresor de înaltă calitate pentru fiecare componentă. Controlul calității este efectuat pe întreaga durată a procesului de producție, începând cu achiziționarea materiilor prime până la testarea produsului finit. De asemenea, efectuăm periodic audite și ajustări ale calității pentru a asigura o îmbunătățire constantă a calității produselor. Scopul nostru este de a câștiga încrederea și cooperarea clienților noștri oferind produse de înaltă calitate și de a deveni un lider în domeniul nostru de activitate.