The gas turbine engine blade is not just any airplane part, it is one of the most critical parts. The airplane uses this special blade to help it flying high in the sky overcomes air. In this series, we will take a look at the various components that make up an individual gas turbine engine blade-the materials utilized in its construction and exactly how it goes about creating power; as well as some ways to maintain (and repair) them so they may function properly.

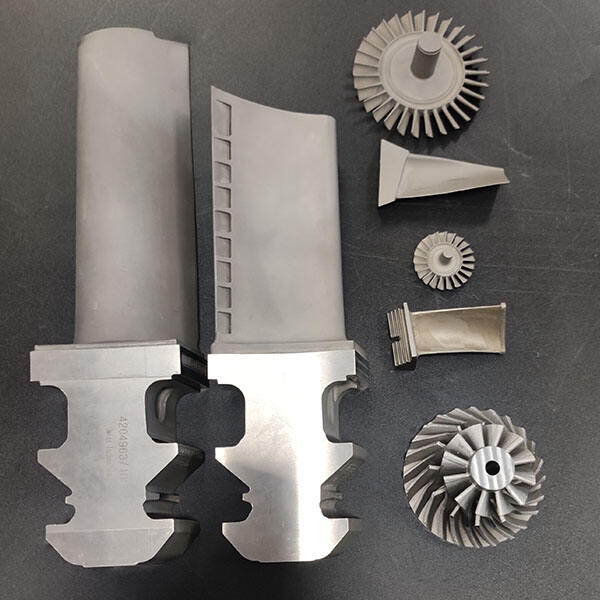

The blade of a gas turbine engine consists of several components that enable the plane to fly. This part is called the airfoil. The curved part of the blade that looks like a wing is an airfoil. This form is important because it enables the airplane to lift off and stay in flight. That plane was not going to fly worth a damn without a decent airfoil. Another Essential Part Is The Root The root is the part of a blade that attaches to an engine. The metal is very stout and serves to keep the blade firmly in place during flight which makes it able to bear the force of flight. There is also the shank, which attaches the airfoil to a root. These parts all play a role for the aircraft to fly optimally.

Gas turbine engine blades, such as these made by honeywell with the help of 3D printing technology are one area where engineers strive for still better performance. They achieve that by changing the blade design. A fun thing about the blade is when you add small bumps to it. Also, these small bumps help to create a little air(currents) going by the blade (which makes it cooler). This is significant because a cooler blade can function better. Another solution that engineers implement, to improve the architecture of blade is by making it more aerodynamic. A blade that is aerodynamically contoured allows air to flow smoothly over it. And besides the ambient airflow, you want things to be as smooth around your moving blade making it possible for that airfoil to work well and have an efficient airplane.

The creation of gas turbine engine blades depends on certain specialized materials chosen nocely for the nice_coordinate. These materials must be able to survive the high temeratures and pressures that are present when flying. On the other hand, they have to be very light not too heavy for an airplane. Titanium, nickle and ceramic are the three fellow materials that widely used in it. While bare steel can be pretty costly, it is absolutely critical to ensure the blade will work as intended and safely.

The gas turbine engine blades turn burning fuel's energy into kinetic or movement energy which is then used to power the plane through space, and these are the parts of what makes aircrafts fly. It has to be optimised form of airfoil, specifically designed in order to grab as much energy from the burning fuel s hot gases as only it is possible. The hot gases go over the curved shape of the blade as it goes by inside changing its direction or angle so there is an imbalance force. The interaction results in a pressure differential between the top and bottom of an airfoil, thus generating lift. Lift is what gets the airplane up into the air and allows it to move forward.

To function at high levels, gas turbine engine blades require routine care and maintenance. A great place to start is keeping a close eye on those blades for signs of wear, damage or misalignment. And if any part of a blade is found to be crash it in imperative that you fast fix or as soon change on the fly. Cleaning the BladesRegularly cleaning the blades is a good way to keep them working normally. This will stop the accumulation of dirt, dust or debris on the surface which can affect its performance and efficiency.

Our company follows strict quality control standards to guarantee the best performance and dependability of each component The entire gas turbine engine blade is monitored for quality starting from the purchase of raw materials all the way to the final test of the final product To ensure that the quality of our products is continually improved we regularly conduct audits and adjustments Our aim is to earn the trust and continue to work with of our customers by providing top-quality products and becoming an industry leader

Our company provides gas turbine engine blade and can make turbine components in many different high temperature alloys according to the requirements of customers. Whatever the size, shape, or performance requirement, we are able to meet it using our flexible production processes as well as our advanced processes. We collaborate closely with our customers to comprehend their needs and applications scenarios and then give them professional assistance and suggestions. We have a broad range of processing and materials to meet the unique requirements of different sectors and application. We help our clients improve their competitiveness in the marketplace by offering custom-designed services that improve performance and reduce costs.

We can create turbine parts with high precision and consistency through gas turbine engine blade, machining and forging processes. Casting allows us to create parts with intricate designs, strong and durability. Forging gives parts a more durable and superior mechanical property. CNC machining technology, on the contrary, provides the highest precision and accuracy of every part, which reduces the chance of the chance of errors and producing substandard products. Our experienced technical team is always working on technological innovations and process improvements in order to ensure that our products remain at the leading edge of industry technology. We are committed to meeting the demands of our clients for high-performance parts by constantly advancing technology continuously.

Our customer support is comprehensive and includesgas turbine engine blade, technical support, and after-sales services to ensure that our customers get the best experience possible. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support starting with the selection of products to installation and commissioning. This ensures that our clients are able to use our products without any issues. We have a well-developed after-sales process that allows us to swiftly respond to issues and needs of customers, and to provide effective and prompt solutions. We are determined to develop long-term relationships with our clients and gain their trust and respect by offering high-quality services.