The steam turbine is a very powerful machine, which gives ample pressure to rotate blades with either in an accurate wrapper and proceeds generator. Have ever thought of how the configuration of shape and design the nozzle does in the steam turbine helps by offering maximum impulse?.

Very important: A turbine nozzle in a steam turbine guides a stream to go blades. The nozzles help the steam to enter with the proper angle and speed, which needs to be followed to extract energy and as much as possible from the blades.

These designers don't want to do lets of great efforts in optimizing the output but rather become more innovative at designing O.B.T Turbine accessories to ensure accuracy at the engineering levels and yet be cheap. For example, they would be able to visualize how such thermal waves propagate through their spacetime classically curved; For example using steam (or other fluids) as an ideal fluid and optimize the shape of nozzles and flow angles for a more efficient power generation process.

And knowing the working of a to know the steam turbine principle design basics how they are mechanically arranged to nozzle so the following: How Steam Turbines work does Steam work? Steam Turbine The enters into stator to push more over way turned by the blade. This driveshaft is connected with generator which produces electricity when its blades revolve in the wind.

The efficiency of a power plant depends on how well they make steam perform to extract energy from it. Hence the nozzle plays an essential role to ensure everything functions quickly. An example of this is the low-temperature steam expanders designs nozzles. So that high-speed passing through them allows simmer. This means that it is tangential to the steam which explains how such blades are able to capture more energy from mass incoming at greater velocity.

There are several types of O.B.T steam turbine nozzles. So, we choose one type based on the performance needed from that type in an application. Though nozzle type and size are different with this principle, each nozzle should be designed such that proper streamline flow of the steam can take place to reduce the pressure drop pressure due to resistance.

Recent trends of sustainable and eco-friendly solutions have also instroduced the same to modern engineering as well. In power generation steam turbines are essential and their efficiency plays an important role for both output energy. As well environment charges footprint of the plant

The designers apply sophisticated techniques for the design of this steam turbine nozzle concept that makes it more sustainable. One is an advanced procedure called Computational Fluid Dynamics (CFD), utilizing complex mathematical models to simulate fluid activity such as steam Turbine Wheel. CFD analysis will guide the designers to how steam flows through that fuel nozzle gas turbine and they can change shape of that nozzle for enhanced efficiency.

Steam turbine nozzle design is difficult, and there are many ways to improve performance. Nozzle design is the one area that varies significantly in blade shape either to tap more energy out of steam or for toughness and robustness.

The second feature of Turbine Blade design is reaction design and it not only guide the flow but u also have to contributed in other direction which means you must increase its kinetic energy. The reaction design can also significantly improve a turbine efficiency as maxing out how much energy is transferred on that steam.

The less terrible it is burning fuel, the better it is at making electric power from steam. Steam turbine nozzles: Engineers always try to make processes involving steam turbines more efficient. They can, then, go ahead and design the nozzle to include those flames or position them at an optimal angle by analyzing how steam flows. In other words it allows steam an easier path of escape from its exhaust Thanks to this paper, it can be understood how important is the design of gas gas turbine fuel nozzle in a steam turbine when considered for power generation.

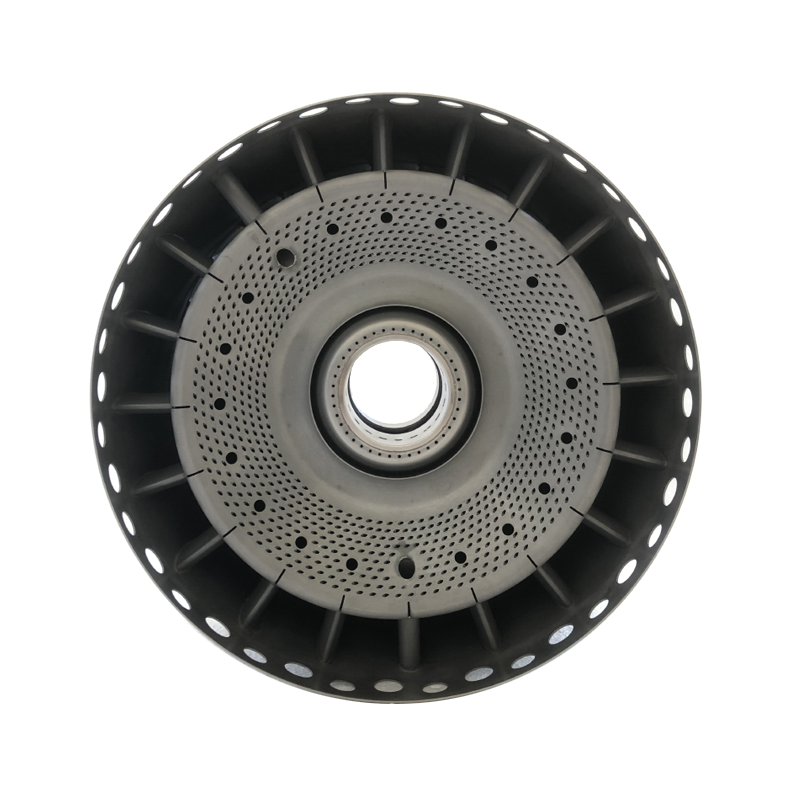

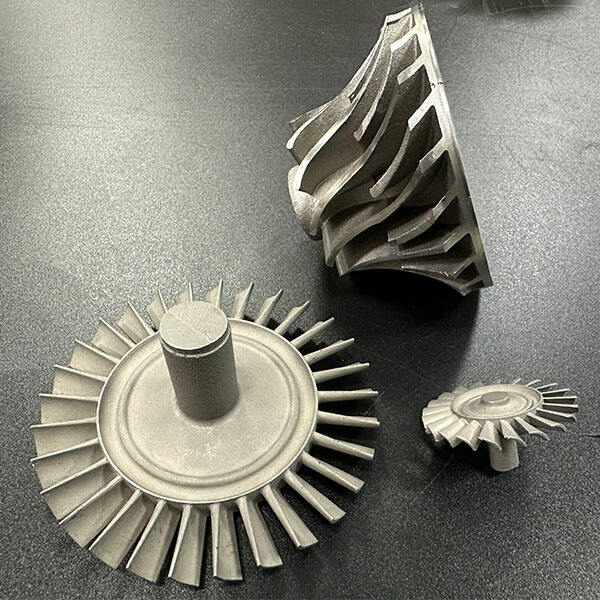

Our company is able produce highly accurate and consistent turbine parts by casting, forging, and CNC machining processes. The casting process allows us to produce parts with intricate shapes and strong durability, while the forging process gives the parts better Steam turbine nozzle design and longer lasting. CNC machining technology, on the contrary, guarantees consistent and high-quality of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have a highly skilled technical team that constantly carries out technological innovations and process improvement to make sure that our products stay in the forefront of industry in terms of technological. We are committed to meeting the requirements of our customers for components that are high-performance by developing technology continually.

We offer a comprehensive customer service which includes pre-sales advice as well as technical support and after-sales support, in order to ensure our customers get the best experience. In the Steam turbine nozzle design the team's professional staff will understand the customer's needs in detail and provide the most appropriate suggestions for products and solutions. We provide technical support starting with the selection of products, through installing and commissioning. This guarantees that our clients are able to use our products without any problems. We have an established after-sales process that allows us to quickly respond to customer concerns and issues and to offer effective and prompt solutions. We want to create long-lasting relationships with our customers and gain their trust and satisfaction through offering high-quality services.

Our company is committed to strict quality control standards to guarantee the best performance and reliability of every component Every step of the production process is controlled for quality starting from the purchase of raw materials all the way to the final test of the product We also carry out regular quality audits as well as adjustments to ensure constant improvements in product quality Our goal is to win the trust and continue to work with of our clients by offering top quality products and to become an Steam turbine nozzle design

Our company provides specific services that is able to manufacture turbine parts from an array of high-temperature metals to meet customer needs. If it's a particular shape, size or performance requirement, we are able to meet it using our flexible production process and the latest process technology. We stay in close contact with our clients to comprehend their individual requirements and scenarios, and provide them with expert technical guidance and solutions. We have a broad range of materials and processing capabilities to meet the unique needs of various industries and applications. Our clients can improve their Steam turbine nozzle design by providing specific services that maximize performance and reduce costs.