Flygplansmotorbränslestrålar

Högpresterande Bränslestrålar för Jetmotorer

Våra avancerade bränslestråletippar är utformade för precisionsbränsleatomisering, vilket säkerställer optimal förgasningseffektivitet inom jetmotorer. Dessa komponenter spelar en kritisk roll i motorprestationerna och påverkar direkt bränslekvaliteten och utsläppen.

Vi specialiserar oss på nästa generations trippelkanalsbrännmynningar, vilka stöder fasvis bränning och teknik för tunn blandad virvelflamma. Detta möjliggör lägre utsläpp, bättre bränsleeffektivitet och stabil drift under en bred spektrum av förhållanden.

Nyckelfunktioner:

- Trippelkanalsflödesdesign för fasvis bränning

- Tunn blandad högvirvelflammusteknik

- Noggrann bränsleatomisering

- Minska utsläppen och förbättra brännstabilitet

- Anpassningsbara flödeskalkyleringsalternativ är tillgängliga

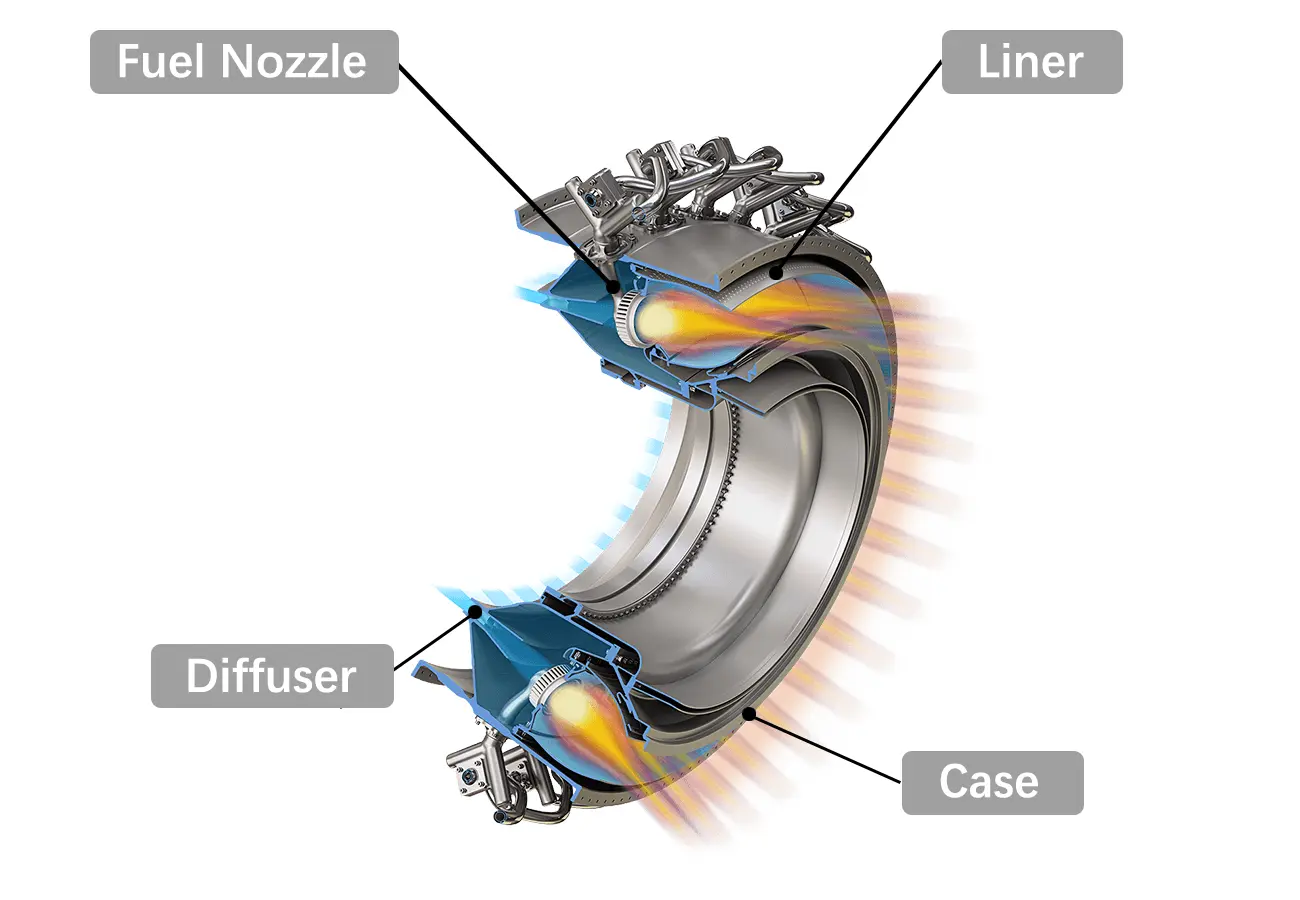

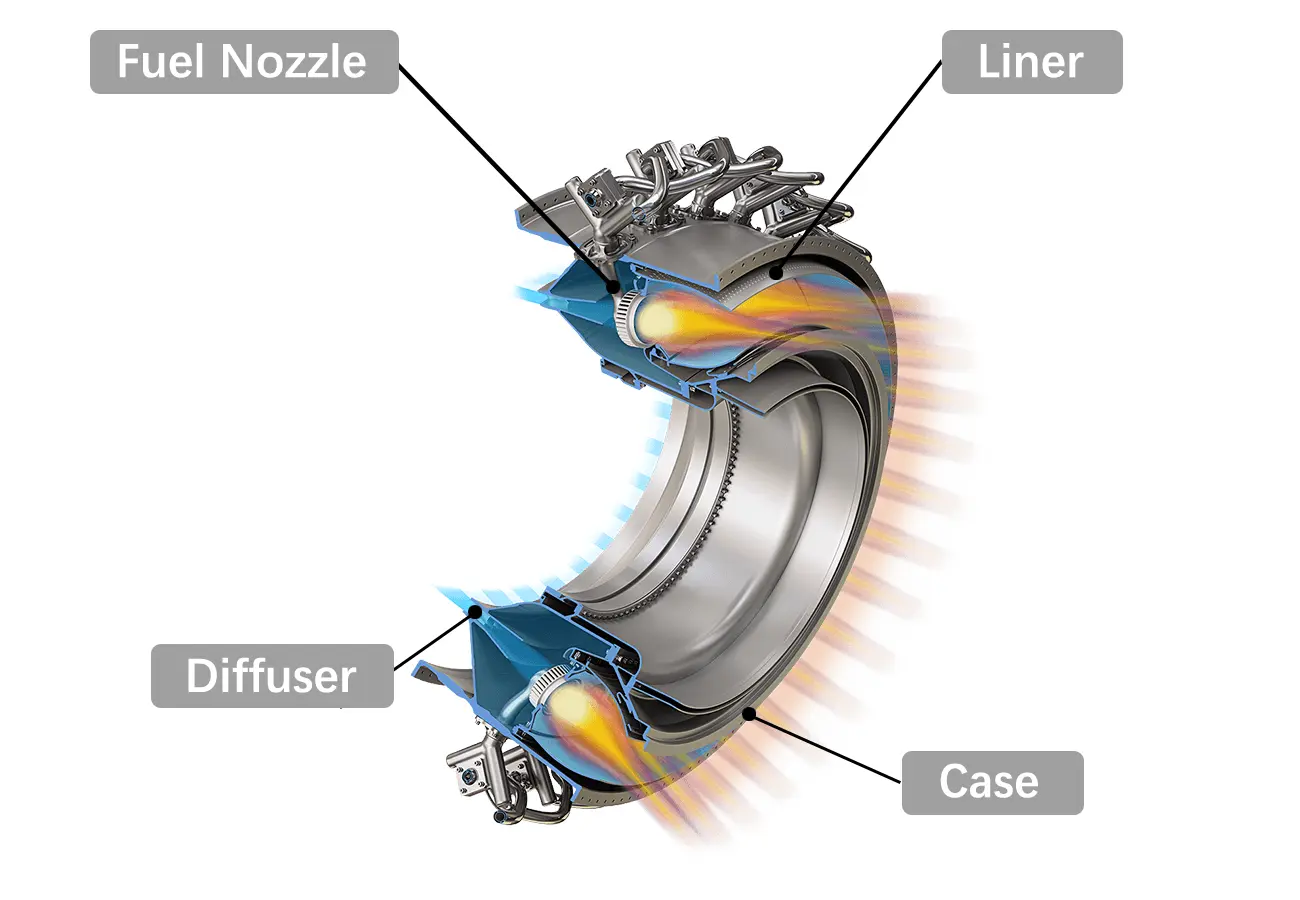

Lösningar för brännkammernkomponenter

Vi erbjuder en komplett linje av noggrant konstruerade delar för flygmotorers brännkammare, byggda för att fungera under extrem värme och tryck.

-

Brännmynningsmontering

Som det centrala komponenten i brännsystemet tillverkas våra brännmynningar med strinta toleranser och går igenom strikta flödestester. De säkerställer stabil, effektiv bränning och pålitlig motoroperation.

-

Diffusör

Våra diffuser är utformade för att försena inkommande luft från kompressorn samtidigt som tryggleendet minimeras. Många modeller har integrerade Outlet Guide Vanes (OGVs) och är konstruerade av värmebeständiga superlegeringar för hållbarhet och lätthet att svetsa.

-

Brännkammervägg

I brännkammerväggen sker den faktiska förgasningen. Våra väggar är utformade för att optimera luftflöde och kyla, vilket maximera förgasningseffektiviteten med minimal användning av kyl Luft, vilket låter mer syre delta i förgasningen.

-

Housning

Motordskor ger den strukturella skalen runt förgasningsområdet. Byggda för styrka och säkerhet i sigillering, garanterar våra drskor långsiktig tillförlitlighet även i de harschaste miljöerna.

Avancerade tillverkningsmöjligheter

Vi tillämpar moderna processer för att leverera de mest krävande bränslebusskomponenterna:

-

Gaskran & Ventilskiva

Hög cirkularitet och extremt stramma dimensionella kontroller för kritisk reglering av bränsleflöde.

-

Huvudörificemaskinering

Mikrobohrning med burrfritt färdigbearbetning och utan skador på bakytan. Taperade design är tillgängliga.

-

Tillverkning av bränslestångskärna

Komplexa delgeometrier stöds av avancerad fixeringsteknik och mikronnivås noga.

-

Svirlkärntillverkning

Tillverkats av svårt att bearbeta material med extremt hög dimensionsnoggrannhet, vanligen färdigbehandlad med högprecisionslödning.

-

Lödningsprocesser

Flercyklisk vakuumlödning med en mängd olika fyllningslegeringar. Alla led undergår strikta kvalitetsinspektioner.

-

Flödeskalfyrering

Flerstegs flödeskalfyrering säkerställer precist bränsleleverans, särskilt efter veldning och sammansättning, för att garantera konstant prestanda.