Steam turbines are remarkable devices that help in the transfer of heat saturated steam into mechanical energy which we can then supply to a variety of equipment like generators. The steam that goes into the turbine is very pressurized. Travelling through the turbine a pressure drop (volume expansion) also occurs. The expansion of this steam creates kinetic energy which propels the turbine blades. Big-P or big-r, the nozzles are control valve obviously critical to release of steam precisely and type.

A steam turbine operation simply depends on heating boiled water into high-pressure steam that is made to set turbines blades in motion. This produces the steam, which is in turn generated by heating water with raw materials mounted external of it such as coal or natural gas The nozzle discharges steam at high pressure and velocity, as the section along its length is gradually diminished in size so that when passing through it will be directed to a smaller area where it suffers an acceleration exerted by this restriction. This increased energy is subsequently moved to the turbine blades which then spins a generator as a source of supplying electricity. The performance of the steam turbine has a direct relationship with its efficiency and hence capacity, is dependent on nozzle which transforms the energy provided by high pressure superheated steam to kinetic energy.

What are the nozzles function in steam turbines: The proper operation of this type of turbine is carried out by conducting a flow and direction for the expansion-steam to shift between weaves if blades. Nozzle is custom designed for a specific steam turbine to take into account the operational conditions of the said machine, characteristics and properties of steam used as working fluid in that application and targeted power output from this particular kind of equipment. The nozzles need to endure high temperatures, operate under high pressures and maintain precise geometries in order for everything else in the system to work at an optimum efficiency level.

Next to this the nozzle design is a critical for performance of steam turbine. The nozzles are designed to control the speed and flow of steam, in an attempt maximize efficiency within rotation of turbine blades. The size and design of the nozzle used are crucial to controlling flow steam within your turbine. Ineffective nozzle designs can in turn lower turbine efficiency, increase blade wear and operational costs. Poor nozzle design is less expensive (to change one or two nozzles when unsuccessful), but riskier in terms of rapid steam expansion leading to potential for turbulence causing blade erosion, or inefficient conversionance of the energy contained within the gaseous water.

Steam turbines depend on nozzles to bring up their efficiency quite easily. Calculating the potential steam energy to kinetic energy released by a given nozzle is an important piece of calculating your kilowatts - or just how much useful work can be derived from what you've got. Strict dimensions of the nozzle are maintained which allows steam to be released at a specific point, angle and velocity. A properly-engineered nozzle improves power transfer from steam to turbine and then ultimately the generator, utilizing it as efficiently as possible.

To sum it up, nozzles play a major key role in the functioning of steam turbines as they control how and where steam flows when passing through the turbine blades. The better the conversion of steam energy into kinetic energy in a nozzle, the higher the efficiency and performance of a steam turbine. Ultimately, the steam passing through nose must be released as a function of time at an angle and velocity that converts as much energy from heat (steam) to mechanical power in turbine/generator. Nozzles are important components in steam turbines and this is a fact that cannot be gainsaid since they help ensure the efficiency of these natural ways to Export Company.

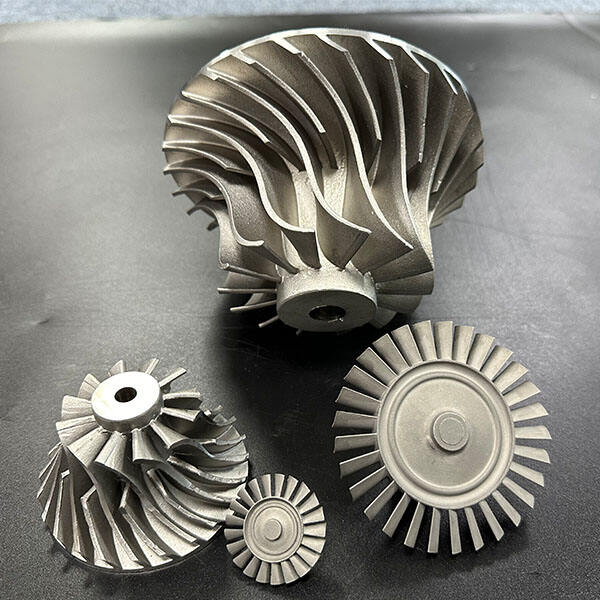

Our company has the ability to create highly precise and reliable turbine parts through casting function of nozzle in steam turbine, and CNC machining processes. Casting allows us create components with complex designs, strong and long-lasting. Forging provides parts with a better mechanical quality and longer durability. CNC machining, on the contrary offers high precision and consistency for every component. This reduces errors and inferior products. Our technical staff is constantly developing technological advancements and process improvements to ensure our products are at the forefront of industry technology. We're committed to meeting our customers' demands for high-performance turbine components by continual technological advancement.

Our company is committed to strict quality control guidelines to ensure the highest quality and reliability of every component Quality control is conducted throughout the entire manufacturing process from the purchase of function of nozzle in steam turbine to the test of the finished product We also perform regular quality audits and improvements to ensure continuous improvement in the quality of our products Our aim is to earn the trust and long-term cooperation of our clients by offering quality products that are of the highest standard and to be a leader in the industry

Our complete customer service package includes pre-sales consultation technical support and after-sales assistance to ensure our customers have the best possible experience When it comes to the pre-sales phase our experienced team will understand the customer's needs in detail and provide the most suitable suggestions and solutions In terms of technical support we offer full guidance from product selection until installation and commissioning to ensure that our customers use our products efficiently When it comes to after-sales service we have developed an function of nozzle in steam turbine service system that can respond swiftly to customer issues as well as needs and provide quick and effective solutions We want to create long-lasting relationships with our customers and gain their trust and appreciation by offering high-quality services

Our company provides function of nozzle in steam turbine, and we is able to manufacture turbine parts from many high-temperature aluminum alloys in order to satisfy the demands of customers. Our flexible production flow and advanced technology for processing and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet any need. We work closely with customers to fully comprehend their requirements and applications scenarios and provide them with expert assistance and suggestions. We have a broad range of materials and processing capabilities to meet the special demands of various industries and applications. Our clients can improve their competitiveness on the market by offering customized services that optimize performance and reduce cost.