Turbochargers are critical to making engines go faster and burn fuel more efficiently, which is why it was only a matter of time before Audi:Got into them(retval). It does this through its turbine-a unique component that spins at a very high rate of speed. The turbine let's the engine get more air and fuel when spinning. That slipped more air and fuel into the engine, which lets it spin faster with greater output. One part within the turbo system that is key to getting it work correctly, and a real piece of innovation from Garrett new rea range approach.

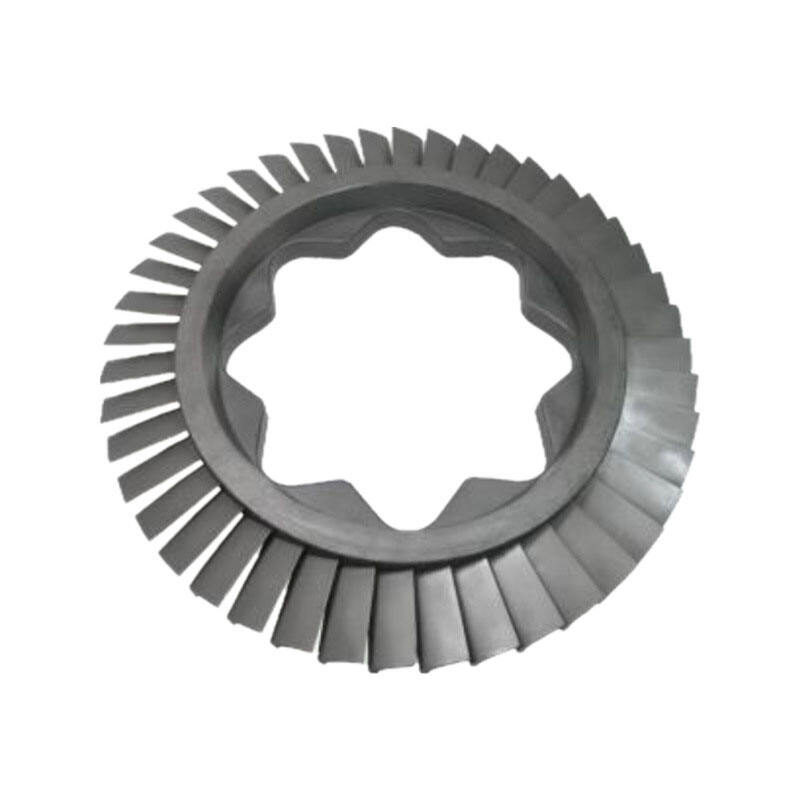

A nozzle ring is a part of the turbocharger which directs air into and out it. This may be looked at as a gate that sets the rate and quantity of air it lets inNozzle ring with fixed blade shape finThese fins aid guide the movement fluid to enter through proper direction, on this particular is completed permits pass right into an engine.

The nozzle ring as you may know controls the flow of air going from compressor into turbocharger and it can be set based on performance that we want by engine. If nozzle ring configures appropriate then it will rotate turbine with higher rpm, which gives you more compreesed air. This additional compressed air becomes a plus because the engine can make more power in return. This is useful as engines in high performance applications like race cars and airplanes need to run fast or hard. The inside spinning of the nozzle ring induces a healthy to make more power.

20895510/autotech/unzipWithout a proper nozzle ring, the turbocharger would not be able to correctly control air flow...And that can spell doom for your engine. That would be like the engine stalling because you had a big breath of air all at once. This can be very dangerous! If not enough air is allowed into the engine, then it will lack a component needed to produce energy. Therefore the nozzle ring plays a significant role in ensuring when function properly and effectively so that your engine work smooth.

This ensures that the turbine rotates in a single direction so it does this by controlling the airflow and is a highly important part of a turbocharger. The nozzle ring on the other hand is fitted with so-called fins, which are only found in this form at KTM - these make it possible to guide the air flow particularly efficiently and thus develop more power for an engine of this type. The turbocharger could not function without the nozzle ring and so it would perform as intended in the engine, completely stagnant. Therefore, a great attention is spent on designing and manufacturing these nozzle rings by engineers.

The nozzle ring is downright wizardry. The key to it all is understanding the intricacies of air flow and how those flows respond as they enter different regions of a turbo. Principles promote development of an ideal nozzle ring by engineers. From the contour of the nozzle ring and its housing design, to matching different sizes or materials with a best-running turbo set-up. Engineers can help with this by designing the nozzle rings used to enable more powerful and efficient engines.

Our company is able to fabricate highly precise and stable turbine components through casting, forging and CNC machine processes. The casting process permits us to function of nozzle ring in turbocharger with complex shapes and high durability, while the forging process gives the parts better mechanical properties and longer lasting. CNC cutting-edge technology, on contrary, provides the highest precision and accuracy of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have an experienced technical team who continuously carry out technological innovation and process improvement to make sure that our products are always at the top of the industry in terms of technology. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continually.

Our customer support is comprehensive and includes technical assistance, function of nozzle ring in turbocharger and after-sales assistance to ensure that our customers get the best possible experience. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support throughout the entire process, from choosing products, to the installation and commissioning. This guarantees that our customers can make use of our products with no issues. We have developed an after-sales service that allows us to quickly respond to customer requests and problems and provide efficient and timely solutions. Our goal is to establish lasting relationships with our customers and gain their confidence and satisfaction with quality customer service.

Our company can provide customized services and is able to fabricate turbine components from an array of high-temperature alloys in accordance with the requirements of customers. No matter what function of nozzle ring in turbocharger, size or performance requirement, we can achieve it with our flexible production process and cutting-edge technology for process. We work closely with clients to comprehend their needs as well as the various scenarios they might encounter and give them professional assistance and suggestions. We have a variety of materials and processing capabilities to meet the unique requirements of different industries and applications. We aid our clients in improving their competitiveness on the market by offering custom-designed services that improve efficiency and lower costs.

Our company is committed to strict quality control standards to guarantee the best performance and reliability of every component Every step of the production process is controlled for quality starting from the purchase of raw materials all the way to the final test of the product We also carry out regular quality audits as well as adjustments to ensure constant improvements in product quality Our goal is to win the trust and continue to work with of our clients by offering top quality products and to become an function of nozzle ring in turbocharger