Hi there! We will understand everything about gas turbine blades today. Those blades are extremely significant and they capture energy that essentially provides us with power in our day-to-day living. Sounds cool, right? So, without further ado — here is how these blades work and what makes them so unique!

The gas turbine blades are crucial components needed to produce energy in a machine named as the gas turbine The designers of these blades are also the engineers who want to improve them so that they can be implemented in an even better way. That is to say, it wants the blades and create more energy/source at a faster time. These fast-spinning blades can be used to generate electricity that lights up our homes and schools, and many more other places.

We want the blades to be better and we are experimenting with new materials as well as shapes for them={({ They are looking for materials which are strong but very lightweight. This is useful due to the fact that lighter blades are able to rotate faster, ignition of more electricity. Engineers also ponder casts of the designers and possible shapes that could make their blades work better in air. Engineers can greatly affect the performance of gas turbine blades by refining materials and shape.

Airflow is very crucial when talking about gas turbine blades. Aerodynamics, we might say “Clean air should not make turbulence along the blades as they turn. Turbulence is created if the air does not flow well. Turbulence is when the airflow is not flowing in a single direction, or it may falter repeatedly at some points; this behaviour will greatly hamper the spinning process of blades. If those blades cannot spin freely, they are unable to generate energy as well. This is why engineers spend a lot of time worrying about where the air goes as it moves past a blade. Assuming knowledge in aerodynamics, they can engineer the blades to be less turbulent and thus more efficient.

Material of gas turbine blades is a big deal These materials must be strong and light so that the harsh conditions inside a gas turbine can either resist or fight these forces. > One of the popular materials that engineers often use because is very strong called inconel. Inconel, which is a special metal that can handle really high temperatures. This is a good thing as gas turbines can be red hot when running and the blades need to remain strong. Ceramic Ceramic is an other strong interconnected molecule form, where engineers often resort to as a material. Ceramic is good because it could be very sturdy and may face up to so much of damage Choosing the right materials ensures that your blades perform and endure.

They are not easy to make, and they have to be made flawlessly because of how turbine blades work. Any little error in how blades are made might lead to chaos down the line. The engineers have some special ways to ensure that the paddles are perfect. I think one of the cool ways they get this done is via "3D printing. This technology enables them to print a 3d model of the blade from a computer. This allows them to ensure that the blade is exactly as it should be for everything to go smoothly.

Engineers also utilize computers to model and test alternate blade designs. This is called computer simulation. Using computer models, researchers can simulate designs without the need to build them first. It's very helpful, since it saves you a lot of time and money. Quick and Easy to Try Out Many Different IdeasEngineers can ping-pong many different ideas swiftly. They can use these simulations to optimize the blades as much as possible. By doing this, they are able to generate more power with the same amount of fuel and that is a big win for the enveronment as well as saving people money on energy bills.

Our company provides gas turbine blade design and can make turbine components in many different high temperature alloys according to the requirements of customers. Whatever the size, shape, or performance requirement, we are able to meet it using our flexible production processes as well as our advanced processes. We collaborate closely with our customers to comprehend their needs and applications scenarios and then give them professional assistance and suggestions. We have a broad range of processing and materials to meet the unique requirements of different sectors and application. We help our clients improve their competitiveness in the marketplace by offering custom-designed services that improve performance and reduce costs.

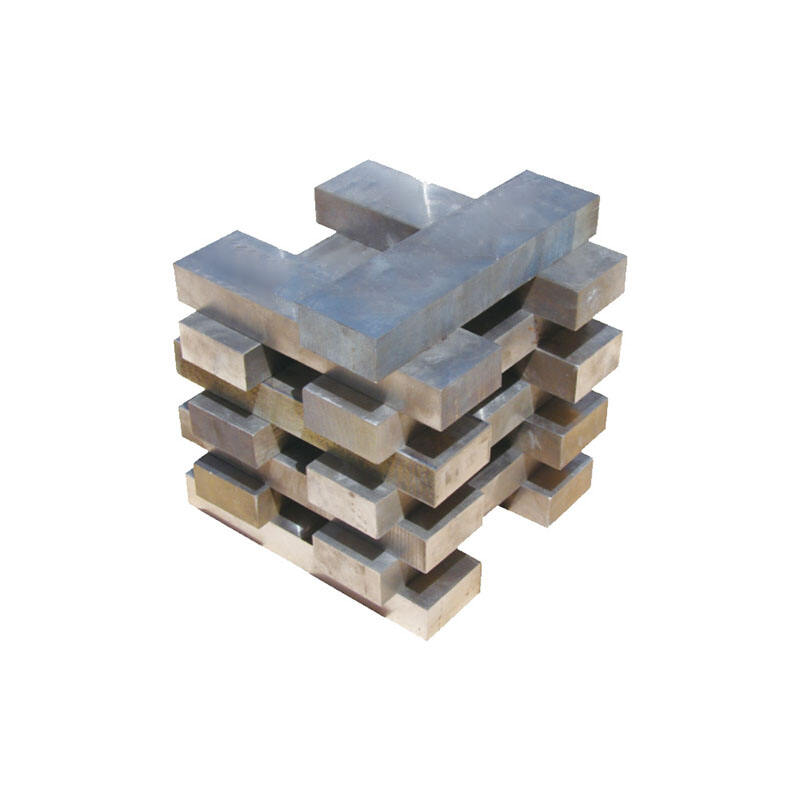

We are able of producing turbine components with high accuracy and consistency through CNC machining, casting and forging processes. The casting process permits us to create parts with intricate shapes and strong strength, while the process of forging provides parts higher mechanical properties and longer lasting. CNC machining, on the contrary it provides superior precision and consistent quality for every part. This reduces errors and lower quality products. Our skilled technical team is always working on technological innovations and process optimizations in order to gas turbine blade design that our products remain at cutting-edge of technology in the industry. Our goal is to satisfy the needs of our customers for high-performance parts by constantly advancing technology continuously.

We adhere to the strictest guidelines for quality control to ensure the gas turbine blade design and reliability each component. Every step of the production process is monitored for quality starting from the purchase of raw materials all the way to the final test of the product. To ensure that the quality of our products are continuously improved, we conduct regular audits and improvement. We want to win the trust of our customers and their long-term cooperation by providing high-quality products.

Our comprehensive customer service includes pre-sales consulting technical support and after-sales services to ensure that customers enjoy the most enjoyable experience Our expert team will assess the needs of customers and offer appropriate product suggestions and solutions We provide technical support starting with the selection of products through installation and commissioning This ensures that our customers are able to enjoy our products without issues For after-sales support we have developed an efficient service system that can respond swiftly to customer issues as well as needs and provide gas turbine blade design and efficient solutions Our goal is to create long-term relationships and gain customers trust and their satisfaction by providing superior customer service