A turbine is a machine that generates electricity by rotating trip veins. Did you ever think how are they work? Well, it’s quite interesting! The blades spin rapidly when water or steam impinges on them. This moment of turning motion will create energy and can be used to drive any appliances as well and we light our houses too.

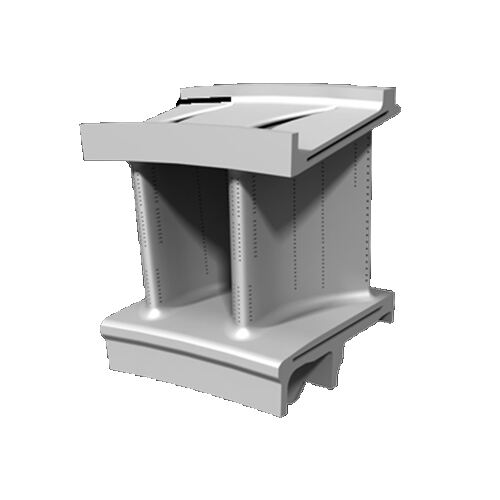

Guide vane is an important constituent of turbines. These particular guide vanes are curved blades for channeling the flow of water or steam moving through a turbine. Perhaps deceptively simple, these guide vanes are critical to ensuring turbines work in an optimal way. They are of great importance or else the turbine will only be operated and it might not perform well.

Vaned guide system enhances the performance of turbines. The water or steam must flow smoothly through the turbine for it to function properly. If the stream is erratic or oscillatory, it may cause irregular rotation of the blades. That uneven rotating can cause the tur- bine to produce less clean energy than it could. This can cause turbine wear and even damage that would necessitate a complete tow truck breakdown.

The second principle is that the guide vanes are lined up correctly to give as smooth and even a path for the water or steam. This slow, gradual flow reduces the amount of wasted energy-energy that could otherwise go into generating more power for a turbine. And it does not only helps to preserve, but at the same time is a money saver; this serves companies and households which are everything.

In terms of service loads are concerned, turbines often work under severe conditions like continuous flow steam or water with even debris-bearing liquids. When the guide vanes are damaged or out of place, overall performance of the turbine will be affected. Backward adaptive are tray of guide vanes which results in low efficiency power production.

This is why we need to maintain the guide vanes properly, Also, you should be regularly checking your surrounds and keeping them clean. By regularly inspecting and fixing guide vanes, turbine operators can prevent complications from arising that would impede or stall the operation of a functioning unit. This prevents downtime for maintenance and repairs that come with a hefty price tag.

We know guide vanes have to be in the right position. Serious mathematics are involved here, they use highly detailed computer models to essentially see how water or steam will actually move through the turbine based on a set position of guide vanes in different scenarios. This technology allows them to know the exact place where they have tot put or adjust guide vanes so that turbine work in a best efficient way possible.

Our company is committed to strict quality control guidelines to ensure the highest quality and reliability of every component Quality control is conducted throughout the entire manufacturing process from the purchase of guide vane in turbine to the test of the finished product We also perform regular quality audits and improvements to ensure continuous improvement in the quality of our products Our aim is to earn the trust and long-term cooperation of our clients by offering quality products that are of the highest standard and to be a leader in the industry

Our company provides specific services that is able to manufacture turbine parts from an array of high-temperature metals to meet customer needs. If it's a particular shape, size or performance requirement, we are able to meet it using our flexible production process and the latest process technology. We stay in close contact with our clients to comprehend their individual requirements and scenarios, and provide them with expert technical guidance and solutions. We have a broad range of materials and processing capabilities to meet the unique needs of various industries and applications. Our clients can improve their guide vane in turbine by providing specific services that maximize performance and reduce costs.

Our customer support is guide vane in turbine and includes technical assistance, pre-sales advice and after-sales assistance to ensure our customers have the best possible experience. Our experienced team will review the needs of customers and offer the most effective solution and recommendations for the product. We provide technical support starting with the selection of products to installation and commissioning. This guarantees that our clients are able to enjoy our products without problems. We have a well-developed after-sales service that allows us to react quickly to customer requests and problems and provide quick and timely solutions. We strive to establish long-term relationships with our customers and earn their trust and respect by providing quality service.

Our company is able to fabricate highly precise and stable turbine components through casting, forging and CNC machine processes. The casting process permits us to guide vane in turbine with complex shapes and high durability, while the forging process gives the parts better mechanical properties and longer lasting. CNC cutting-edge technology, on contrary, provides the highest precision and accuracy of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have an experienced technical team who continuously carry out technological innovation and process improvement to make sure that our products are always at the top of the industry in terms of technology. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continually.