Jet engines are fantastic machines that create an important job in keeping planes flying way up over the ground. The engines, as illustrated here by GE 's diagram of a turbofan, are complex assemblies with many components that all have to function in concert to spin the fan at just the right RPM so they can propel an airplane through the sky. The compressor blade is the most significant part of a jet engine. In this post, we take a look at how these blades operate and why they play such an important role in our lives, as well as examine some of the ways that wind turbine blade technology is evolving.

The job of compressor blades in a jet engine. They suck in the air from outside and squeeze it, making that air smaller & tighter before it enters another section of the engine called a combustion chamber. A whole bunch of air gets compressed into a small space, and fuel comes in, too... They mix together & make a big explosion that helps the engine run. Because they work with hot and perform under high pressure generated during engine operation, these blades should be extra strong. The engine would not function properly without these blades, and the plane could not fly.

Through technological and engineering advancements, jet engine compressor blades have evolved significantly over the years. Traditionally, these blades were simple to manufacture due their basic metallic composition. But as technology got better, engineers started to come up with new compressor blades made out of other materials: ceramic and special plastics. The new designs enable the blades to withstand higher temperatures and pressures, as well as are lighter in weight than their metallic predecessors. As a result, modern jet engines are not just more fuel efficient but also produce greater power and offer aircrafts faster travels over longer ranges.

One key to providing the best performance from jet engines is adequate servicing of their compressor blades. Blades, especially when damaged or worn out can have a direct effect on performance and so regular checks (and inspections of blades) to ensure that they are not part cracked will help protect the installed wind farm investment. Blades are cleaned by the safe and reliable rise-and-wash technique, which protects blades from rust formation in addition of making them bright. Sometimes, you may also need to fix the blades or in many cases even had new ones. With properly maintained blades, the engine will function in a safe manner to avoid accidents and long-term functionality of the motor.

There are some scientific principles behind the functionality of compressor blades. The rotating blades act like a compressor, pulling air from the outside and inwards to then squeeze it which heats up the air due to compression. The more squeezed compressed! This compressed air is then mixed with the fuel and ignited, which causes a powerful explosion that pushes the engine on its way down. How the blades are shaped and positioned has a lot to do with how well they compress the air. The angle of the blades and its size needed to be perfectly designed. This maximizes the power required for the engine to work properly as well- by compressing air effectively.

What materials go into making compressor blades is key to how well they function in a jet engine. Among blades, metal is the most durable (versus plastic or glass). Those made from stainless steel also wont warp over time due to heat. On the flip side, ceramic blades are lightweight and less porous to heat - however more brittle and susceptible to chipping. Due to their light weight, strength and heat & pressure capabilities, composite blades are a prime choice for engineers. Therefore, when designing and selecting compressor blades engineers must take into account the benefits and pitfalls of each material so as not to compromise engine performance.

We adhere to jet engine compressor blades of quality control in order to guarantee the performance and reliability of every component. Quality control is performed throughout the entire manufacturing process starting from the purchase of raw materials through the test of the finished product. In order to ensure that our product's quality is continuously improved, we also conduct regular audits and improvement. Our goal is to win the trust and cooperation of our clients by offering top quality products and to become a leader in the industry.

Our customer support is jet engine compressor blades and includes technical assistance, pre-sales advice and after-sales assistance to ensure our customers have the best possible experience. Our experienced team will review the needs of customers and offer the most effective solution and recommendations for the product. We provide technical support starting with the selection of products to installation and commissioning. This guarantees that our clients are able to enjoy our products without problems. We have a well-developed after-sales service that allows us to react quickly to customer requests and problems and provide quick and timely solutions. We strive to establish long-term relationships with our customers and earn their trust and respect by providing quality service.

Our company offers a variety of customized services, and produces turbine components from an array of high-temperature jet engine compressor blades to meet the requirements of our customers. Our flexible production process and advanced technology for processing and our ability to satisfy specific requirements, such as size shape, performance, or shape, allows us to achieve every need. We communicate closely with our customers in order to fully understand their individual requirements and situations and offer expert advice and solutions. We offer a wide range of materials and processing capabilities to meet the specific demands of various industries and applications. Through customized services, we help our customers optimize product performance and efficiency and increase competitiveness in the market.

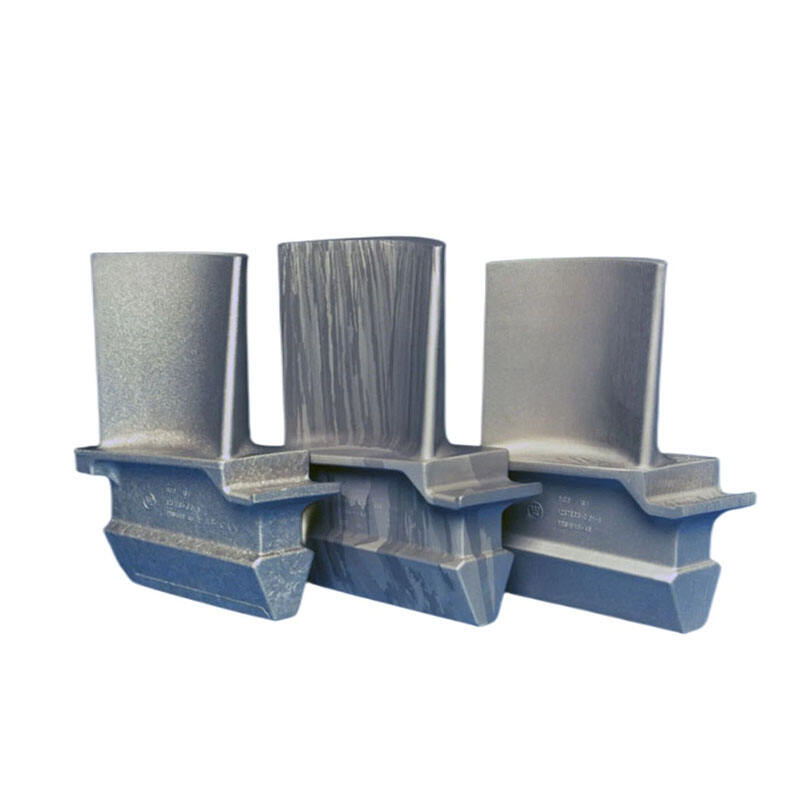

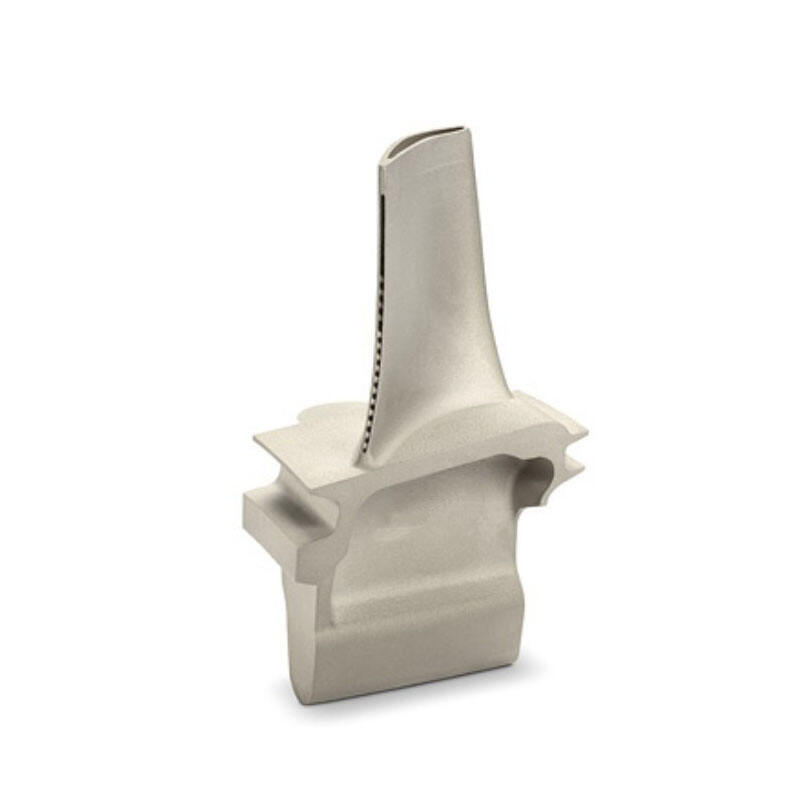

We are able to create turbine components with high accuracy and consistent quality through CNC machining, casting and forging processes. Casting allows us to create parts with complex shapes, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC jet engine compressor blades technology, on other hand, ensures the highest precision and accuracy of each piece, minimizing mistakes and ensuring that the product is of a high standard. Our highly skilled technical team is continuously developing technological advancements and process optimizations in order to keep our products at the cutting-edge of technology in the industry. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continuously.