Gas turbines are essentially giant spinning wheels (we call them "turbines") connected to a generator, where the spin creates electricity. The spinning is critical since it produces an energy flow capable of servicing homes, schools and businesses. The turbine uses blades to help move the wheel around and create energy. The blades are covered in a material to keep them sharp and operating smoothly.

The coating on the turbine blades has a lot to do with helping them function better, and last longer. By designing turbine blades with these special materials, a simple coating makes the blade stronger and more resistant. Its also means that they can take more work and extend the durability to a degree of tougher conditions. A surface that can withstand high temperatures, pressure and provide protection against damage to the blades is key for this purpose.

Gas turbine blades have to be protected using a special coating technology. The technology requires adding a protective coating to the blades that can withstand tough conditions inside the turbine. The coatings they are using will protect the blades against extremely high temperatures that can cause them to degrade. In addition, they are also believed to be useful in rust prevention as moisture and chemicals can cause the blades to oxidize. These coatings also minimize the amount of wear the blades see and keep them working for a more extended period.

The expert coating solutions can be used so that the blades are in a grea0ter way and no longer. These are coatings that can be worn on the blades to allow them to withstand damage, wear off over time and yet create an effect. This way they can ensure their blades work efficiently for longer periods. This allows the turbines to produce more power per use. Blades can effectively slice through debris coated with the correct material to allow for turbulence reduction and sustained energy production.

These advanced coating technologies have the potential to significantly increase efficiency and durability of gas turbines. Such technologies coat the blades using new materials and methods to make them stronger and more efficient. If the blades work more efficiently, then less fuel is needed to run turbines able to generate more electricity. This is key for our work not only in order to improve the performance of turbines using less fuel, but also because it reduces emission and helps save our environment. Such is the drive for reducing emissions that we can all help save our planet...by using fewer fossil fuels.

Since turbine blades are so susceptible to the wear and tear brought about by both rust, as we noted before, in addition to those other corroding elements such as wind opening up blisters or furrows into their surfaces that would subsequently put them out of commission if not completely destroy them altogether right on site. Wear can be caused by high-powered gas flows pressing the blades, and rust occurs when moisture or harsh chemicals come into contact with them. Like any type of damage, the best way to keep blades in good condition is to protect them and applying protective coatings can safe guard them from both. This keeps the turbines working correctly and perform at optimum levels over decades of operation.

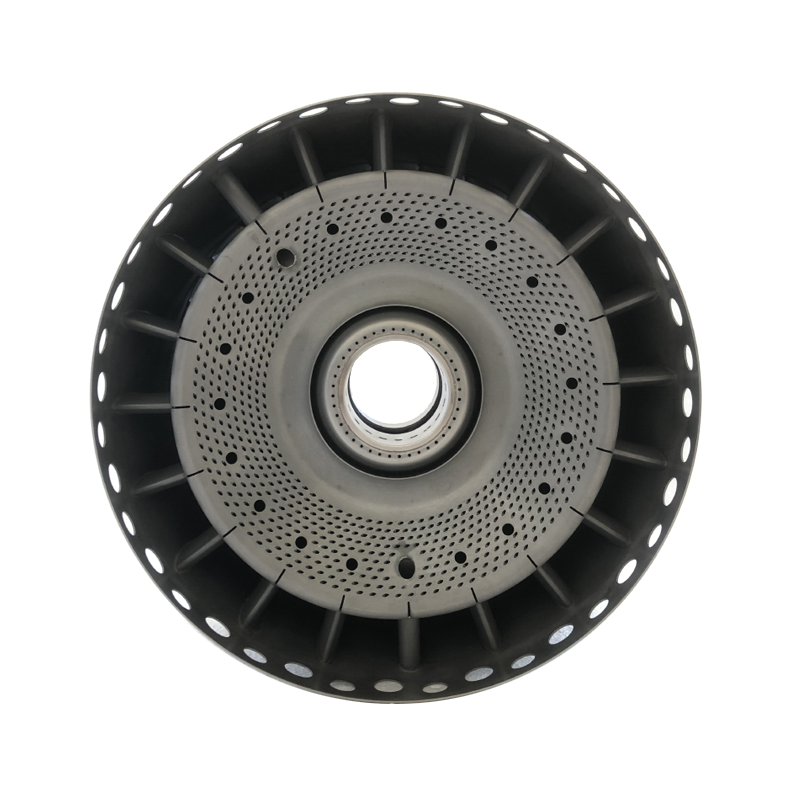

Our company offers specific services that is able to manufacture turbine parts from various high-temperature alloys in order to satisfy the demands of customers. Our flexible production flow as well as our state-of-the-art process technology and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet every requirement. We are in constant contact with our customers in order to fully understand their needs specific to them and the application scenarios, and provide them with expert technical guidance and solutions. We have a rich selection of processing and materials that can meet the gas turbine blade coating of various sectors and application. Through customized services, we assist our customers in optimizing their product performance and cost, and improve market competitiveness.

Our company is able produce highly accurate and consistent turbine parts by casting, forging, and CNC machining processes. The casting process allows us to produce parts with intricate shapes and strong durability, while the forging process gives the parts better gas turbine blade coating and longer lasting. CNC machining technology, on the contrary, guarantees consistent and high-quality of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have a highly skilled technical team that constantly carries out technological innovations and process improvement to make sure that our products stay in the forefront of industry in terms of technological. We are committed to meeting the requirements of our customers for components that are high-performance by developing technology continually.

We follow gas turbine blade coating for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.

Our complete customer service package includes technical assistance pre-sales advice and after-sales assistance to ensure that our customers receive the best experience possible At the time of pre-sales our team of experts will be able to understand the needs of the customer in detail and provide the most appropriate product suggestions and solutions We offer technical assistance from the selection of products through installing and commissioning This guarantees that our customers are gas turbine blade coating to use our products without any issues We have a well-developed after-sales system that allows us to respond quickly to customer concerns and issues and provide efficient and prompt solutions We aim to build long-term relationships with our clients and earn their trust and satisfaction by providing quality service