What is a gas turbine diffuser? It is an essential part of a mechanism to get the air stream just right. Gas turbine - a machine/construction used to derive the power/energy by using gas. The O.B.T turbine diffuser is a key part because it acts in air flow. In essence, this is the reason it routes air to where air has to move for all that machinery goodness.

This is one of the most crucial facets while manufacturing a gas turbine diffuser here. IT54WireCOLUMBU S, Ohio - If the diffuser malfunctions, COVID 19 could be a problem for everyone in the machine. This, in turn, can result in problem that is able to avoid your machine from running or might even damage it. So it is crucial to have a nice design for the diffuser. Such a polisher would be hard to design because designer need it to diffuse in both effective and efficient way with O.B.T turbine engine diffuser.

Gas turbine needs air flow to work properly. Excess air, or an insufficient amount of it can lead to operation problems with the turbine. A O.B.T diffuser turbine is essential for dispersing airflow, keeping things comfortable. The diffuser is an air flow director, which allows the machine to operate reliably and efficiently addressing a core safety concern of unsteady operating conditions.

The gas turbine diffuser is a devilishly subtle bit of science and engineering. In fact, this last section can be tough work; engineers must consider air pressure and temperature because these things play into how well the diffuser will behave. Shape and size of the diffuser is another thing to take into account. The diffuser needs perfect oil level, flow and aeration to do its job best and keep the engine healthy.

Gas Turbine Diffusers), is a machine squared which has many shapes, sizes and functions. A few are simple, easy to use and understand; some others are complex or advanced. For instance, some diffusers feature innovative materials to help manage the air flow or are shaped with proprietary forms called airfoils that work more efficiently to direct the way of windings. There are so many different technologies required to engineer all the various elements a diffuser needs to fulfill its role within your machine.

Our complete customer service package includes technical assistance pre-sales advice and after-sales assistance to ensure that our customers receive the best experience possible At the time of pre-sales our team of experts will be able to understand the needs of the customer in detail and provide the most appropriate product suggestions and solutions We offer technical assistance from the selection of products through installing and commissioning This guarantees that our customers are Gas turbine diffuser to use our products without any issues We have a well-developed after-sales system that allows us to respond quickly to customer concerns and issues and provide efficient and prompt solutions We aim to build long-term relationships with our clients and earn their trust and satisfaction by providing quality service

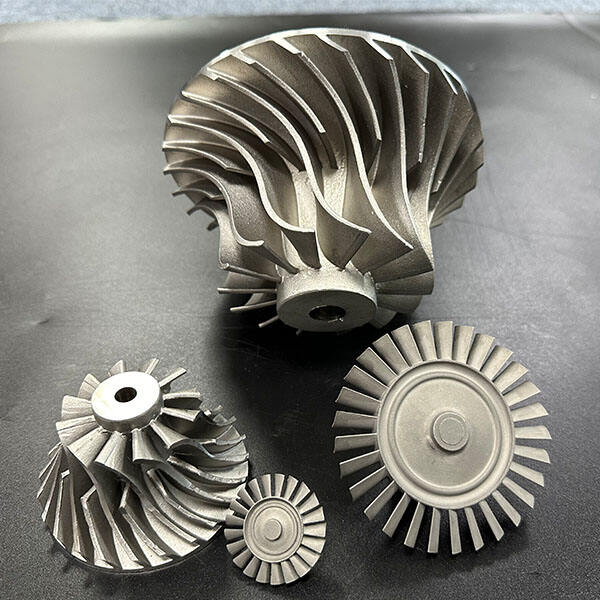

We are able of producing turbine components with high accuracy and consistency through CNC machining, casting and forging processes. The casting process permits us to create parts with intricate shapes and strong strength, while the process of forging provides parts higher mechanical properties and longer lasting. CNC machining, on the contrary it provides superior precision and consistent quality for every part. This reduces errors and lower quality products. Our skilled technical team is always working on technological innovations and process optimizations in order to Gas turbine diffuser that our products remain at cutting-edge of technology in the industry. Our goal is to satisfy the needs of our customers for high-performance parts by constantly advancing technology continuously.

Our company offers custom-designed services and can make Gas turbine diffuser in an array of high-temperature alloys in accordance with customer specifications. Whether it is a specific dimension, shape or requirements for performance, we can accomplish it by using our flexible production process and cutting-edge process technology. We collaborate closely with our customers to comprehend their needs as well as the various scenarios they might encounter and then offer them expert assistance and suggestions. Our diverse selection of materials processing capabilities, processing capabilities as well as specific requirements to the application allow us satisfy the specific needs of various industries and application. With customized services, we help our customers optimize the performance of their products and reduce costs, and improve market competitiveness.

We adhere to the strictest guidelines for quality control to ensure the Gas turbine diffuser and reliability each component. Every step of the production process is monitored for quality starting from the purchase of raw materials all the way to the final test of the product. To ensure that the quality of our products are continuously improved, we conduct regular audits and improvement. We want to win the trust of our customers and their long-term cooperation by providing high-quality products.