A gas turbine is a specialized type of machine used to generate mechanical power or electricity based on the efficiency of combined cycles. They are used in many places; power plants, airplanes and even ships - you name it Blades are key parts inside these gas turbines. These impellers are crucial as they cause the energy required to run many things we utilize in our daily basis. Gas turbine blades are manufactured to be strong and high-performance, which means they not only have straight physical properties but also work actively in order for the gas turbines do their job finely.

On any given day, you have gas turbine blade manufacturers that are producing hundreds and thousands of blades. They achieve this by using advanced machines to quickly form the blade shapes. Producing such blades at high speeds also enables them to capitalize on increasing demand for the semiconductors. The equipment used in the production is characterized by high precision. In other words, they are created in such a way that every blade is going to be manufactured its proper form and size for it so as to work according inside the gas turbine.

Indeed, sans technology the effort goes haywire in manufacturing gas turbine blades. The blades are designed with the aid of computer software by most manufacturers. This are computer programs, which support efficient design of the blades for it to work properly once they are manufactured. One more; the machines used for production of blades are very high tech. They typically use lasers and robots to craft the blades with precision. This high-tech process ensures each blade is precision-tuned to perfection, an ideal trait for a performance package. Features:

In the manufacturing due course of a gas turbine blade, it is highly important to maintain high quality. The blades tell a lot about not only safety of the companies but also efficacy. To meet these standards, manufacturers must inspect the blades at every stage of production. These blades are tested meticulously to ensure safety and performance so they provide full Inspections, and Testing of each blade through nondestructive tests. All blades are finally tested to ensure they will work in a gas turbine before being shipped off to customers. This quality assurance is necessary to establish trust with customers and make certain that the blades function properly.

The direct competition that gas turbine blade manufacturers would likely be dealing with is from companies across the globe. To compete they have to be sure their knives are good and also competitively priced. If they want to manufacture more blades in less time, they should be very effective at work. Numbers of the organizations obtain modern technology to boost their developing processes and in addition these corporations enhance high-quality of blades. This allows then to get the edge on their competition and better service their customers.

Manufacturers of gas turbine engines blades are always striving to find new and better approaches for the production thereof. New materials that are stronger and more resistant to the elements than anything ever used in our field as been a consistent theme. These new materials allow for longer-lasting and more efficient blades to be developed under different circumstances. There are also manufacturers that seek aerodynamic alternatives for their blades. This would involve achieving the design of blades that could move through air better, and then generate even more power as a result.

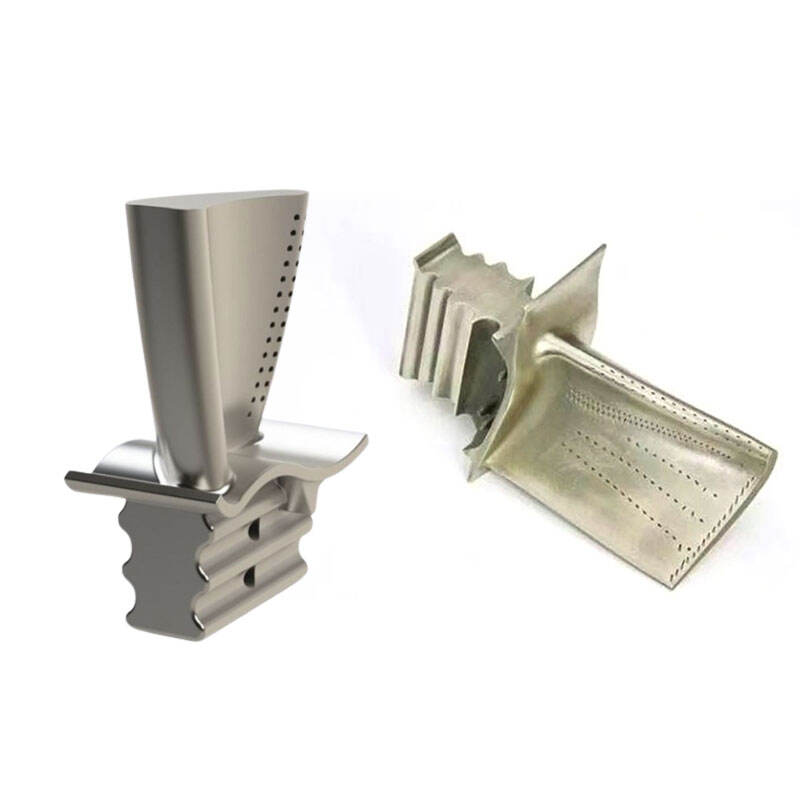

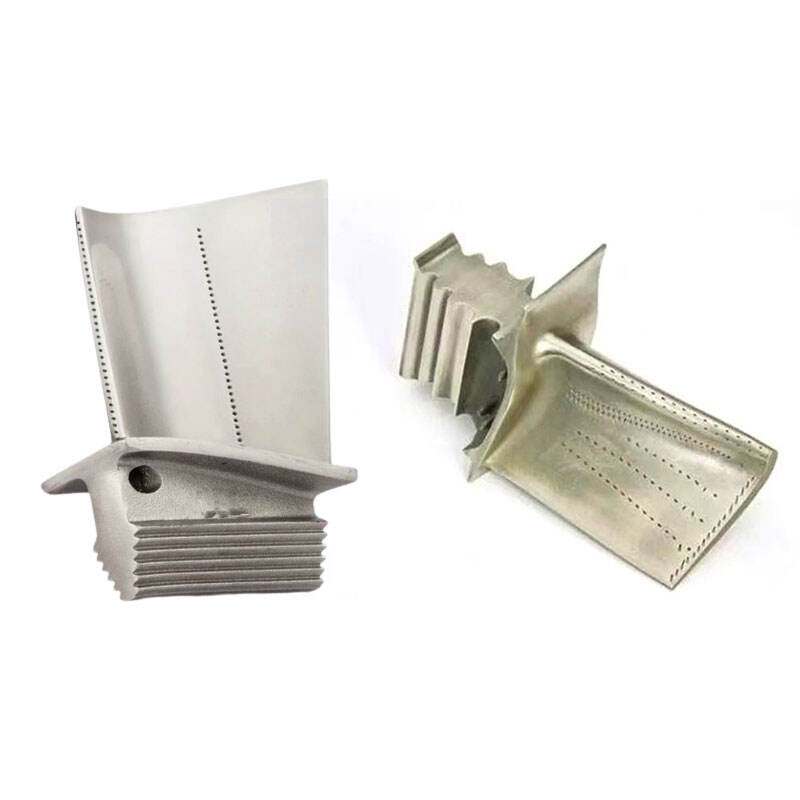

Our company offers a variety of custom-designed services and is able to manufacture turbine parts from various high-temperature alloys to meet the requirements of our customers. Our gas turbine blade manufacturers along with our advanced process technology and our capability to meet specific requirements, such as size shape, performance, or shape can allow us to meet every need. We work closely with our customers to understand their specific needs and application situations and offer expert technical guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements to the application allow us meet the requirements of various industries and application. With our customized services, we assist our customers in optimizing their the performance of their products and reduce costs, and improve market competitiveness.

We are able to create turbine components with high accuracy and consistent quality through CNC machining, casting and forging processes. Casting allows us to create parts with complex shapes, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC gas turbine blade manufacturers technology, on other hand, ensures the highest precision and accuracy of each piece, minimizing mistakes and ensuring that the product is of a high standard. Our highly skilled technical team is continuously developing technological advancements and process optimizations in order to keep our products at the cutting-edge of technology in the industry. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continuously.

Our customer support is comprehensive and includesgas turbine blade manufacturers, technical support, and after-sales services to ensure that our customers get the best experience possible. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support starting with the selection of products to installation and commissioning. This ensures that our clients are able to use our products without any issues. We have a well-developed after-sales process that allows us to swiftly respond to issues and needs of customers, and to provide effective and prompt solutions. We are determined to develop long-term relationships with our clients and gain their trust and respect by offering high-quality services.

We follow gas turbine blade manufacturers for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.