Manufacturing gas turbine blades is so much more interesting and meaningful in real life! The gas turbines have these special parts which are known as the blades. Turbines are machines which produce energy used for power plants, airplanes and a variety of other devices that rely on them to keep things moving. In producing these blades, workers must exercise extreme care and precision as even a minor error can lead to significant trouble.

Creating Gas Turbine Blades: A Computerized Process Step 1 - Design of the blades on a computer. Designers use special software that enables them to construct a 3D representation of the blade. It is the 3D image that appears as a model how it will be on blade. After that they can put this model to test all the data is correct before moving forward.

Once the model is prepared and tested, it's time to manufacture a mold. A mould is a type of shape that exactly appears like the blade. This is used to create the ultimate blade. These are high-performance blades as they need to withstand very hot temperatures and pressure where these materials are specifically made for the look of a special metal with great taste.

There's a science to creating gas turbine blades, not just art You must be very knowledgeable about materials, material processes and engineering principles. The metal used to create the blades needs to be incredibly strong so it can survive those high temperatures and pressures a gas turbine creates.

The creation of, and elements to perfect in order for those things to spend days acting like a lawn ornament on your table lol - however that is allll part of the glory years/ hard earned badge collecting wayyyy shall we? Designers have to consider the way air will circulate around your blade, which materials should be used in order to shape it and how manufacturers are supposed to correctly produce your blade. All these parameters are essential in assuring optimal operation of the gas turbine.

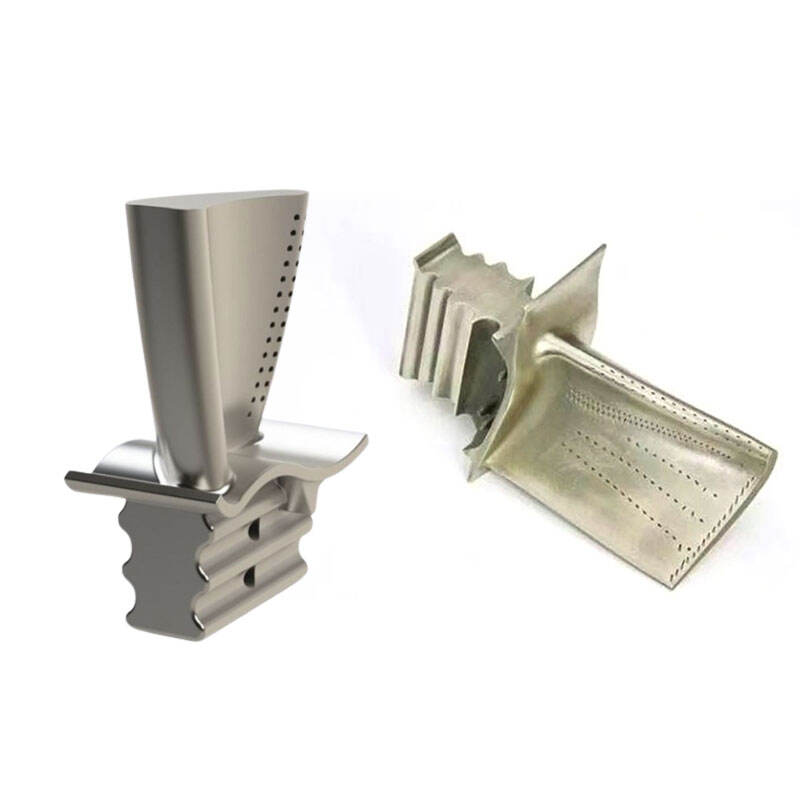

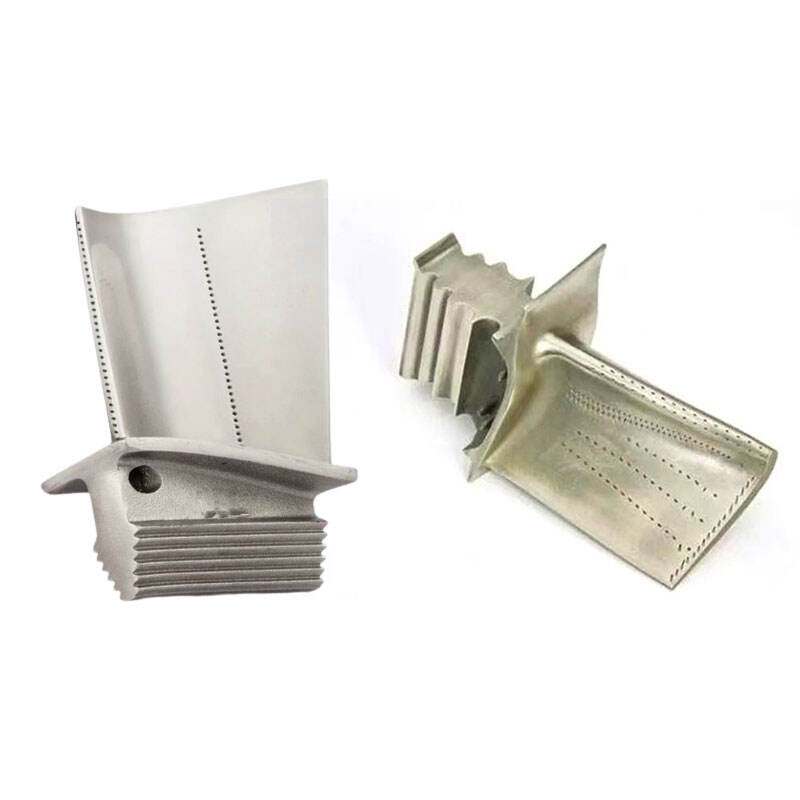

Over the years, there have been numerous interesting new concepts for designing gas turbine blades. Additive manufacturing or 3D printing (a new idea, fairly unique) This technique helps to form shapes and structures that are intricate, complex or just downright impossible to create with a traditional method of manufacturing. Additive manufacturing also affords the opportunity to create blades as demand dictates, rather than produce them and hold inventory. This can help to save a lot of time, money.

A second new approach is through the use of innovative coatings which can be added to a blade. These coatings could help the blades to last longer by protecting them from damage like erosion and corrosion. Which would also mean the blades themselves could be higher performing, and more reliable than ever before: even more efficiency squeezed out of gas turbines.

We adhere to gas turbine blade manufacturing of quality control in order to guarantee the performance and reliability of every component. Quality control is performed throughout the entire manufacturing process starting from the purchase of raw materials through the test of the finished product. In order to ensure that our product's quality is continuously improved, we also conduct regular audits and improvement. Our goal is to win the trust and cooperation of our clients by offering top quality products and to become a leader in the industry.

Our complete customer service package includes technical assistance pre-sales advice and after-sales assistance to ensure that our customers receive the best experience possible At the time of pre-sales our team of experts will be able to understand the needs of the customer in detail and provide the most appropriate product suggestions and solutions We offer technical assistance from the selection of products through installing and commissioning This guarantees that our customers are gas turbine blade manufacturing to use our products without any issues We have a well-developed after-sales system that allows us to respond quickly to customer concerns and issues and provide efficient and prompt solutions We aim to build long-term relationships with our clients and earn their trust and satisfaction by providing quality service

Our company can provide customized services and is able to fabricate turbine components from an array of high-temperature alloys in accordance with the requirements of customers. No matter what gas turbine blade manufacturing, size or performance requirement, we can achieve it with our flexible production process and cutting-edge technology for process. We work closely with clients to comprehend their needs as well as the various scenarios they might encounter and give them professional assistance and suggestions. We have a variety of materials and processing capabilities to meet the unique requirements of different industries and applications. We aid our clients in improving their competitiveness on the market by offering custom-designed services that improve efficiency and lower costs.

Our company is able produce highly accurate and consistent turbine parts by casting, forging, and CNC machining processes. The casting process allows us to produce parts with intricate shapes and strong durability, while the forging process gives the parts better gas turbine blade manufacturing and longer lasting. CNC machining technology, on the contrary, guarantees consistent and high-quality of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have a highly skilled technical team that constantly carries out technological innovations and process improvement to make sure that our products stay in the forefront of industry in terms of technological. We are committed to meeting the requirements of our customers for components that are high-performance by developing technology continually.