You know better, cmon ever heard of a guide vane turbine? The device used by us to produce electricity is a Special type of turbine (Water Wheel). It is typically a jet turbine connected to spinning as described above, but the water (from for example a river) is used instead of gas (air). Think about it, this water motion technology could be sent through an incredibly small engine and at home or school.

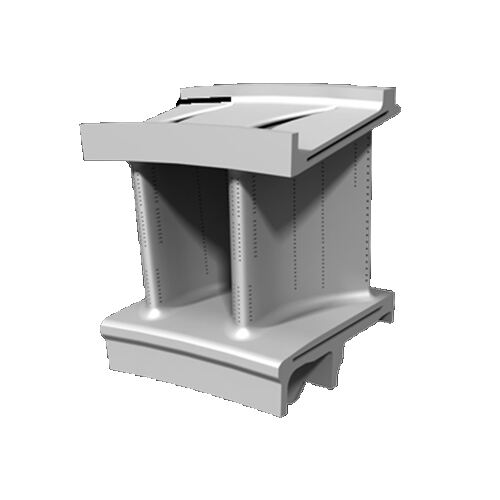

A set of guide vanes turbine: it operates on the principle that water is all made to flow over the relatively larger wheel called as a turbine which causes its rotation. In an hydroelectric power plant (like this one), the water is caught in a rain fall reservoir or flow that's directed towards wind generator, which can be component of any turbine and also produces electricity. Examples : If steam Turbines Impeller in case of Internal Combustion and compressor for Jet engines Water is the working fluid. And Guide Vanes- these are specific parts of M/C from where water enters before reaching to turbine Water is channeled to the turbine, helping the blades of turbines into converting energy in electricity easily.

These guide vane turbines have efficiency due to which it convert water flow into electric current and thus increase the viability of hydroelectric energy. The water that enters the turbine is moving fast and under pressure, so it very is high-energy liquid. This power is used to generate electricity and provide it in our residential places as well as office units. Guide vane turbines differ in size, some may be large and others small on the amount of electricity needed

One of the most flexible turbines are Guide Vane Turbines. This is they are flexible enough to be customised and provide the services that people in those areas will use. Guide vane type turbines can be used to generate electricity in the mountains, without any power grids or sources of running water. In cities, they can be similarly used to power houses and businesses with clean energy. There is also the fact that such a turbine - guide vane turbines, with their help can be receive electricity for many years without special repairs and interruptions.

Therefore, the guide vane turbine has many advantages and is a good choice for generating electricity. The best of all, they produce zero greenhouse gas emissions. That is simple before this nuclear waste product was very toxic unlike normal power plants as on its way out bad chemicals were released into the air. Also, not how it uses no dirty space wasting nonrenewable resources like coal and oil. The great advantage of guide vane turbines is the production of a lot electricity with little water. Which in turn, we have to use less energy somewhere else (by processes which is releasing the fossil fuels). It is very useful for the environment as it means we need less of our scarce diesel fuel, and burning century-old tropical forests or oil to generate electricity using guide vane turbines formidably cleaner-burning coals ( still a polluter ) than that.

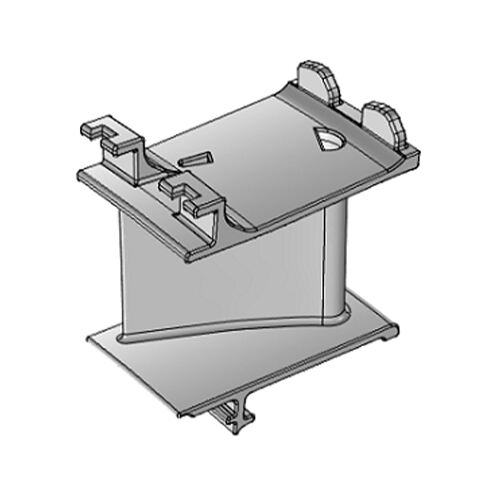

Our company offers customized services, and can produce turbine components from an array of guide vane turbine metals to meet the needs of customers. Our flexible production flow, advanced process technology, and our capacity to meet particular requirements, like size shape, performance, or shape can allow us to meet any requirement. We work closely with our clients to comprehend their needs specific to them and the application scenarios and provide professional advice and solutions. Our diverse selection of materials, processing capabilities and application-specific requirements allow us to meet the needs of a variety of industries and. With customized services, we help our customers optimize product performance and cost as well as increase market competitiveness.

Our company has the ability to create highly precise and reliable turbine parts through casting guide vane turbine, and CNC machining processes. Casting allows us create components with complex designs, strong and long-lasting. Forging provides parts with a better mechanical quality and longer durability. CNC machining, on the contrary offers high precision and consistency for every component. This reduces errors and inferior products. Our technical staff is constantly developing technological advancements and process improvements to ensure our products are at the forefront of industry technology. We're committed to meeting our customers' demands for high-performance turbine components by continual technological advancement.

Our company is committed to strict quality control standards to guarantee the best performance and reliability of every component Every step of the production process is controlled for quality starting from the purchase of raw materials all the way to the final test of the product We also carry out regular quality audits as well as adjustments to ensure constant improvements in product quality Our goal is to win the trust and continue to work with of our clients by offering top quality products and to become an guide vane turbine

Our customer support is guide vane turbine and includes technical assistance, pre-sales advice and after-sales assistance to ensure our customers have the best possible experience. Our experienced team will review the needs of customers and offer the most effective solution and recommendations for the product. We provide technical support starting with the selection of products to installation and commissioning. This guarantees that our clients are able to enjoy our products without problems. We have a well-developed after-sales service that allows us to react quickly to customer requests and problems and provide quick and timely solutions. We strive to establish long-term relationships with our customers and earn their trust and respect by providing quality service.