Optimizing operation and prolonging lifespan with professional maintenance

Gas turbine engines are of great importance in various industries, such as aero industry and energy generation. Like all such strong devices, they needed to be maintained regularly for maximum output and lifespan. O.B.T provides professional maintenance services that promote performance and longevity in gas turbine engines for years to come. “We strive to give our top level maintenance services to clients from all different types of industries, whether they are commercial or residential,” says O.B.T, whose team of expert technicians and top of the line equipment is the best in the industry.

Turbo efficiency is key for enterprises who need it to aid in boosting productivity while also maintaining control of running costs. O.B.T provides a low cost solution which enables clients to have ranges according to power output for their Gas Turbine Engines without it costing a fortune. Whether it is efficient maintenance plan, while wet cleaning, innovative technology or something entirely different O.B.T ensures clients increased turbine efficiency and reduced operating cost. Advantage With its commitment to providing the market with excellence in quality and service performance at competitive prices O.B.T is the ideal choice for companies wanting to maximize their turbines performance.

“Gas turbine engine maintenance is all about accuracy. O.B.T uses the latest technology, techniques and repairs available to make precision repairs and upgrades the first time. O.B.T offers a full range of services –from quick tip trimming jobs to large, extended projects, O.B.T has the right people and equipment to get the job done right. Alongside the use of the latest advances in technology, O.B.T can deliver the highest level of service to clients looking for a solution to maintaining their gas turbine engine.

Companies whose businesses are powered by gas turbine engines know that reliability is key. O.B.T recognize the importance of the reliability, and provides thorough inspections and maintenance guaranteed to keep your gas turbine engine running smoothly and problem free. Through its comprehensive examination approach and its scheduled maintenance services, O.B.T enables clients to improve the reliability of their engines, and lower the probability of unplanned engine issues and associated costs. Dedicated to excellence and quality O.B.T is the partner of choice for companies seeking to enhance the reliability of their gas turbine engines.

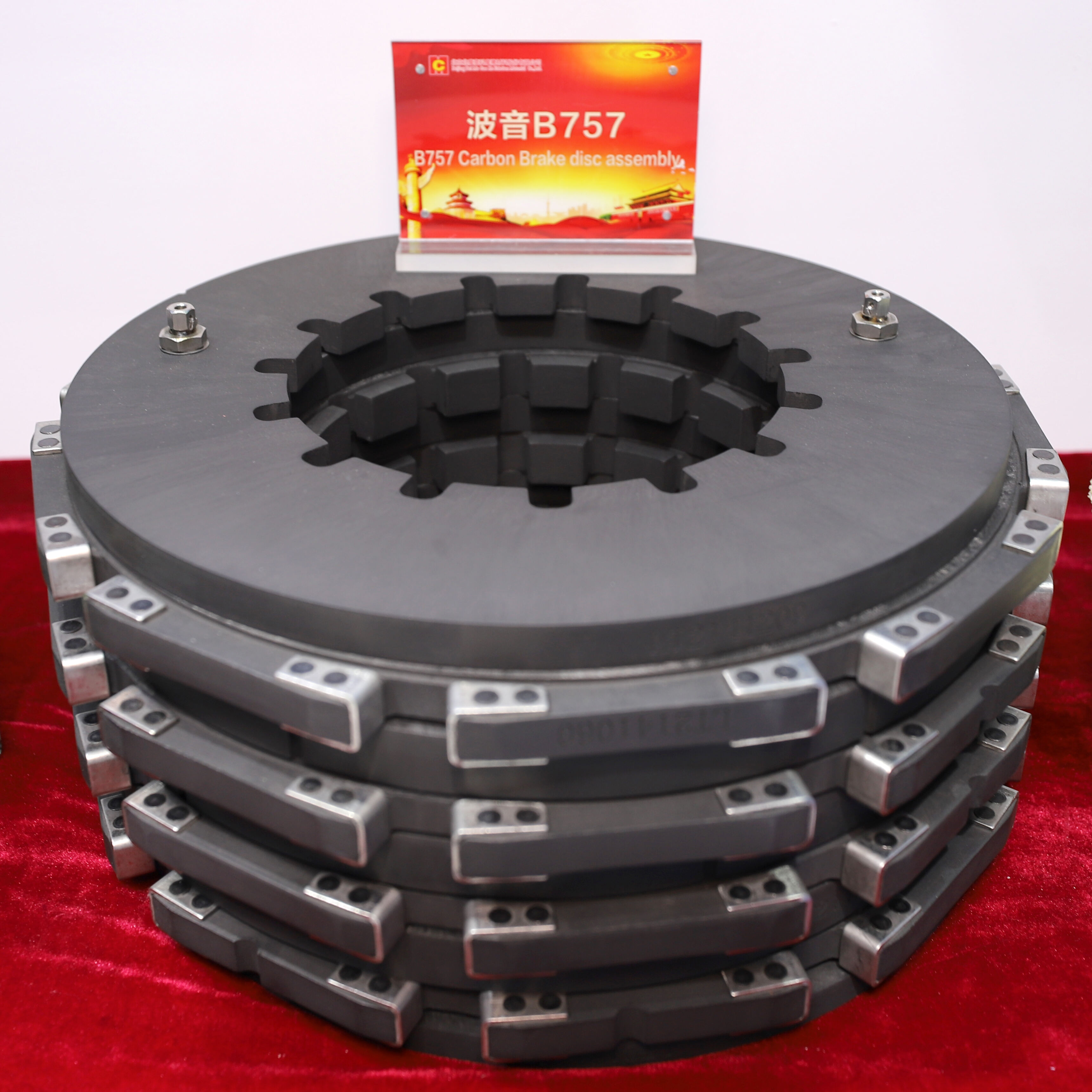

Reengineering gas turbines is a very specialized job that must be done with great precision. O.B.T holds decades of experience in high quality and precision in gas turbine engine overhaul. With years of experience combined with highly skilled technicians, O.B.T delivers outstanding Refurbishment to clients, well beyond their expectations. With system overhauls to single part exchanges, O.B.T has the capability to overhaul to the highest standards to ensure max performance and lifetime of gas turbine engines. Rely on O.B.T for your gas turbine engine overhaul requirements and feel the difference with quality and competence.

Our customer support is Gas turbine engine overhaul and includes technical assistance, pre-sales advice and after-sales assistance to ensure our customers have the best possible experience. Our experienced team will review the needs of customers and offer the most effective solution and recommendations for the product. We provide technical support starting with the selection of products to installation and commissioning. This guarantees that our clients are able to enjoy our products without problems. We have a well-developed after-sales service that allows us to react quickly to customer requests and problems and provide quick and timely solutions. We strive to establish long-term relationships with our customers and earn their trust and respect by providing quality service.

Our company provides Gas turbine engine overhaul, and we is able to manufacture turbine parts from many high-temperature aluminum alloys in order to satisfy the demands of customers. Our flexible production flow and advanced technology for processing and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet any need. We work closely with customers to fully comprehend their requirements and applications scenarios and provide them with expert assistance and suggestions. We have a broad range of materials and processing capabilities to meet the special demands of various industries and applications. Our clients can improve their competitiveness on the market by offering customized services that optimize performance and reduce cost.

Our company is committed to strict quality control guidelines to ensure the highest quality and reliability of every component Quality control is conducted throughout the entire manufacturing process from the purchase of Gas turbine engine overhaul to the test of the finished product We also perform regular quality audits and improvements to ensure continuous improvement in the quality of our products Our aim is to earn the trust and long-term cooperation of our clients by offering quality products that are of the highest standard and to be a leader in the industry

Our company has the ability to create highly precise and reliable turbine parts through casting Gas turbine engine overhaul, and CNC machining processes. Casting allows us create components with complex designs, strong and long-lasting. Forging provides parts with a better mechanical quality and longer durability. CNC machining, on the contrary offers high precision and consistency for every component. This reduces errors and inferior products. Our technical staff is constantly developing technological advancements and process improvements to ensure our products are at the forefront of industry technology. We're committed to meeting our customers' demands for high-performance turbine components by continual technological advancement.