The electricity is produced by the turbines They spin, and move really fast to create the power that we use in our homes and businesses. That does not, however, mean that all of the air entering a turbine is being used as optimally its potential. This is where vanes come in! These vanes help guide the air into a more efficient operation of turbines. This reduces the amount of airflow needed to create power for the turbine. That also accelerates the path to Baseline production and a Base material library, so that you do not have start from square one every time with your game textures-and it does all of this while minimizing waste.

YES - of course it has, Haven't you seen a pinwheel swirling in the breeze...? Warping pin wheel in powerful hot wind. In similar way a turbine works but instead of pin wheel their are special kind of blades which is rotating at very high speed. This then forces the blades as they rotate of their own accord on account power under drive air. But like the pinwheel, they never capture all of that air. This is where the veins come into play! The vanes themselves don't spin, that's down to the blades of the turbine and so what these do is direct air into the path of rotation as efficiently as possible such that more energy from all those 170mph winds gets transferred into getting those blades spinning away. This also means that the turbine uses even less air which is friendlier to our planet!

Just as well-configured vanes on a paddlewheel can make it turn faster, they enable the wind turbine to generate more electrical power using less air. Those vanes are designed to be aerodynamically efficient to move air smoothly into the turbine, so more of that energy is passing through and spinning them (hopefully). The stronger they are spinning - More electricity generated! So to let a turbine produce more electricity you mainly have high-grade lades for one, those are the jobs that makes them run most easily and effective.

A variable vanes, however are exactly that and when the turbine needs more energy it will adjust its position to provide an extra. If the turbine requires a large amount of energy, the variable vanes will open up to allow more air. If the turbine on the other hand does not need that much energy to start spinning... well you know plus with it being heavier, yeah. In for 18-months and it's play time during forging steamrollers as the variable vanes pinch closed slightly to reduce air}while only a little less so than usual. This allows the turbine to work more efficiently and generate more electricity using less air. Therefore, variable vanes is very helpful to complete a variety of energy needs during the day.

Wind turbines, similar to any other machine output if long life is desired then it should be taken care of otherwise just like all machines the efficiency declines over time. I gave this care to include the vanes which needs your attention! If they get damaged or are all clogged up with goo, the vanes won't work properly and your shaver will not run at its full potential. Well the fact that it is a higher temperature is not an advantage as much of the power potential is wasted by running to fast above its self sustaining rangeecessitating more fuel consumption. This is the reason it proves to be helpful keeping clean vanes as much possible. Regular maintenance can help prevent this.

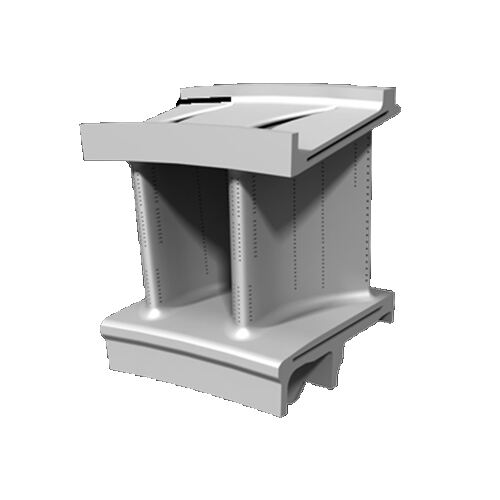

Our company offers customized services and is able to fabricate turbine components from many different high temperature alloys based on customer specifications. Our flexible production flow along with our advanced process technology and our capability to meet vane in turbine, such as size and shape, as well as performance can allow us to meet any requirement. We work closely with clients to comprehend their needs and the potential scenarios for their applications, and then give them professional guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements for applications allow us to fulfill the particular requirements of various industries and application. With our customized services, we help our customers optimize efficiency and costs of their products, and improve market competitiveness.

Our company has the ability to create highly precise and reliable turbine parts through casting vane in turbine, and CNC machining processes. Casting allows us create components with complex designs, strong and long-lasting. Forging provides parts with a better mechanical quality and longer durability. CNC machining, on the contrary offers high precision and consistency for every component. This reduces errors and inferior products. Our technical staff is constantly developing technological advancements and process improvements to ensure our products are at the forefront of industry technology. We're committed to meeting our customers' demands for high-performance turbine components by continual technological advancement.

Our customer support is vane in turbine and includes technical assistance, pre-sales advice and after-sales assistance to ensure our customers have the best possible experience. Our experienced team will review the needs of customers and offer the most effective solution and recommendations for the product. We provide technical support starting with the selection of products to installation and commissioning. This guarantees that our clients are able to enjoy our products without problems. We have a well-developed after-sales service that allows us to react quickly to customer requests and problems and provide quick and timely solutions. We strive to establish long-term relationships with our customers and earn their trust and respect by providing quality service.

Our company follows strict vane in turbine standards in order to ensure excellent performance and dependability of each component. Quality control is conducted throughout the entire production process beginning with the purchase of raw materials through the test of the finished product. To ensure that the quality of our products is continuously improved, we perform regular audits and improvements. We strive to earn the trust of our clients and their long-term partnership by providing products of high-quality.