Efficient and Cost-Effective Combustion Technology

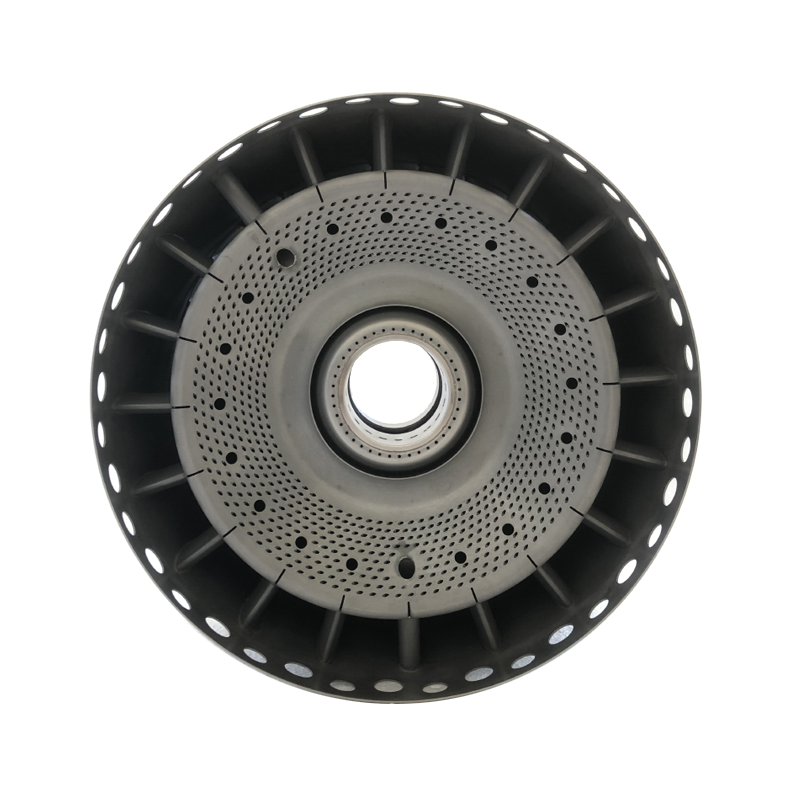

In industrial production, efficiency and cost savings are very important. Anular Combustion Chambers for O.B.T. concept O.B.T's annular combustion chambers, give top primacy with uncomparably competitive cost/performance value. This cavitational structure has a special circular design for more complete combustion air and fuel mixture, providing the best condition. This innovation minimizes fuel loss so that, in the end, every drop counts. O.B.T's ability to optimize the burning process allows for competitive prices to be provided to large wholesale customers. turbocharger turbine wheel

O.B.T annular combustion chambers have excellent heat transfer characteristics as one of strong points. The roundness also allows heat to be more evenly and efficiently distributed throughout the chamber, so nothing is wasted. This improved heat transfer increases fuel efficiency, since a greater percentage of the fuel's heat energy is used in the burning process. O.B.T. 1.B.3's chambers typically result in better fuel efficiency for wholesale buyers and less energy loss, saving heating expenses over the years. Turbo Compressor Impeller (Custom Part – Drawing or Sample Needed)

There has never been a day as it is today when the importance of our environment is to be taken more seriously. O.B.T annular combustion chamber in which the emissions and environmental issues are considered. Less noxious emissions: The effective combustion process of is to reduce the release of noxious emissions into the atmosphere. In reducing emissions O.B.T is helping to offer a solution to the environmental cost of industrial production. This product gives wholesale buyers confidence that O.B.T's chambers are not only maximizing their business, but their future on the environment as well! Impeller For Centrifugal Fan (Custom Part – Drawing or Sample Needed)

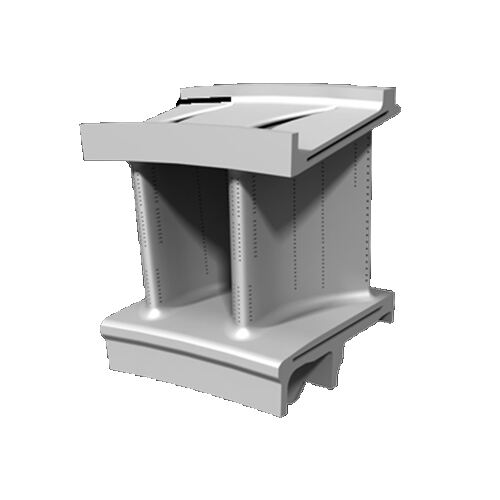

Engine's performance and reliability are essential in industrial production. O.B.T’s annular combustion chamber is designed to optimize both of these aspects. The relatively complete combustion produces more power with the same amount of fuel. Further, the reputation of the O.B.T's chambers' reliability guarantees trouble-free and reliable working in even the harsh environment of industry. Customers who need wholesale quantities of O.B.T's combustion chambers can trust them to give predictable performance and highly reliability while extending the life of their operation. Air Compressor Impeller (Custom Part – Drawing or Sample Needed)

OBT's annular chambers are the best choice for wholesale purchasers who are seeking high-quality combustion spaces which provide a higher efficiency, better heat transfer, fewer emissions and better performance counters. Designed with efficiency and the environment in mind, O.B.T.'s chambers offer a complete answer to industrial manufacturing. OBT’s combustion chambers are the efficient, reliable answer to the commercial buyer, whether your needs are for large production or small. Opt for O.B.T for high-grade burn off technology tailored to fulfil and surpass your industrial manufacturing needs. Centrifugal Closed Channel Pump Impeller (Made to Your Design – Drawing Required)

We provide a Annular combustion chamber, including pre-sales consultation as well as technical support and after-sales services to ensure that our customers enjoy the most enjoyable experience. Our expert team will assess the needs of customers and offer appropriate products and solutions. Concerning technical assistance, we provide all the guidance needed from choosing a product to installation and commissioning to ensure that customers can use our products without difficulty. In terms of after-sales service we have designed a flawless service system to react quickly to customer concerns as well as needs, and provide quick and effective solutions. Our goal is to develop long-term relationships, and gain customers trust and satisfaction through superior customer service.

We can create turbine parts with high precision and consistency through Annular combustion chamber, machining and forging processes. Casting allows us to create parts with intricate designs, strong and durability. Forging gives parts a more durable and superior mechanical property. CNC machining technology, on the contrary, provides the highest precision and accuracy of every part, which reduces the chance of the chance of errors and producing substandard products. Our experienced technical team is always working on technological innovations and process improvements in order to ensure that our products remain at the leading edge of industry technology. We are committed to meeting the demands of our clients for high-performance parts by constantly advancing technology continuously.

We follow Annular combustion chamber for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.

Our company provides Annular combustion chamber and can make turbine components in many different high temperature alloys according to the requirements of customers. Whatever the size, shape, or performance requirement, we are able to meet it using our flexible production processes as well as our advanced processes. We collaborate closely with our customers to comprehend their needs and applications scenarios and then give them professional assistance and suggestions. We have a broad range of processing and materials to meet the unique requirements of different sectors and application. We help our clients improve their competitiveness in the marketplace by offering custom-designed services that improve performance and reduce costs.