So, in case that you have ever flown on an airplane a turbine engine powers this type of plane. Whole O.B.T turbine nozzle vanes part is one of the parts are included in this machines. In the sections that follow this we are going to go into more depth on what this part uniquely does and how O.B.T. is improving upon their work with it. A UK based company

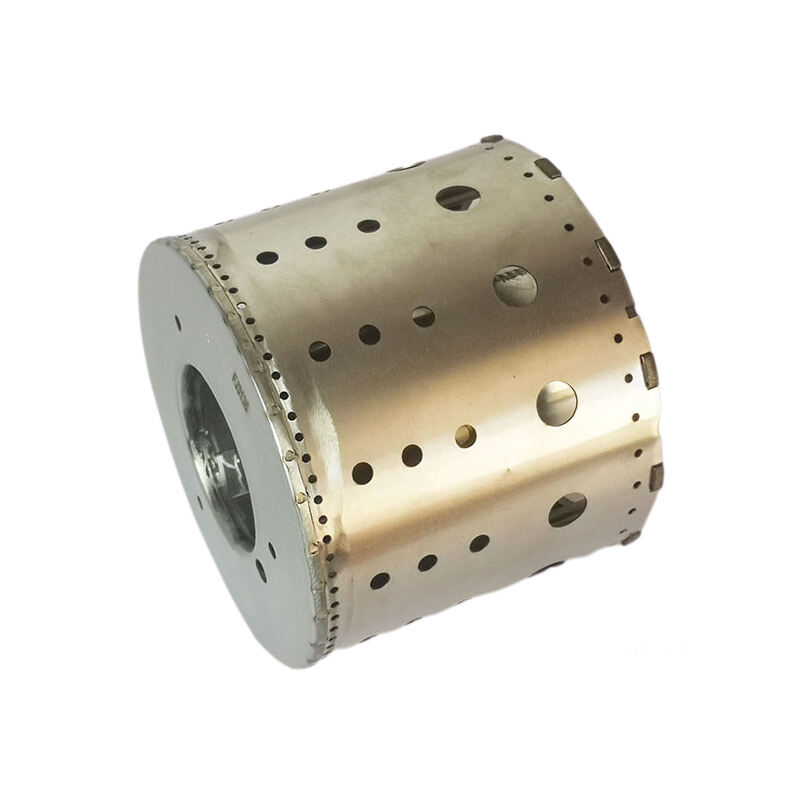

What Is A Turbine Nozzle Ring It fits between two other pieces: the compressor and the turbine. The vanes in the nozzle encounter package. Vanes that direct the flow of hot gases as they evacuate the part of an engine called the combustion chamber. This high-temperature steam then flows into the turbine, which contains spinning blades that create electricity. What do they do is they allow to rotate the turbine blades at a very high rpm and same time keeping the nozzle ring fully stationary. This configuration allows the engine to operate properly and generate flight power.

Engineers know a lot about the movement of fluids and which materials would be ideal for formation if they are making turbine nozzle ring. So we will keep you busy with that and we made software for our engineers to learn how these gases flow into the exhaust from the nozzle ring during mass constitution which is called this chemical process. With the help of this tech, they can simulate how gases move which helps them in producing best designs for the engine. In this manner, they will ensure that the gas turbine nozzle ring operates as efficiently as possible to improve engine efficiency.

Clearance: Clearance is a jumbo term which refers to the openings between the O.B.T turbine nozzle ring and spun blades. It is a very important part for the engine to run without problems. If this clearance falls in the lower side, the blades will kiss the nozzle ring causing catastrophic damage and safety issues in engine. On the contrary, if there is too large of a gap, the engine will not build boost efficiently and that might result in subpar performance. O.B.T engineers use special measuring tools to check each nozzle ring that passes through the shop, ensuring the perfect balance between clearance and fitment in any engine they land in. There is such a fine grasp of the specifics that help this engine continue running.

Damage due to Erosion Turbine nozzle rings can also be subject to erosion. The nozzle ring has holes in it which, very rapidly hot gases can get through and cause erosion over time on the metal. This passing greatly reduces the effectiveness of the nozzle ring and thus the efficiency of the engine as a whole. But engineers are have been pretty good about developing or designing the nozzle ring with some special coatings and materials to fend off erosion. In situations when the nozzle ring is already damaged, they can also repair it. So it will increase the life of nozzle ring and also make efficient.

At O.B.T we are always on the hunt for new ways to improve turbine nozzle rings. The O.B.T turbine blade learn new things about various materials available to build better performing nozzle rings or ones with longer life. From temperature-protection to help the nozzle ring lose a hot, advanced coatings serve multiple purposes. Their commitment to advanced technology helps in creating some of the finest turbine nozzle rings where they assist in saving on costs and more importantly, enhancing safety for aviation.

We follow Turbine nozzle ring for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.

Our customer support is comprehensive and includesTurbine nozzle ring, technical support, and after-sales services to ensure that our customers get the best experience possible. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support starting with the selection of products to installation and commissioning. This ensures that our clients are able to use our products without any issues. We have a well-developed after-sales process that allows us to swiftly respond to issues and needs of customers, and to provide effective and prompt solutions. We are determined to develop long-term relationships with our clients and gain their trust and respect by offering high-quality services.

Our company offers customized services and is able to fabricate turbine components from many different high temperature alloys based on customer specifications. Our flexible production flow along with our advanced process technology and our capability to meet Turbine nozzle ring, such as size and shape, as well as performance can allow us to meet any requirement. We work closely with clients to comprehend their needs and the potential scenarios for their applications, and then give them professional guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements for applications allow us to fulfill the particular requirements of various industries and application. With our customized services, we help our customers optimize efficiency and costs of their products, and improve market competitiveness.

We are able to create turbine components with high accuracy and consistency using CNC casting, machining and forging processes. Casting allows us create parts with Turbine nozzle ring, strong and durability. Forging offers parts more durable and superior mechanical property. CNC machining, on the contrary is extremely precise and consistency for each part. This eliminates mistakes and poor quality products. Our experienced technical team is continuously researching technological advances and process optimizations in order to keep our products at the leading edge of industry technology. We're committed to meeting the demands of our customers for high-performance turbine components by the continuous advancement of technology.