Wheels in gas turbines are a key component in several applications such as aerospace. These wheels are critical to driving aircraft engines, allowing them to generate thrust for takeoff and ascent. Selecting the appropriate gas steam turbine wheel is a critical decision for any aerospace endeavor because it has direct implications on aircraft performance and fuel efficiency. O.B.T has an expertise in producing high precision gas turbine wheels for Aerospace applications.

Aerodrive systems of this type are commonly utilized in the aerospace industry to produce power for aircraft engines by means of gas turbine wheels. These wheel is High Temp and Speed rated for aviation applications. In aerospace applications, gas turbine wheels are used in a type of jet engine known as turbofan engines, which compress air and mixture of fuel to enhance the thrust or power production. Weighing around 80 grams per wheel, the ultra wheels are precision machined to provide both reduced weight and maximum strength; meaning you can fly how you want, without worrying about skimping on quality. The turbine wheel manufacturers like O.B.T’s gas turbine wheels are precision engineered for the most demanding requirements in the aerospace industry, delivering reliable power to propel aircraft engines.

When you need a gas turbine wheel for your aerospace application, there are several things to consider in order to ensure that it is able to perform its task efficiently and effectively. An important factor to consider is the material of the wheel. These parts are usually made of high strength, heat resistant materials such as titanium or nickel-based alloys. The wheel configuration, e. g., blade profiles and cooling techniques are also crucial in the way how turbines operate. Moab O.B.T has a selection of Gas Turbine Wheels and Designs to meet the demands of different projects. It is important that you and O.B.T’s team of experts work together to find the perfect gas 66mm turbine wheel for your particular aerospace application, so that it runs completely smoothly and operates dependably.

When it comes to gas turbine wheels for wholesale, O.B.T has you covered with quality products that are ideal for a wide range of applications in this guide, we will discuss the benefits of choosing to buy your gas turbine Wheels in bulk and where exactly you can find high-quality options at an affordable price.

If you are interested in wholesale gas turbine wheels, O.B.T may be exactly what you need! When you buy them in bulk, you can save money by getting them at a lower price per unit. Whether you are looking for a couple of wheels, or an entire shipment O.B.T can work with you to provide the products you need to keep your business up and running.

For the best in superior quality gas turbine wheels look no further than O.B.T. At our company, we enjoy a reputation as the best wheel manufacturer in the business for consistently producing wheels that meet and exceed industry standards. With O.B.T as your vendor, you can be assured that you are receiving wheels that have the absolute highest quality of workmanship available on the market. And our super competitive prices mean that you’re getting the best value out there without sacrificing quality.

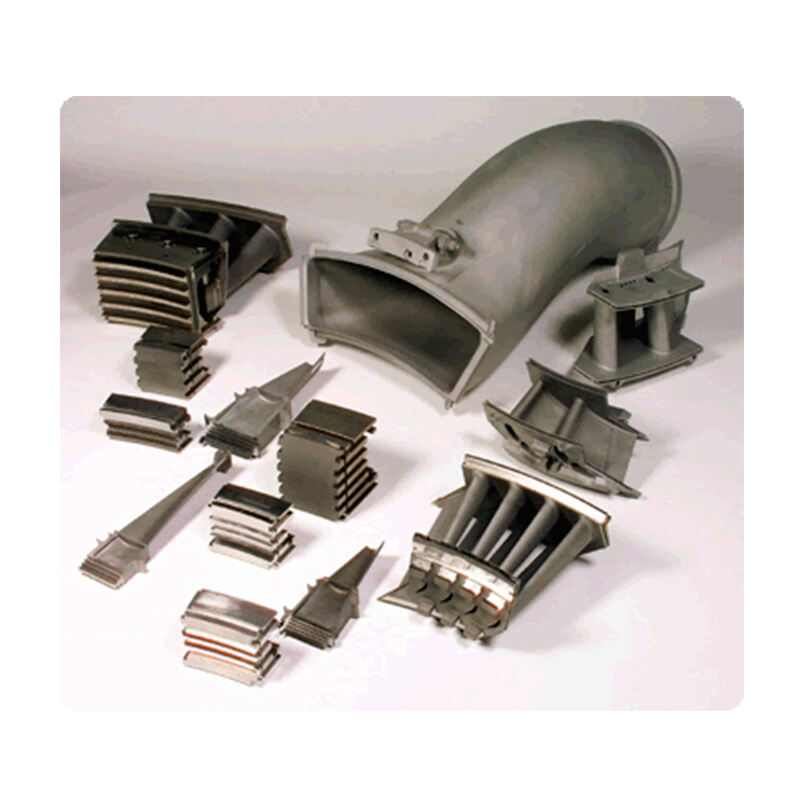

Our company provides Gas turbine wheel, and we is able to manufacture turbine parts from many high-temperature aluminum alloys in order to satisfy the demands of customers. Our flexible production flow and advanced technology for processing and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet any need. We work closely with customers to fully comprehend their requirements and applications scenarios and provide them with expert assistance and suggestions. We have a broad range of materials and processing capabilities to meet the special demands of various industries and applications. Our clients can improve their competitiveness on the market by offering customized services that optimize performance and reduce cost.

We adhere to Gas turbine wheel of quality control in order to guarantee the performance and reliability of every component. Quality control is performed throughout the entire manufacturing process starting from the purchase of raw materials through the test of the finished product. In order to ensure that our product's quality is continuously improved, we also conduct regular audits and improvement. Our goal is to win the trust and cooperation of our clients by offering top quality products and to become a leader in the industry.

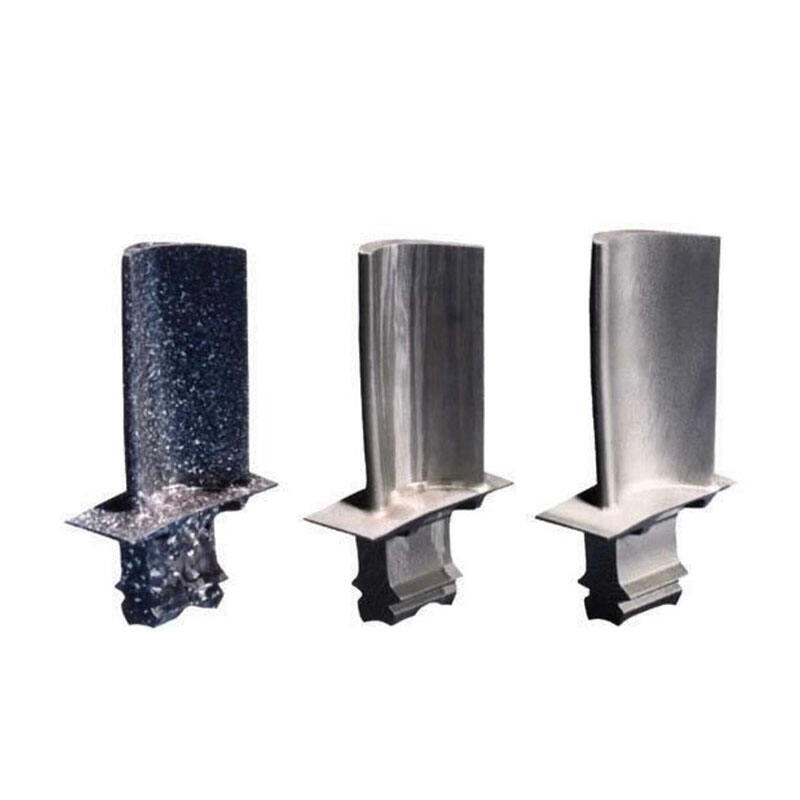

We are able of producing turbine components with high accuracy and consistency through CNC machining, casting and forging processes. The casting process permits us to create parts with intricate shapes and strong strength, while the process of forging provides parts higher mechanical properties and longer lasting. CNC machining, on the contrary it provides superior precision and consistent quality for every part. This reduces errors and lower quality products. Our skilled technical team is always working on technological innovations and process optimizations in order to Gas turbine wheel that our products remain at cutting-edge of technology in the industry. Our goal is to satisfy the needs of our customers for high-performance parts by constantly advancing technology continuously.

We offer comprehensive customer support that includes pre-sales consultation technical support as well as after-sales services to ensure that our customers have the best possible experience When it comes to the pre-sales phase our team of experts will be able to understand the needs of the customer in detail and provide the most appropriate product suggestions and solutions For technical support we offer complete guidance from selecting the product to installation and commissioning to ensure that our customers use our products without difficulty For after-sales support We have created an efficient service system that can respond swiftly to customer issues and requirements and offer prompt and effective solutions We aim to build long-term relationships with our customers and earn their Gas turbine wheel and respect by providing quality service