How It Fly In The Sky/Air :- Wow, that's so cool! One of the most important components in any jet engine design is a high-pressure turbine disc. The engine features a critical part buried deep as well tightens the atmosphere while sufficient power to get plane much higher, and that is recorded. This piece of aircraft is needed for planes to take-offs and land, so all over the world need to be able as fast -- go. This is the actually soul of a car, which really makes it works smoothly and in very good nature.

It is the high-pressure turbine disk, a very robust and well made part. This is actually designed to survive the abrasive conditions and hot temperatures inside a jet engine. Under full power, the engine puts a heavy load on those turbine blades and spins that disc really fast (more than 2,000 mph). That’s faster than most cars! In addition to being super hot, it copes with temperatures of up to 2000 degrees Fahrenheit! Most materials might completely melt or simply degrade at such temperatures, however the turbine is designed to continue spinning and generating electricity even in these harsh environs.

This High pressure Turbine Disc is mainly designed to allow the extraction of all power and full speed from jet engine its crack at this place destroys it for ever. The purpose of this item is to burn fuel which creates hot gases, these high temperature byproducts are aimed at producing energy as they move through a device that converts their heat into useful work. Mechanical energy that gives an airplane a push forwards through the air. It also the best part to convert energy from hot gases into mechanical one (as more power that can be released by engine). The more powerful the engine, it allows for increased range and speed of an aircraft.

Before they are airworthy and fit for duty, the turbine disc has to be tested in a few critical ways. The test involves running the equivalent of a turbine disc in an engine at extreme operating temperatures and pressures. In these tests powertrain engineers will gain a greater understanding of the stresses and strains on different components as well, allowing them to pinpoint areas that may need development for production refinement - in this case the turbine disc and some of its construction materials. After it has succeeded in all these, then the turbine disc can be called safe and is ready to use in an aeroplane.

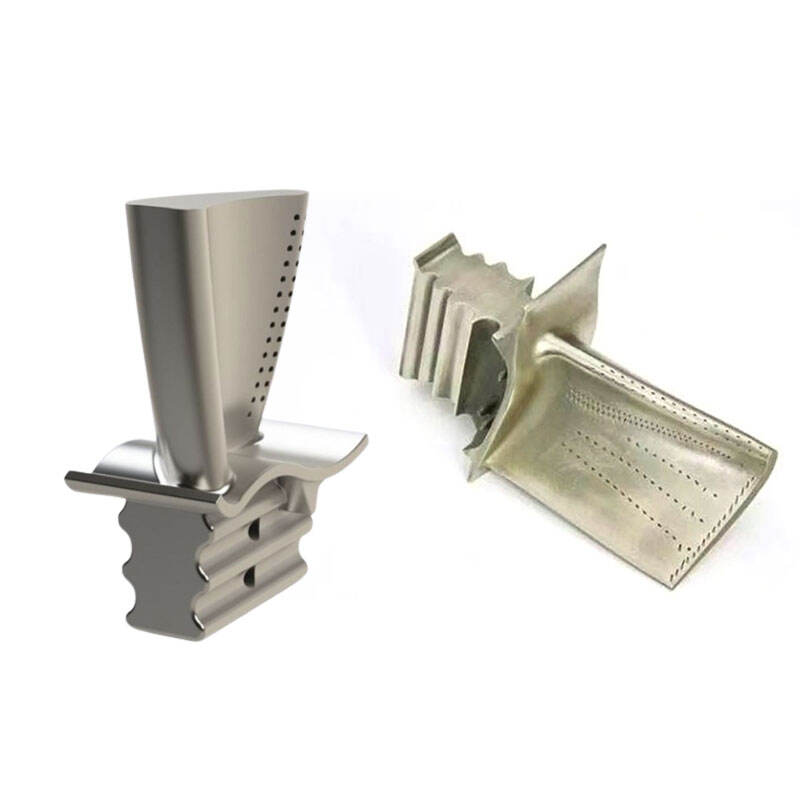

This is brought about by a sophisticated amalgamation of material and engineering in the high-pressure turbine disc. It's a disc with loads of tiny blades, each shaped and angled just right to do that job. They are made of special components that let them keep their robust and consistent form under high temperatures & pressures without warping or cracking. The design of being close to the limit here allows for high rotational speeds and extreme temperature resistance on paper by using expensive materials.

Our company follows strict high-pressure turbine disc standards in order to ensure excellent performance and dependability of each component. Quality control is conducted throughout the entire production process beginning with the purchase of raw materials through the test of the finished product. To ensure that the quality of our products is continuously improved, we perform regular audits and improvements. We strive to earn the trust of our clients and their long-term partnership by providing products of high-quality.

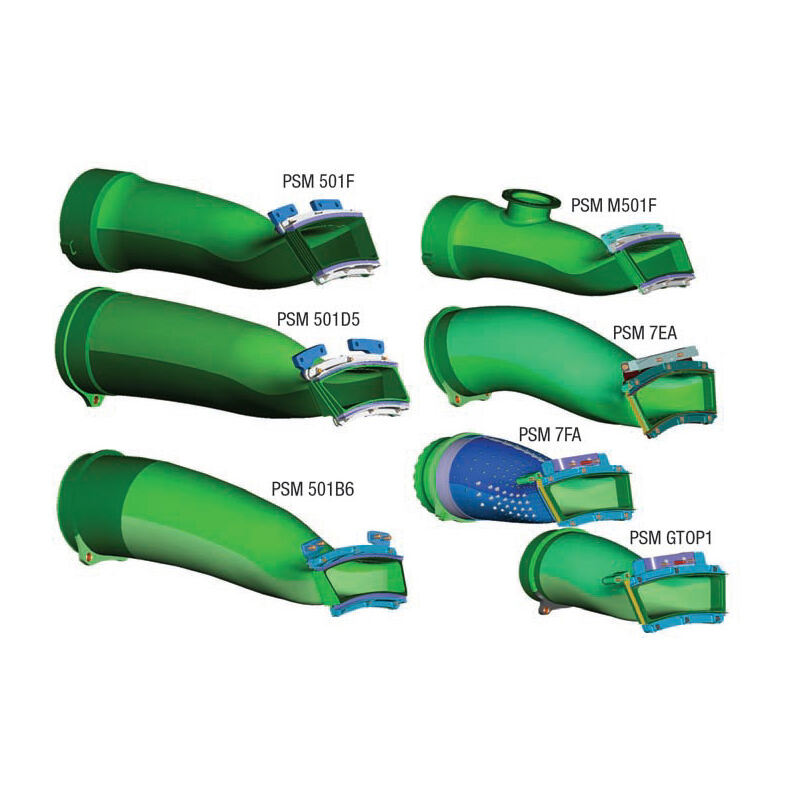

Our company offers a variety of customized services, and produces turbine components from an array of high-temperature high-pressure turbine disc to meet the requirements of our customers. Our flexible production process and advanced technology for processing and our ability to satisfy specific requirements, such as size shape, performance, or shape, allows us to achieve every need. We communicate closely with our customers in order to fully understand their individual requirements and situations and offer expert advice and solutions. We offer a wide range of materials and processing capabilities to meet the specific demands of various industries and applications. Through customized services, we help our customers optimize product performance and efficiency and increase competitiveness in the market.

Our customer support is high-pressure turbine disc and includes technical assistance, pre-sales advice and after-sales assistance to ensure our customers have the best possible experience. Our experienced team will review the needs of customers and offer the most effective solution and recommendations for the product. We provide technical support starting with the selection of products to installation and commissioning. This guarantees that our clients are able to enjoy our products without problems. We have a well-developed after-sales service that allows us to react quickly to customer requests and problems and provide quick and timely solutions. We strive to establish long-term relationships with our customers and earn their trust and respect by providing quality service.

Our company can fabricate highly precise and stable turbine parts through casting forging, and CNC machining. Casting allows us to create components with complex forms, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC technology for machining, on other hand, ensures high precision and consistency of every part, which reduces the chance of the chance of errors and producing substandard products. Our technical team that constantly carries the latest technological advancements and process improvement to make sure that our products are always at the top of the industry in terms of high-pressure turbine disc. We're determined to meet our customers' demands for high-performance turbine components through continuous technological advancement.