Ever wondered what makes room for a jet engine? It's a fascinating process! Rotor BladeOne of the critical components in a jet engine is Rotor blade. It is a little bit like the wings of birds on rotor blades. Much in the way that bird wings help a bird fly, or rotor blades assist the jet engineigarette run properly. These are spinning round and around at high speed to produce the power that allowS everything else in your engine TO WORK AS IT SHOULD.

The blades are strong but pliable. Which is why they are able to flex, a little bit before breaking. This flex is imperative because the rotor blades must be durable enough to endure the extreme heat and pressure present during operation of an engine. The blades are constructed out of very strong metals, such as titanium and steel to withstand those forces. The blades are also designed to function as curved wings, which is important so that the propeller can generate lift just like an airplane wing.

Having the ideal rotor blade takes many work in its layout. Highly accomplished engineers develop the optimal blade design for this process. For each blade, they have at their disposal expensive computers that help figure out the right shape and thickness. Su goal es: una cuchilla tanto fuerte como ligera. Lighter blades mean a faster-spinning engine, which sometimes allows the airplane to fly faster and burn less fuel.

Jet engines today stand as intricate machines containing a multitude of parts that come together to make everything work just right. The rotor blades are only one crucial aspect of this equation. They are linked to a long shaft which extends inside the engine full-length. On engine startup, rotor blades begin to rotate at extraordinary RPMs powering their way up. This is important power that assists the airplane in taking off which allows it to rise high into the sky.

Jet engines are practically perfect machines - they're designed to suck air in the front and blow it out the back with great force. To design engines more powerfull, less fuel and safer for everyone. To do so, a part of what they are realizing is by trying monstrously new materials for the rotor blades. This includes experimentation with carbon fiber (a material famed for its strength-to-weight ratio) They aim to improve the performance of their rotor blades using materials, like carbon fiber. Meanwhile, engineers are investigating how the air flows round those blades to come up with new tricks that might make them even more efficient.

Our company offers customized services, and can produce turbine components from an array of rotor blades in jet engine metals to meet the needs of customers. Our flexible production flow, advanced process technology, and our capacity to meet particular requirements, like size shape, performance, or shape can allow us to meet any requirement. We work closely with our clients to comprehend their needs specific to them and the application scenarios and provide professional advice and solutions. Our diverse selection of materials, processing capabilities and application-specific requirements allow us to meet the needs of a variety of industries and. With customized services, we help our customers optimize product performance and cost as well as increase market competitiveness.

Our company follows strict rotor blades in jet engine standards in order to ensure excellent performance and dependability of each component. Quality control is conducted throughout the entire production process beginning with the purchase of raw materials through the test of the finished product. To ensure that the quality of our products is continuously improved, we perform regular audits and improvements. We strive to earn the trust of our clients and their long-term partnership by providing products of high-quality.

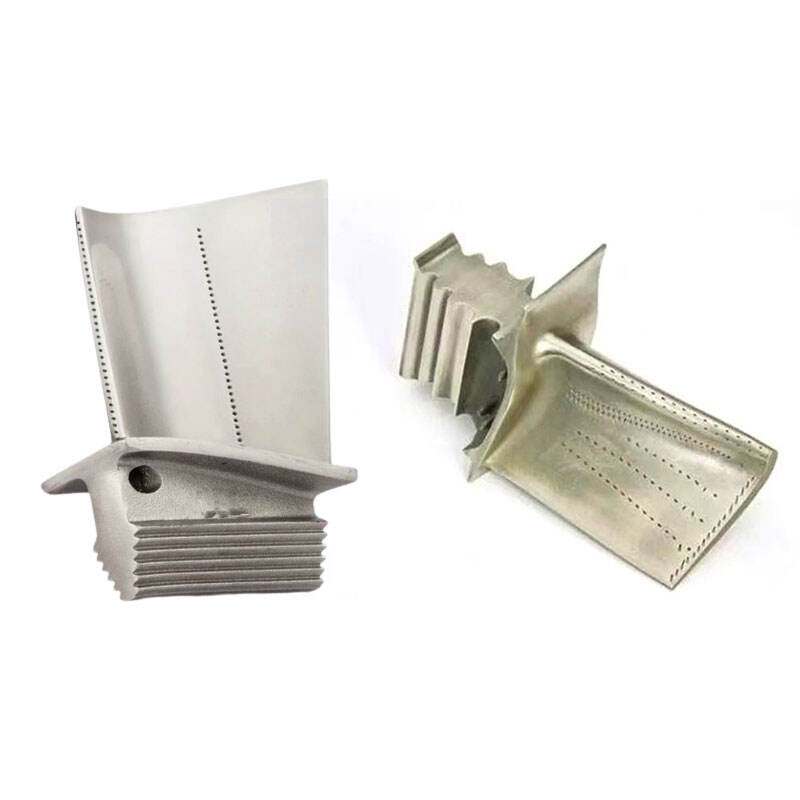

Our company is able produce highly accurate and consistent turbine parts by casting, forging, and CNC machining processes. The casting process allows us to produce parts with intricate shapes and strong durability, while the forging process gives the parts better rotor blades in jet engine and longer lasting. CNC machining technology, on the contrary, guarantees consistent and high-quality of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have a highly skilled technical team that constantly carries out technological innovations and process improvement to make sure that our products stay in the forefront of industry in terms of technological. We are committed to meeting the requirements of our customers for components that are high-performance by developing technology continually.

Our customer support is comprehensive and includesrotor blades in jet engine, technical support, and after-sales services to ensure that our customers get the best experience possible. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support starting with the selection of products to installation and commissioning. This ensures that our clients are able to use our products without any issues. We have a well-developed after-sales process that allows us to swiftly respond to issues and needs of customers, and to provide effective and prompt solutions. We are determined to develop long-term relationships with our clients and gain their trust and respect by offering high-quality services.