Rockets are incredible devices which literally fly high above the sky. They resemble mammoth, supercharged tubes blasting into the sky. Did you know rockets have different parts that help them get moving? A nozzle is one of the most critical components.

The rocket has a special tube at the bottom called a nozzle. This makes sure the rocket moves the right direction, going higher and higher. What helps shape the way the air comes out is the car with the straw we blow it. Rocket nozzles operate similarly, except they utilize very hot air!

When a rocket launches, a tremendous amount of power is needed to break free from Earth. The upper stage — the second stage of the rocket — has a specialized nozzle for more propulsion. That nozzle is super important because it makes the rocket reach all the way up to outer space. It’s like a super-powerful engine that gets the rocket flying.

The nozzle allows hot air to be released in a unique manner. The fast-moving hot gas acts like a blast of energy that propels the rocket ever onward. The shape of the nozzle is a big, big deal. A properly-shaped nozzle allows the rocket to travel farther and move more smoothly.

Scientists and engineers who build rockets are constantly devising new ways to improve nozzles. One group O.B.T is defying this by churning out excellent examples of nozzle designs. They create nozzles that are stretched out and skinny, allowing for easier passage of the rocket through the atmosphere.

To some, nozzles may be small beans and not seem to matter much. But that's not true! The Nozzles are extremely important to the thrust of the rockets to flying to Space! They help scientists discover fresh insights into our grand, fascinating universe. And without these special nozzles, rockets could not fly very far.

The nozzle, by the way, has to really do some work to push a rocket higher and higher each launch. It’s basically a super helper that makes the rocket can go on space adventures. Rocket scientists never stop learning, and they work to improve these nozzles even further.

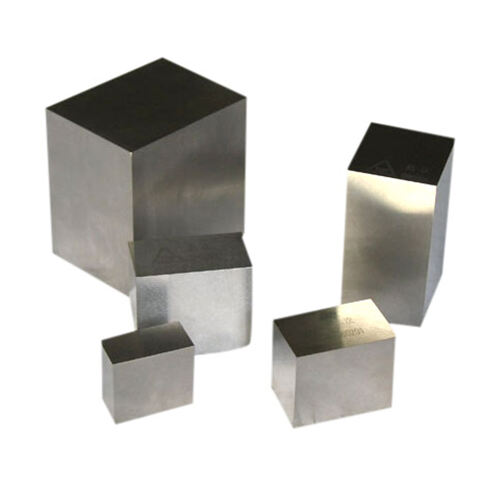

Our company offers a variety of custom-designed services and is able to manufacture turbine parts from various high-temperature alloys to meet the requirements of our customers. Our second stage nozzle along with our advanced process technology and our capability to meet specific requirements, such as size shape, performance, or shape can allow us to meet every need. We work closely with our customers to understand their specific needs and application situations and offer expert technical guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements to the application allow us meet the requirements of various industries and application. With our customized services, we assist our customers in optimizing their the performance of their products and reduce costs, and improve market competitiveness.

Our complete customer service package includes pre-sales consultation technical support and after-sales assistance to ensure our customers have the best possible experience When it comes to the pre-sales phase our experienced team will understand the customer's needs in detail and provide the most suitable suggestions and solutions In terms of technical support we offer full guidance from product selection until installation and commissioning to ensure that our customers use our products efficiently When it comes to after-sales service we have developed an second stage nozzle service system that can respond swiftly to customer issues as well as needs and provide quick and effective solutions We want to create long-lasting relationships with our customers and gain their trust and appreciation by offering high-quality services

Our company is committed to strict quality control standards to guarantee the best performance and reliability of every component Every step of the production process is controlled for quality starting from the purchase of raw materials all the way to the final test of the product We also carry out regular quality audits as well as adjustments to ensure constant improvements in product quality Our goal is to win the trust and continue to work with of our clients by offering top quality products and to become an second stage nozzle

We are able to create turbine components with high accuracy and consistent quality through CNC machining, casting and forging processes. Casting allows us to create parts with complex shapes, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC second stage nozzle technology, on other hand, ensures the highest precision and accuracy of each piece, minimizing mistakes and ensuring that the product is of a high standard. Our highly skilled technical team is continuously developing technological advancements and process optimizations in order to keep our products at the cutting-edge of technology in the industry. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continuously.