Have you ever seen those big machines that generates electricity in a power plant, or the massive engines used to keep planes flying high in the air? May Look _____ But these machines you face one very critical aspect called: turbine blade. These buckets are also critical to making sure the machines are functioning well and performing their respective jobs.

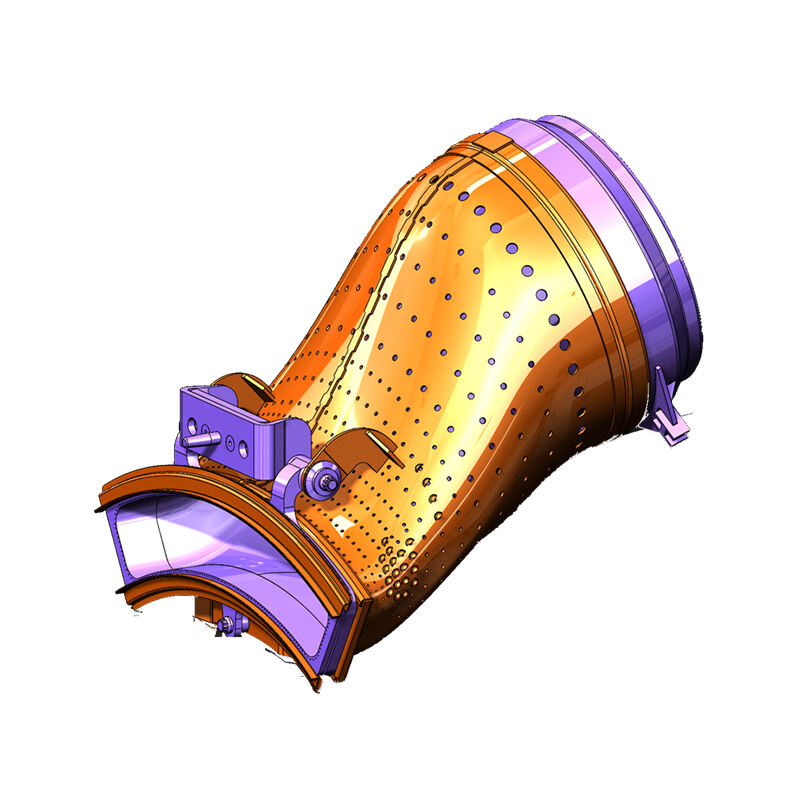

1st stage buckets are alternatively known as rotor blades. You can think of them like the blades of a turbine or engine.” They are molded to be an arc and can turn at high rates of speed. This spinning is essential to generating power or lifting heavy things up. The shape of 1st stage buckets and angle at which they are placed are critical as well. They must operate in complexities, so they drive the maximum performance from the machine.

Since, 1st stage bucket is inappropriate, this may also have problems like turbulence. That means that it contains turbulent air, which can cause the turbine to work less efficiently. That means it’s not going to work as well as it is designed to work.” The 1st stage bucket design is too important, but if the design of the 1st stages bucket is just right, then it can really push the air in easily, thus it can help the turbine working better and easier.

Like all thing in scratching; different machines require different types of second stage turbine blade. The 1st stage bucket size, shape and material is dependent on several factors. These are the type of fluid handled by the machine, the working temperature, its operational speed, and the pressure the machine is exposed to.

As an example, the 1st stage buckets of a gas turbine must handle high temperature and high pressure, requiring materials that can tolerate these conditions well. The reason is that gas turbines get hot in operation. But on actual steam turbine, the 1st stage buckets needs to be designed to deal with very high moisture content in steam. That means they need to be built from materials that can withstand the corrosive wear of the steam.

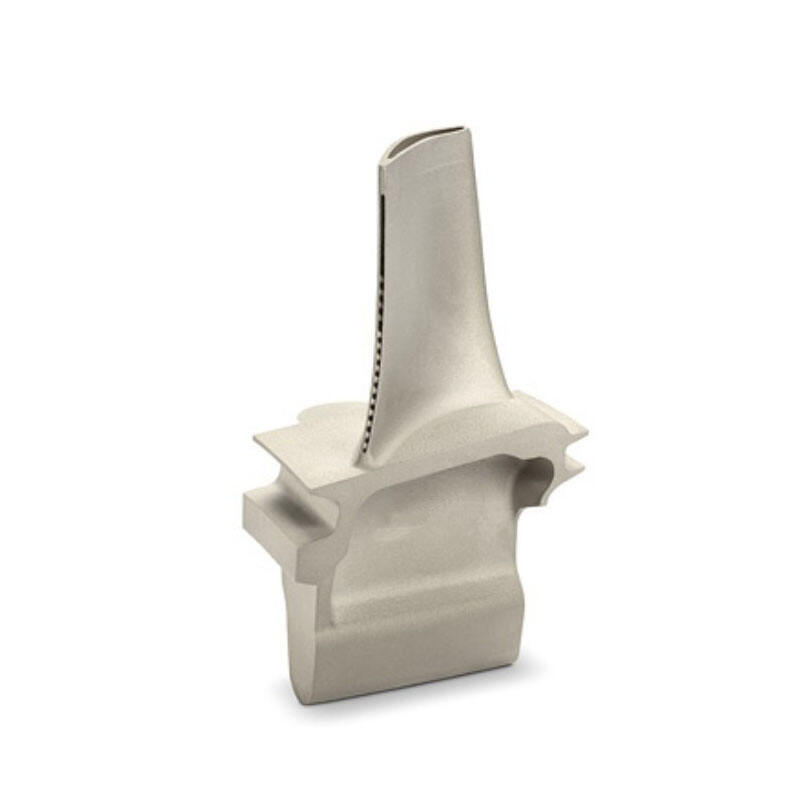

Moreover, engineers even use cutting-edge technologies such as 3D printing to create physical models of the 1st stage bucket. Then, they can try out the bucket in real scenarios to see how well it performs. These tools let engineers analyze and optimize the design of the 1st stage bucket. They want to make it work as efficiently as they can and to allow the machine to perform the best it can.

Over the years, billions of dollars in operations have been spent on their 1st stage bucket technology to help thousands of businesses operate more efficiently. For example, company gas turbine 1st stage buckets have enabled power plants to generate higher output for lower fuel burn. This is important because they can save money and make better use of resources.

Our company is committed to strict quality control standards to guarantee the best performance and reliability of every component Every step of the production process is controlled for quality starting from the purchase of raw materials all the way to the final test of the product We also carry out regular quality audits as well as adjustments to ensure constant improvements in product quality Our goal is to win the trust and continue to work with of our clients by offering top quality products and to become an 1st stage buckets

Our company provides specific services that is able to manufacture turbine parts from an array of high-temperature metals to meet customer needs. If it's a particular shape, size or performance requirement, we are able to meet it using our flexible production process and the latest process technology. We stay in close contact with our clients to comprehend their individual requirements and scenarios, and provide them with expert technical guidance and solutions. We have a broad range of materials and processing capabilities to meet the unique needs of various industries and applications. Our clients can improve their 1st stage buckets by providing specific services that maximize performance and reduce costs.

We offer a comprehensive customer service that includes pre-sales consultation as well as technical support and after-sales assistance so that our customers have the most pleasant experience In the pre-sales stage our experienced team will understand the customer's needs in detail and provide the most appropriate suggestions for products and solutions For technical support we offer full guidance from product selection to installation and commissioning to ensure that our customers use our products with ease We have developed an after-sales program that enables us to quickly respond to customer concerns and issues and to provide effective and timely solutions We are determined to develop long-term relationships with our clients and 1st stage buckets their trust and satisfaction through offering high-quality services

Our company has the ability to produce highly accurate and consistent turbine components by using casting, forging and CNC 1st stage buckets. The casting process permits us to produce parts with complex shapes and high strength, whereas the forging process gives the parts better mechanical properties and longer lasting. CNC machine technology, on the contrary, guarantees an extremely high level of precision and consistency in each component, thus reducing the risk of errors and substandard products. Our skilled technical team is always striving to improve technological innovation and process improvements in order to ensure our products are at the cutting-edge of technology in the industry. We're committed to meeting our customers' needs for turbine components that are high-performance through constant technological advancement.