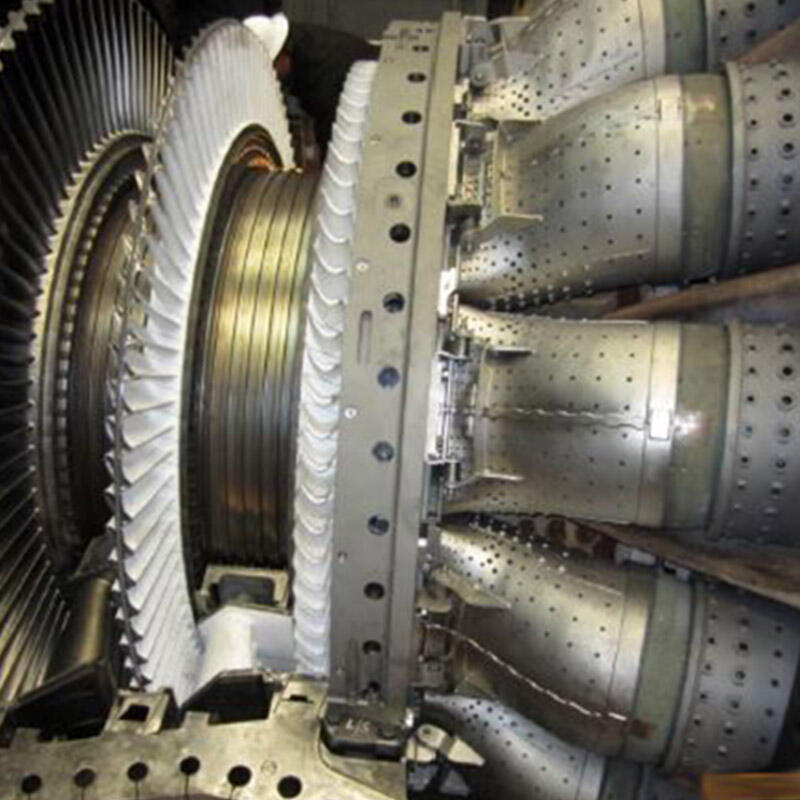

The next process of creating the stream and when it is generated, then we will send that steam in a machine which call steam turbine. A steam turbine is composed its various parts and one of them is a diffuser. The work of a steam turbine diffuser is important as it allows moire energy to be extracted form the steam,creatin g more electricity. In this article, we will learn about the importance of a good steam turbine diffuser when it comes to creating electricity efficiently.

Well get back to what makes a good steam turbine diffuser in just one moment, but first we need to know about the diffusion component itself. A diffuser is a component that works to reduce the speed of steam exiting from turbine blades. As the steam slows down, it loses some pressure and energy. A well-engineered diffuser takes care of the slowing down, and ensures that this steam does so in such a way as to give up its full energy content.

Firstly, an efficiently designed steam turbine diffuser is important for the effective operation of a Steam Turbine. As the steam emerges from diffuser section it gets its pressure reduced and in turn a vacuum effect takes place. Because this vacuum sucks more steam past the turbine, we get to make even more electricity However, without a good diffuser this causes the steam to move around so much which makes turbulence. This turbulence can be wasteful and not all energy is converted into electricity.

Now, let's get a bit deeper in the rematch and understand how this actually works for steam turbine diffuser. Changes the contour of which the steam travels through The steam slows as the path widens and flattens out a little The slower steam helps create a vacuum, which improves the efficiency by pulling more steam through the turbine blades. Pulling additional steam through it allows the diffuser to remove more energy from it, which then results in a greater amount of electrical power output.

A steam turbine diffuser can also have the help of a contraption called convergent-divergent nozzle. The main function of this nozzle is to produce a high-velocity steam jet. As this jet of steam strikes the turbine blades it makes them rotate generator (alternator) together with some doable damage to your choppers. In addition, the nozzle forms a low-pressure area immediately behind it which serves to draw even more steam through the blades contributing positively in extraction energy.

Steam Turbine Diffuser DesignThe Steam turbine diffuser design is the main part of steam turbines, while installing engineers has to concentrate on shaping it. Importance of the diffuser shape: The next critical aspect in any best travel steamer is its ability to allow steam through it and here also, the funnel shaped diffusers reign supreme. The diffuser size is directly proportional to that of the steam turbine with which it was originally designed. The diffuser material should also be able to resist the high temperatures and pressures of the steam itself.

Key BenefitsOne of the advantages to a personalized diffuser part is better energy require High efficiency, built where it will make one of several major key point replacement for A essential way of thinking was essentially upgrades at buying selling price and / or higher electricSqlCommand.ExecuteNonQueryion billenment savings. Furthermore, a tailor-made diffuser can reduce downtime and the costs associated with maintenance making it possible to use your power plant for more hours without any interruptions.

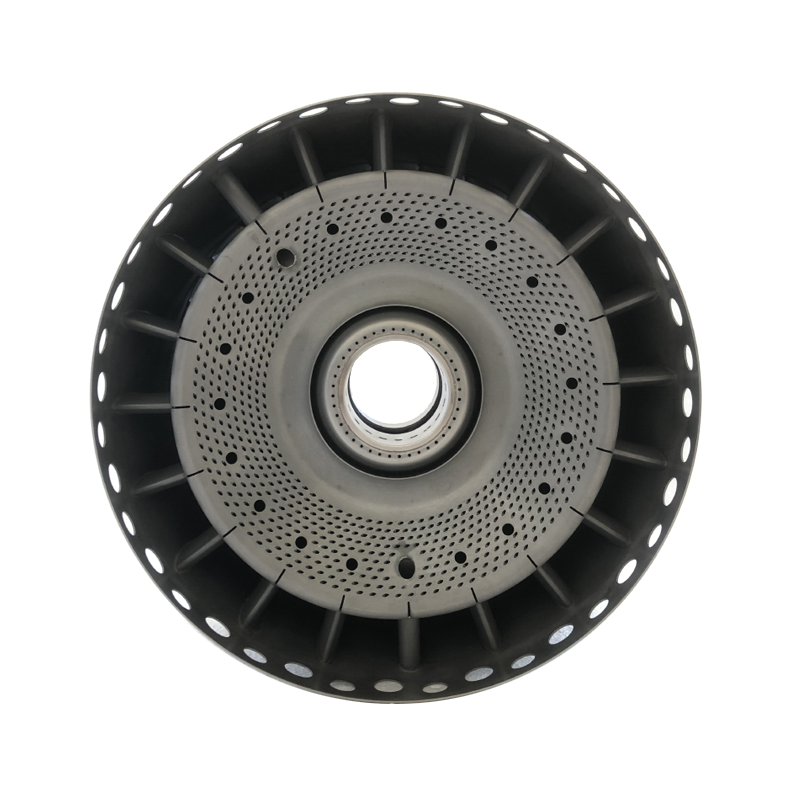

Our company is able produce highly accurate and consistent turbine parts by casting, forging, and CNC machining processes. The casting process allows us to produce parts with intricate shapes and strong durability, while the forging process gives the parts better steam turbine diffuser and longer lasting. CNC machining technology, on the contrary, guarantees consistent and high-quality of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have a highly skilled technical team that constantly carries out technological innovations and process improvement to make sure that our products stay in the forefront of industry in terms of technological. We are committed to meeting the requirements of our customers for components that are high-performance by developing technology continually.

Our customer support is comprehensive and includes technical assistance, steam turbine diffuser and after-sales assistance to ensure that our customers get the best possible experience. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support throughout the entire process, from choosing products, to the installation and commissioning. This guarantees that our customers can make use of our products with no issues. We have developed an after-sales service that allows us to quickly respond to customer requests and problems and provide efficient and timely solutions. Our goal is to establish lasting relationships with our customers and gain their confidence and satisfaction with quality customer service.

Our company is committed to strict quality control guidelines to ensure the highest quality and reliability of every component Quality control is conducted throughout the entire manufacturing process from the purchase of steam turbine diffuser to the test of the finished product We also perform regular quality audits and improvements to ensure continuous improvement in the quality of our products Our aim is to earn the trust and long-term cooperation of our clients by offering quality products that are of the highest standard and to be a leader in the industry

Our company offers customized services, and can produce turbine components from an array of steam turbine diffuser metals to meet the needs of customers. Our flexible production flow, advanced process technology, and our capacity to meet particular requirements, like size shape, performance, or shape can allow us to meet any requirement. We work closely with our clients to comprehend their needs specific to them and the application scenarios and provide professional advice and solutions. Our diverse selection of materials, processing capabilities and application-specific requirements allow us to meet the needs of a variety of industries and. With customized services, we help our customers optimize product performance and cost as well as increase market competitiveness.