The principle of action - an impeller compressor is a specific machine that produces gases or air by pressing the flow. This causes them to using air and compact it into a limited region. It makes the atmosphere easy to control and assists in numerous ways. From inside our homes to factories where things are made, these machines should be evident everywhere.

Featuring a high energy efficiency One of the best parts about impeller compressors is their nature to use very low amounts of power. This is crucial because it keeps things cool well with lesser energy consumed and thus costs less. Not only will you be saving your money and wallet, but also helping to maintain a greener planet by reducing pollution.

How Impeller Compressors Help HVAC SystemsWhile not even in the least bit an "expansion" to especially imaginative group of followers, impellers are utilized locally and industrially since they make existing systems work better while making things more secure for members. These systems reduce the energy used by other components, so they can heat or cool air as needed without consuming a lot of power. Which is important to keep us comfortable all year!

Finally, they use less energy the other type of compressors and this means that thereon fewer harmful gases will be released into our air. These gases are harmful to the environment. We are helping the environment by reducing them and in turn doing our part to keep this planet healthy for many years down the line. We are just contributing but still hey, it is saving the planet!

Delivering quicker results is possible with a set of impeller compressors, redefining the nature manufacturers and workers work on their project. They make it simpler to transport materials and power factory-required machines. This, if nothing else hastens things up so a win in my books all round!

Some of the improvements are in the fact that they can now make them smaller and easier to use different places. This will enable more people to purchase and use these compressors in a better way. This miniature size also reduces storage space and makes them a good already suited to being inserted into various other gadgets or applications.

Using better materials in each of these machines is another way to improve them. Using improved and more resilient materials, researchers are able to achieve compressors capable of nearly double the pressure capacity that last for an extended duration. This allows for an even wider set of use cases without relying on it failing.

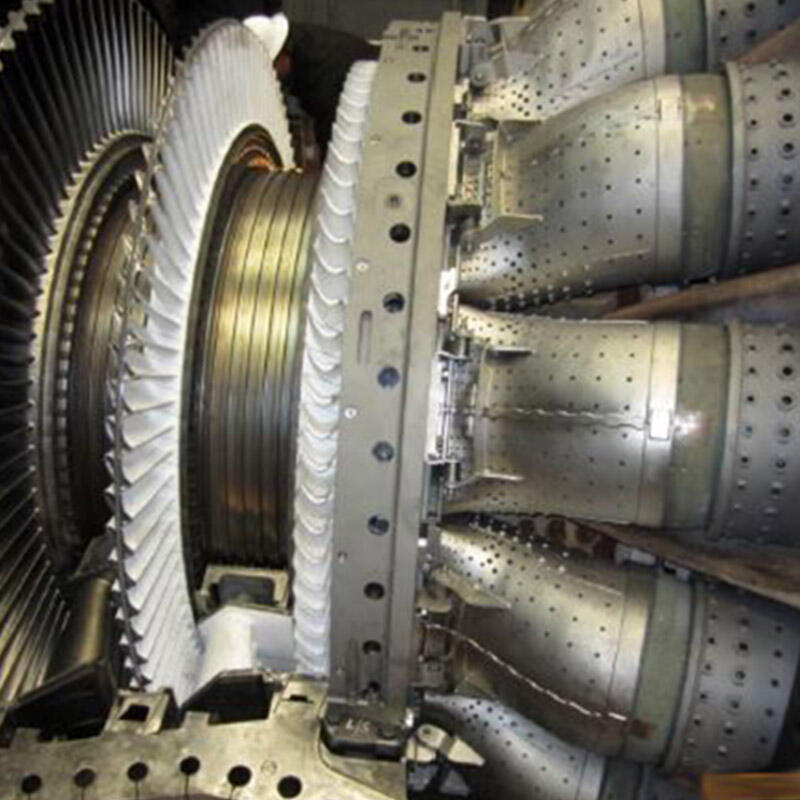

We are able to create turbine components with high accuracy and consistent quality through CNC machining, casting and forging processes. Casting allows us to create parts with complex shapes, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC impeller compressor technology, on other hand, ensures the highest precision and accuracy of each piece, minimizing mistakes and ensuring that the product is of a high standard. Our highly skilled technical team is continuously developing technological advancements and process optimizations in order to keep our products at the cutting-edge of technology in the industry. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continuously.

Our comprehensive customer service includes pre-sales consulting technical support and after-sales services to ensure that customers enjoy the most enjoyable experience Our expert team will assess the needs of customers and offer appropriate product suggestions and solutions We provide technical support starting with the selection of products through installation and commissioning This ensures that our customers are able to enjoy our products without issues For after-sales support we have developed an efficient service system that can respond swiftly to customer issues as well as needs and provide impeller compressor and efficient solutions Our goal is to create long-term relationships and gain customers trust and their satisfaction by providing superior customer service

Our company offers customized services and is able to fabricate turbine components from many different high temperature alloys based on customer specifications. Our flexible production flow along with our advanced process technology and our capability to meet impeller compressor, such as size and shape, as well as performance can allow us to meet any requirement. We work closely with clients to comprehend their needs and the potential scenarios for their applications, and then give them professional guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements for applications allow us to fulfill the particular requirements of various industries and application. With our customized services, we help our customers optimize efficiency and costs of their products, and improve market competitiveness.

Our company is committed to strict quality control guidelines to ensure the highest quality and reliability of every component Quality control is conducted throughout the entire manufacturing process from the purchase of impeller compressor to the test of the finished product We also perform regular quality audits and improvements to ensure continuous improvement in the quality of our products Our aim is to earn the trust and long-term cooperation of our clients by offering quality products that are of the highest standard and to be a leader in the industry