Steam turbine stator is a prime part of power plant designing, making electricity. An electricity plant will not be able to produce the power that supplies homes, businesses inj cities if a stator is offline. STATOR FOR STEAM TURBINE WITH LOTS OF PIECES PARTSWe need to be able invested in the coil-slot data mapping software of a steam turbine stator - an assembly made up many, many individual components each working together. A stator consists of number of components and they each have their own task to perform,when put together it allows us produce current which leads in making electricity.

This is some of the energy out of that rotor and they put it to use, or at least a portion in our stator right here: their job being electricity for all mankind. The extreme iron center revolves around the stator, with a coil of wire wrapped in twine. During rotor rotation inside of the stator, a powerful magnetic field is created. When we put it in coil of wire, this will create the tiny particles — which are electrons that flow inside. When such charge is in motion, it produces an electric current. The next step is that this energy current is sent out to pretend as a generator, which transforms this right into functional power in order for your lights tools plus thousands of even more things in the both residential houses and firms can be powered up wholedonkey

Steam turbine stators are built to last a long time, but they must be maintained regularly if you want them do well on the job. Similar to how a car needs changes every once in and awhile, this is what STEAM TURBINE STATOR MAINTENANCE does for your steam turbines. If properly maintained the excelerotor can help to prevent some of this such as it rusting out and becoming brittle or curing. Additionally, if these symptoms appear; they can also be very challenging to fix — and it comes with a high price tag. Cleaning the stator should be a regular thing, but making it part of your routine inspection can help you catch potential problem areas early enough to make small changes that will prevent them from becoming much larger problems in the future. But they need the craftsmen to take care of them and make sure that they are still around. So they just keep producing electricity for decades like this saving all us people from having the power go out.

If you want to have more reliable and consistent power then knowing how the steam turbine stator works is crucial. The stator acts as a dynamo, rather like an extended colossal magnet spinning relative to the rotor. When the rotor turns that takes a magnetic field with it and this acts on its stator. Those would be copper wire coils that have been arranged around the stator in a precise fashion. This coils are responsible to transforming the magnetic field into usable electricity. After the power is created, it passes through a generator that exits into an outlet enable to be used of houses and stores in homes. This will make sure our electricity is always on board for everyone if we keep learning how a steam turbine stator works.

Technological advances have developments these steam turbine stators and so they come with enhanced efficiency. There's also added toughness in the form of new materials for constructing wire coils, as well as more high-temperature performance. Such improvements are critical for better, more reliable electric power generation is crucial to the security of electricity supply. In addition, new design tasks have been carried out to close the gaps between rotor and stator blades. Closing these gaps reduces energy loss that increases efficiency of power plant as a whole. With the development of technology, we can expect much brighter future awaiting steam turbine stator. In the end this can make them gadget greater power efficient and greener for our destiny.

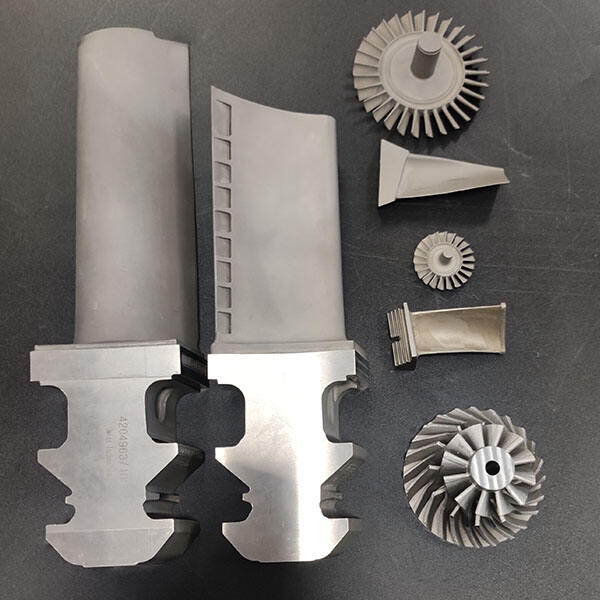

We are able of producing turbine components with high accuracy and consistency through CNC machining, casting and forging processes. The casting process permits us to create parts with intricate shapes and strong strength, while the process of forging provides parts higher mechanical properties and longer lasting. CNC machining, on the contrary it provides superior precision and consistent quality for every part. This reduces errors and lower quality products. Our skilled technical team is always working on technological innovations and process optimizations in order to steam turbine stator that our products remain at cutting-edge of technology in the industry. Our goal is to satisfy the needs of our customers for high-performance parts by constantly advancing technology continuously.

Our complete customer service package includes technical assistance pre-sales advice and after-sales assistance to ensure that our customers receive the best experience possible At the time of pre-sales our team of experts will be able to understand the needs of the customer in detail and provide the most appropriate product suggestions and solutions We offer technical assistance from the selection of products through installing and commissioning This guarantees that our customers are steam turbine stator to use our products without any issues We have a well-developed after-sales system that allows us to respond quickly to customer concerns and issues and provide efficient and prompt solutions We aim to build long-term relationships with our clients and earn their trust and satisfaction by providing quality service

Our company offers custom-designed services and can make steam turbine stator in an array of high-temperature alloys in accordance with customer specifications. Whether it is a specific dimension, shape or requirements for performance, we can accomplish it by using our flexible production process and cutting-edge process technology. We collaborate closely with our customers to comprehend their needs as well as the various scenarios they might encounter and then offer them expert assistance and suggestions. Our diverse selection of materials processing capabilities, processing capabilities as well as specific requirements to the application allow us satisfy the specific needs of various industries and application. With customized services, we help our customers optimize the performance of their products and reduce costs, and improve market competitiveness.

Our company follows strict quality control standards to guarantee the best performance and dependability of each component The entire steam turbine stator is monitored for quality starting from the purchase of raw materials all the way to the final test of the final product To ensure that the quality of our products is continually improved we regularly conduct audits and adjustments Our aim is to earn the trust and continue to work with of our customers by providing top-quality products and becoming an industry leader