There are machines tailor-built to capture the energy within moving such as water, steam or gas: turbines. They are used to fuel many things such as causing the environment run or making power for our homes and cities. A turbine blade is one of the important segments in a turbine. A Blade: Each blade is like a propeller on an airplane-it helps the turbine accomplish its job. It resembles a small wing and is built with high-strength metal materials. They have a special way of making these turbine blades, it is called precision casting so that they are made very precisely just like in CNC.

When we say that, it means you have to spend money on something and expect for the return in future is actually how investment works. Companies who opt for trade in construction of turbine blade casting invest in the right direction as it helps to save a good amount of money over time. O.B.T turbine blade manufactured with investment casting are designed to perform more effectively. This allows them to use less fuel to produce more power, an advantage for both the company and nature.

Turbine blade casting is an investment for many good reasons. For one, it saves you a lot of money. This is because the blades can be manufactured more precisely and with less wastage. That they are better for the planet, too. Secondly, it speeds up the time of creating blades (which in turn makes other companies more efficient as well). The third point is: investing in to O.B.T single crystal turbine blade casting past the saving energy. The less energy the blades use to be efficient, better work. This type of investment finally offers industry the possibility to design complex and challenging shapes, such as my example with turbine blades. This makes it possible to construct more efficient blades based on the work that needs doing.

This is a specific and exciting metal object development technology known as investment casting. All starts from making a wax shape of the object we need. The wax shape is then encased in a ceramic material that sets. Beyond dipping the object into an 18 inch deep vat of raw ceramic, as we will discuss below. After curing and hardening comes dewaxing; after which you are left with a mold. This mold is subsequently subjected to hot, molten metal and when this metal cools down it solidifies in the required form. One of the best ways to make extraordinarily fine and exact metal things.

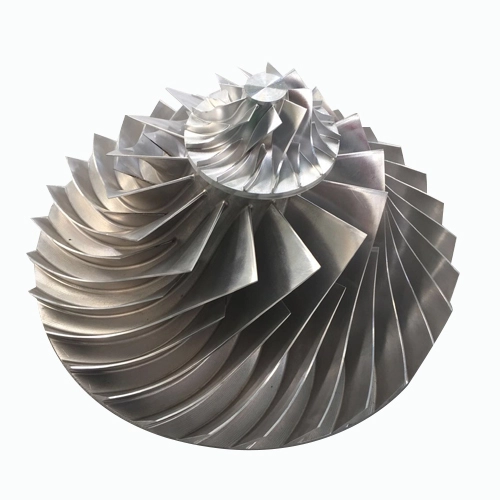

Investment casting is an established method of producing turbine blades that leads to high-quality parts. These items have a sleek surface to allow them glide through the air or water with minimal resistance. In addition, this smooth surface is free of the cracks and bubbles that can create weak points in a blade leading to breakage. O.B.T impeller investment casting is employed to produce intricate shapes that do more efficient work-turbine blades can better be made the turbine blade, in other words.

Our company offers customized services and is able to fabricate turbine components from many different high temperature alloys based on customer specifications. Our flexible production flow along with our advanced process technology and our capability to meet Turbine blade investment casting, such as size and shape, as well as performance can allow us to meet any requirement. We work closely with clients to comprehend their needs and the potential scenarios for their applications, and then give them professional guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements for applications allow us to fulfill the particular requirements of various industries and application. With our customized services, we help our customers optimize efficiency and costs of their products, and improve market competitiveness.

We follow Turbine blade investment casting for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.

Our company has the ability to create highly precise and reliable turbine parts through casting Turbine blade investment casting, and CNC machining processes. Casting allows us create components with complex designs, strong and long-lasting. Forging provides parts with a better mechanical quality and longer durability. CNC machining, on the contrary offers high precision and consistency for every component. This reduces errors and inferior products. Our technical staff is constantly developing technological advancements and process improvements to ensure our products are at the forefront of industry technology. We're committed to meeting our customers' demands for high-performance turbine components by continual technological advancement.

We provide a Turbine blade investment casting, including pre-sales consultation as well as technical support and after-sales services to ensure that our customers enjoy the most enjoyable experience. Our expert team will assess the needs of customers and offer appropriate products and solutions. Concerning technical assistance, we provide all the guidance needed from choosing a product to installation and commissioning to ensure that customers can use our products without difficulty. In terms of after-sales service we have designed a flawless service system to react quickly to customer concerns as well as needs, and provide quick and effective solutions. Our goal is to develop long-term relationships, and gain customers trust and satisfaction through superior customer service.