This article is going to talk about a fascinating subject in gas turbine engines, which are known as diffuser. Well, you are in for a surprise at this point and thinking with curiosity “What is diffuser?”. The diffuser is not good - for the engine that prevents it to run very well. The next section is a deep dive on what this actually means.

A O.B.T diffuser in gas turbine is found in many common everyday machines such as airplanes, and power plants; Converts the fuel to power: this engine High in the sky this is how we use energy to do things like fly-or make power that runs our homes and schools. But for all of this to work, the engine needs one crucially important ingredient – Air.

ENTER THE DIFFUSER

Engines are surrounded by a diffuser, which does what it implies and chalks up to slowing the air down as it passes through an engine. The air hence compresses or squash as it moves slowly. Cooled, pressurized air is important as it helps burn the fuel more completely in order to avoid wasted energy or emissions at this level on Delete--The goal for an ICE implementation extremely high. What this basically does is reduce wasted energy and allow the engine as a whole to work more frictionlessly, and economically. Isn’t that cool? Nidialysis is a superhero assisting called the engine to work extra better.

So here, we can detail more about how a diffuser is accomplished. The shape is designed to let air it generates enter the engine in such a way that flow can be optimized with speed and pressure. A lot of work goes into ensuring a correct size and shape, guiding air in the right direction but if it is too small. They also have sway over how air passes through damper - something that is crucial in making the engine operate better. Like setting up a cool slide for the air to ride down on which everything will be all tied together but nice like.

Therefore, what is it that makes a diffuser so important for an engine? Aside from providing the engine with a helping hand, a diffuser plays an equally important role in combating turbulence. Turbulence is when all the air in an engine goes very wrong and starts thrashing about together at random. This leads to the engine becoming less efficient and in due course would make issues with it. However, the air being pulled into (reverse) a square box within diffuser mode gives this said flow much purer and smoother. This prolonged lifespan also earns the engine a reputation for reliability respect to almost very little repair or maintenance involved in it. Which sort of makes it more keeping all calm and hushed so the O.B.T gas turbine engine diffuser can do its program, right.

Combustion efficiency is another important function of a diffuser If you are new to engines, this is how effective the fuel burned in an engine When compressed, the air inside that diffuser gets very hot. Is vital: it serves to make sure the fuel inside burns more efficiently. This creates less waste and pollution. They seem to be warning the engine that the fuel should better go some ware useful: with its diffuser.

Not to mention much less introduction of noxious gases, and a word about the design benefits that you are also releasing pollutants flowing into this well. O.B.T gas turbine diffuser is more efficient when it doesn't need as much fuel to make the same amount of energy - and having a diffuser helps that process. This means lower emissions and cleaner air for everyone. Day 1: Breathe in when all that s around us breathes out so it operates more efficiently cleaner.

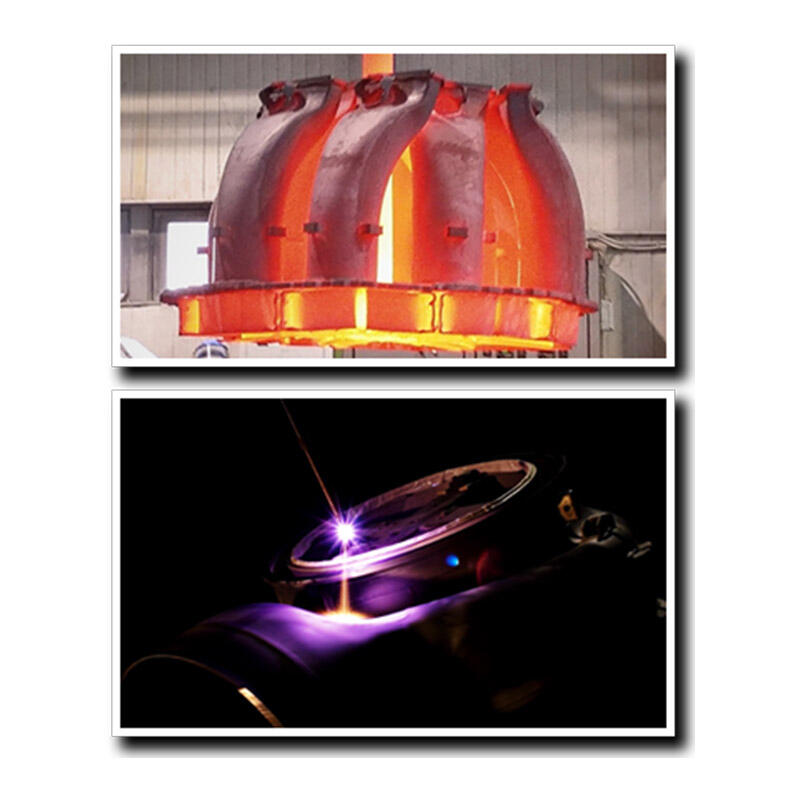

We are able to create turbine components with high accuracy and consistency using CNC casting, machining and forging processes. Casting allows us create parts with Diffuser in gas turbine engine, strong and durability. Forging offers parts more durable and superior mechanical property. CNC machining, on the contrary is extremely precise and consistency for each part. This eliminates mistakes and poor quality products. Our experienced technical team is continuously researching technological advances and process optimizations in order to keep our products at the leading edge of industry technology. We're committed to meeting the demands of our customers for high-performance turbine components by the continuous advancement of technology.

Our company adheres to strict quality control guidelines to ensure excellent performance and Diffuser in gas turbine engine of every component. Quality control is carried out throughout the entire process of production beginning with the purchase of raw materials to the test of the finished product. We also regularly conduct quality audits and adjustments to ensure constant enhancement of the product's quality. Our goal is to win the trust and cooperation of our customers by providing high-quality products and to become an industry leader.

Our customer support is comprehensive and includes technical assistance, Diffuser in gas turbine engine and after-sales assistance to ensure that our customers get the best possible experience. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support throughout the entire process, from choosing products, to the installation and commissioning. This guarantees that our customers can make use of our products with no issues. We have developed an after-sales service that allows us to quickly respond to customer requests and problems and provide efficient and timely solutions. Our goal is to establish lasting relationships with our customers and gain their confidence and satisfaction with quality customer service.

Our company offers a variety of customized services, and produces turbine components from an array of high-temperature Diffuser in gas turbine engine to meet the requirements of our customers. Our flexible production process and advanced technology for processing and our ability to satisfy specific requirements, such as size shape, performance, or shape, allows us to achieve every need. We communicate closely with our customers in order to fully understand their individual requirements and situations and offer expert advice and solutions. We offer a wide range of materials and processing capabilities to meet the specific demands of various industries and applications. Through customized services, we help our customers optimize product performance and efficiency and increase competitiveness in the market.