Consider the idea of how aeroplanes fly at such high altitudes in the sky! It’s really fascinating! In large jet engines, these behemoths are fed a healthy spray of Ram-Air down both inlets from our first trick you can't see under the cowling. In layman's term-a jet engine is a fan. It takes air at the in front and makes it go out through back with such velocity that provides sufficient force to raise plane up from ground. However the engine works and there are so many components insidewhich is why it requires a range of elements that work together in harmony from milder products createdin this unique fan blade: organs, muscles... tissues.

For example, what appears to be fan blades and is indeed a jet engine blade. However, the truth is that they are very special and sophisticated vehicles. In addition to their load-handling capacity, they are spinning faster than most engines can crank and need the ability to handle conditions of extreme heat, pressure air from inside a high-speed rotating object. These blades are not arbitrary in shape and size - all based on many leading factors: blade speed, the atmosphere mass flow, or the engine's run mileage. Those are not just numbers that can be plucked out of the air. Engineers who can employ specialized computer programs must then provide clues as to how these blades will work in the various conditions, known as operating states. Once they are confident the blades can get into flight, they begin to adjust and revise them.

You can also view making those blades inside jet engine is an art form, fills with talents and so much hard work. These blades are often made of strong, lightweight materials like titanium or certain specialized metals. They begin the process where they melt that metal. In its unctuous form it is drawn out into long strings. Then, using very high-tech blade separating and shaping tools that can do this accurately. They need every blade to be individually designed and handcrafted, polished so smoothly it fits like a kiss inside the heart of an engine that experiences stresses high enough they only narrowly avoid ripping apart at supersonic flight. Common to all is a painstaking process of tailoring the blades to perform their task safely and efficiently.

In reality, jet engine technology is constantly evolving. Airplanes are a subject near and dear to the heart of engineers - in general as well as of aircraft designers, who continuously seek greater speed (and its corollary better fuel economy) not too mention reliability. In recent years, scientists have experimented with other materials like carbon fiber to make a jet engine blade that is stronger and lighter than the one used in older model engines. Tested by his engineers, 3D printed prototypes are also being explored in practice allowing them to create shapes that might otherwise be un-achievable with traditional methods. Those new ideas, provided they work have the potential to make flying more efficient and safer in decades decade.

The blades of a jet engine, no matter how well-designed they are, will eventually fatigue under the hardest set of working conditions any heavily-used aircraft can handle. So, it is important to keep the blades clean and lubricated so that you can enjoy its services efficiently. These specialist maintenance teams use more advanced tools and equipment in order to check for any signs of wear or damage. This meant as if you discover that a blade has bad state, then can be either fixed or changed it with the new.EVENTS AND PROMOTIONS Want More Buzz aldrin? And we assist you in.... Keeping those blades sharp so that wherever and whenever someone travels on an airplane, they do it safely and with reliability.

We follow jet engine blades for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.

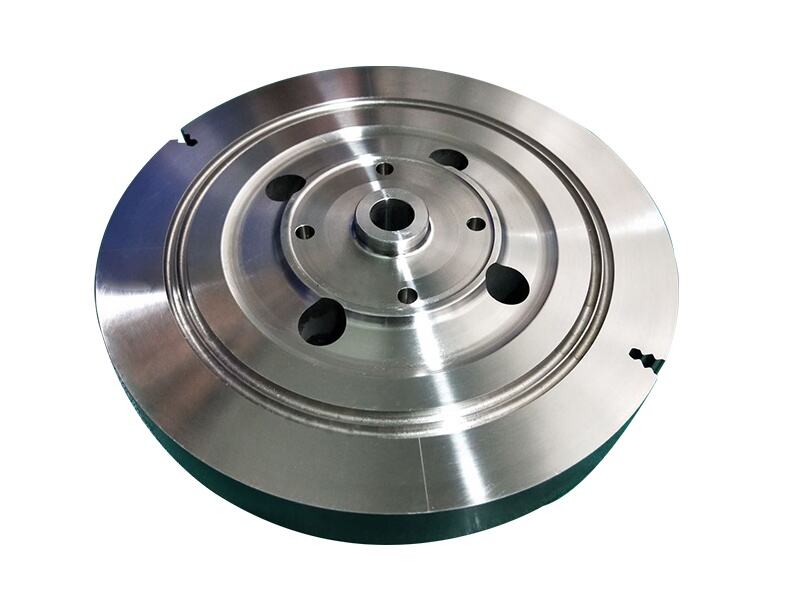

We are able to create turbine components with high accuracy and consistency using CNC casting, machining and forging processes. Casting allows us create parts with jet engine blades, strong and durability. Forging offers parts more durable and superior mechanical property. CNC machining, on the contrary is extremely precise and consistency for each part. This eliminates mistakes and poor quality products. Our experienced technical team is continuously researching technological advances and process optimizations in order to keep our products at the leading edge of industry technology. We're committed to meeting the demands of our customers for high-performance turbine components by the continuous advancement of technology.

Our company offers custom-designed services and can make jet engine blades in an array of high-temperature alloys in accordance with customer specifications. Whether it is a specific dimension, shape or requirements for performance, we can accomplish it by using our flexible production process and cutting-edge process technology. We collaborate closely with our customers to comprehend their needs as well as the various scenarios they might encounter and then offer them expert assistance and suggestions. Our diverse selection of materials processing capabilities, processing capabilities as well as specific requirements to the application allow us satisfy the specific needs of various industries and application. With customized services, we help our customers optimize the performance of their products and reduce costs, and improve market competitiveness.

Our customer support is comprehensive and includesjet engine blades, technical support, and after-sales services to ensure that our customers get the best experience possible. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support starting with the selection of products to installation and commissioning. This ensures that our clients are able to use our products without any issues. We have a well-developed after-sales process that allows us to swiftly respond to issues and needs of customers, and to provide effective and prompt solutions. We are determined to develop long-term relationships with our clients and gain their trust and respect by offering high-quality services.