Many of the things which require power, from planes flying high in the sky to factories that supply electricity for our homes are powered by gas turbine engines. Similarly, these engine function by drawing air from an opening in front of the engine. The air then goes into a component called an compressor. The compressor squeezes the air, which makes it quite hot. This air gets heated before entering the second section called as Combustor. In turn, hot air in which more fuel is added and burned creating even hotter air. Afterwards the hot air and exhaust gases pass through a turbine. The turbine is the section of the engine where power is made, and this power turns either an airplane's engines or the generator in a power plant.

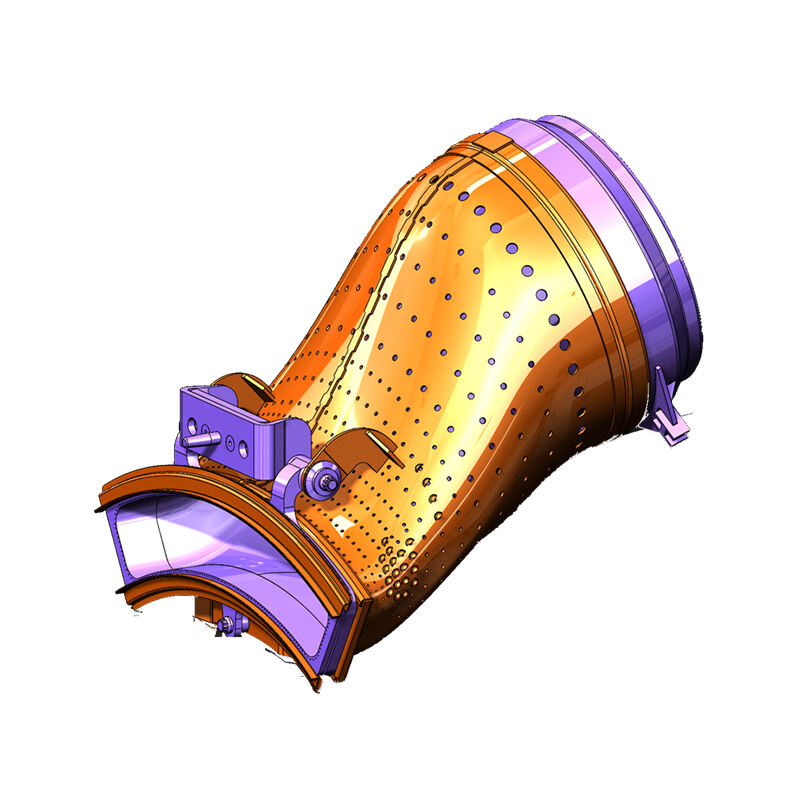

So, continuing that discussion, lets see how the nozzle guide vanes help. These vanes are very important to direct the exhaust gases in a specific direction through the turbine. For the engine to produce its maximum power, it needs airflow in that direction. Nozzle guide vanes ensure that the gases go through in a stable way which also helped to improve on what was done.

Nozzle guide vanes helps a lot by managing the flow of exhaust gases through the turbine. This way, they contribute to the best efficiency of engine. If that engine operates efficiently, it means a less thirsty mill - which is critical. The other advantage of this is that the engine also can last longer, which benefits anyone who depends on it.

Okay, so what are nozzle guide vanes made of? The construction of the vanes The material used for these vanes are made mostly with a tough type of metal that can withstand both high temperatures and pressures. The materials used are hand-picked to withstand the test of time and also be temperature resistant. Further to this, the nozzles guide vanes are also designed with very specific profiles and associated angles. They are designed with the optimal performance of an engine a priority to make it perform as efficiently as possible.

As the exhaust gases flows through, Nozzle guide vanes arc able to position them most efficiently for power production. They can be seen as the sort of nozzle on a garden hose. When you squeeze the nozzle, it aims the water flow and allows them to jet out in a manner. Similarly, nozzle guide vanes direct the flow of gas that has passed through an engine.

That is how important carefully shaping air with nozzle guide vanes are in the context of gas turbine engines. These are core ingredients that aid in the seamless operation and efficient performance of the engine. Without these blades, your engine would not be able to create the amount of power it should or operate as smoothly.

Nozzle guide vanes not only help in increasing engine performance, but also used for pollution control from gas turbine engines. By increasing the engine efficiency they can assist in reducing harmful emissions such as greenhouse gases and other noxious pollutants generated during operation. Which goes a long way in protecting the environment and the atmosphere.

Our company has the ability to create highly precise and reliable turbine parts through casting nozzle guide vanes function, and CNC machining processes. Casting allows us create components with complex designs, strong and long-lasting. Forging provides parts with a better mechanical quality and longer durability. CNC machining, on the contrary offers high precision and consistency for every component. This reduces errors and inferior products. Our technical staff is constantly developing technological advancements and process improvements to ensure our products are at the forefront of industry technology. We're committed to meeting our customers' demands for high-performance turbine components by continual technological advancement.

Our complete customer service package includes pre-sales consultation technical support and after-sales assistance to ensure our customers have the best possible experience When it comes to the pre-sales phase our experienced team will understand the customer's needs in detail and provide the most suitable suggestions and solutions In terms of technical support we offer full guidance from product selection until installation and commissioning to ensure that our customers use our products efficiently When it comes to after-sales service we have developed an nozzle guide vanes function service system that can respond swiftly to customer issues as well as needs and provide quick and effective solutions We want to create long-lasting relationships with our customers and gain their trust and appreciation by offering high-quality services

Our company is committed to strict quality control standards to guarantee the best performance and reliability of every component Every step of the production process is controlled for quality starting from the purchase of raw materials all the way to the final test of the product We also carry out regular quality audits as well as adjustments to ensure constant improvements in product quality Our goal is to win the trust and continue to work with of our clients by offering top quality products and to become an nozzle guide vanes function

Our company offers customized services, and can produce turbine components from an array of nozzle guide vanes function metals to meet the needs of customers. Our flexible production flow, advanced process technology, and our capacity to meet particular requirements, like size shape, performance, or shape can allow us to meet any requirement. We work closely with our clients to comprehend their needs specific to them and the application scenarios and provide professional advice and solutions. Our diverse selection of materials, processing capabilities and application-specific requirements allow us to meet the needs of a variety of industries and. With customized services, we help our customers optimize product performance and cost as well as increase market competitiveness.