Power plants need to have some subassemblies like the Turbine Transition Piece as they form a very important part of power generation. They are integral as they connect the gas turbine, which spins at high speeds, to the generator, which generates electric energy. It's what can transform the quick whirl into the electricity we all utilize safely at home, which is why this performance is so crucial. In addition, the transition piece regulates the flow of gases throughout the system and maintains the proper pressure inside the turbine. This enables smooth and efficient operation of the power plant.

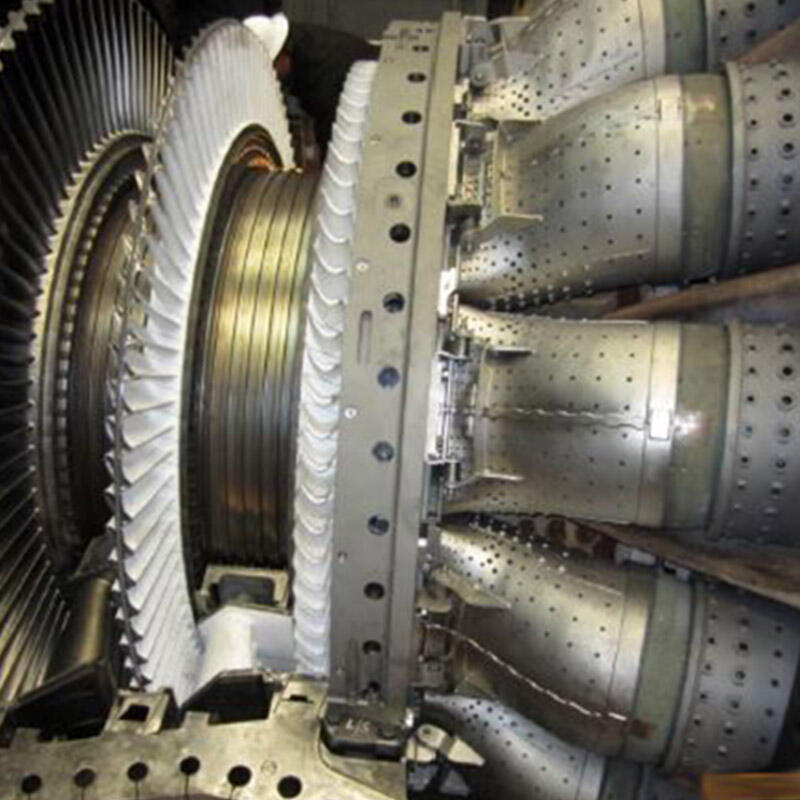

There are several components that make up the second stage turbine blade, and each of these components serving its own purpose. One critical component is the turbine coupling, the connector between the gas turbine and the generator. This link is essential as it transmits the energy from the turbine to the generator. This is where the turbine rotor comes in -- it's responsible for converting the mechanical energy transfer into electrical energy. The transition duct is the biggest section of the transition piece. Its job is to direct the hot gases out of the turbine and into the generator, also ensuring that the pressure and temperature are precisely normal. All of these components work together to generate the electricity we depend on.

And with that, allow me to introduce some new turbine transition piece technology. These advancements have revolutionized power generation. These developments are primarily based on more robust and durable materials, which can withstand extremely high temperatures and pressures. This allows for the components to endure longer and perform effectively in challenging environments. New manufacturing techniques now permit the more accurate construction and assembly of the parts as well. This ensures that it all fits in the right way. Thank to these new technologies power plants will not only get more productive but also cut down their operational costs, and that is good for all.

Good maintenance of turbine transition pieces is crucial in ensuring proper operation and longevity. Regular maintenance prevents issues based on costly repairs. These components of the heating system, like any other, need care and maintenance, and here are some necessary tips to keep them in shape: The first thing is to check the transition duct regularly for any dirt build up, and clean it up. This aids in maintaining a smooth airflow. Second, timely replacement of worn-out components prevent further damage. Thirdly, performing regular performance testing can help uncover potential problems early so they do not escalate to problems. Finally, it is important to keep the moving parts lubricated. This reduces the likelihood of having to deal with costly repairs thanks to effective lubrication and wear prevention.

This is very encouraging for how turbine transition pieces technology will develop going forward. Scientists and engineers are always coming up with new concepts for optimizing power generation further. Among the many interesting trends emerging in the industry is the use of advanced materials, such as ceramic composites and nanomaterials, which can give more efficient protection. Architects are also developing more efficient cooling techniques to better manage the heat. Adding a layer of automation and control systems, that can ensure power plants run in a smooth and safe manner. Cleaner energy production is vital for protecting our environment, and these trends will help toward that direction.

We follow turbine transition piece for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.

Our company offers a variety of custom-designed services and is able to manufacture turbine parts from various high-temperature alloys to meet the requirements of our customers. Our turbine transition piece along with our advanced process technology and our capability to meet specific requirements, such as size shape, performance, or shape can allow us to meet every need. We work closely with our customers to understand their specific needs and application situations and offer expert technical guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements to the application allow us meet the requirements of various industries and application. With our customized services, we assist our customers in optimizing their the performance of their products and reduce costs, and improve market competitiveness.

Our customer support is turbine transition piece and includes technical assistance, pre-sales advice and after-sales assistance to ensure our customers have the best possible experience. Our experienced team will review the needs of customers and offer the most effective solution and recommendations for the product. We provide technical support starting with the selection of products to installation and commissioning. This guarantees that our clients are able to enjoy our products without problems. We have a well-developed after-sales service that allows us to react quickly to customer requests and problems and provide quick and timely solutions. We strive to establish long-term relationships with our customers and earn their trust and respect by providing quality service.

Our company has the ability to create highly precise and reliable turbine parts through casting turbine transition piece, and CNC machining processes. Casting allows us create components with complex designs, strong and long-lasting. Forging provides parts with a better mechanical quality and longer durability. CNC machining, on the contrary offers high precision and consistency for every component. This reduces errors and inferior products. Our technical staff is constantly developing technological advancements and process improvements to ensure our products are at the forefront of industry technology. We're committed to meeting our customers' demands for high-performance turbine components by continual technological advancement.