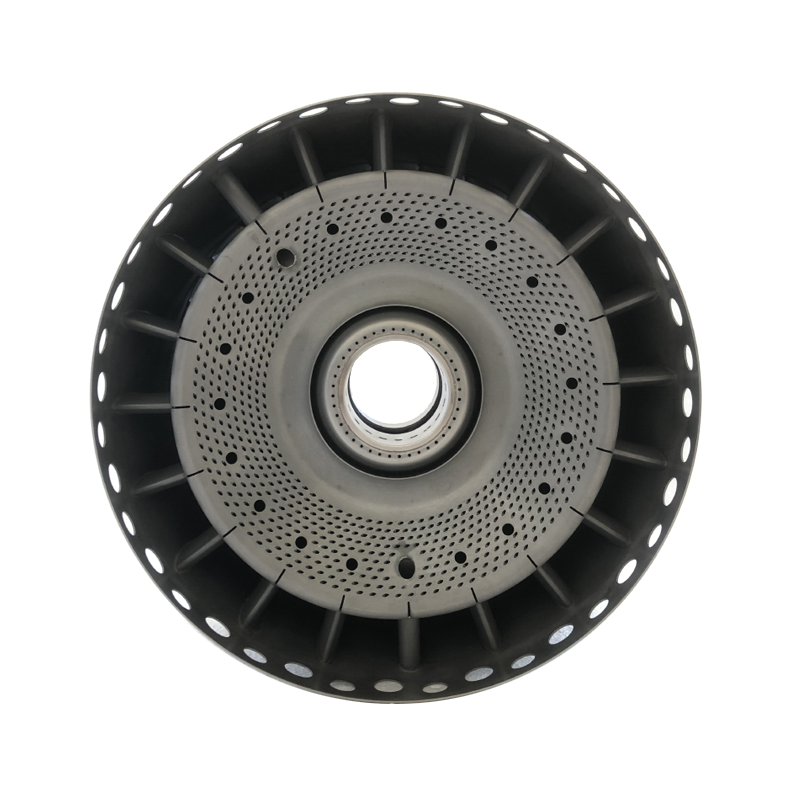

टर्बाइन वे स्टील की संरचनाएँ हैं जो इस पृथ्वी की सतह से काफी दूर होती हैं और उन्हें भाप, पानी या गैस द्वारा चलाया जाता है ताकि ऊर्जा उत्पन्न हो सके, और यही वह बात थी जिसे मैं खुदसे याद रखता था जब हमें उनके बारे में पढ़ाया जाता था। स्टेटर और रोटर वे दो महत्वपूर्ण तत्व हैं जो टर्बाइन में मौजूद हैं। रोटर चलता है, घूमता है या फिर घूमता है। स्टेटर नहीं चलता। पहले थोड़ा यह समझें कि ये दोनों हिस्से कैसे मिलकर कुशल ऊर्जा प्रदान करते हैं!

टर्बाइन, जब अपने आप पर बल लगाती है, तो रोटर को चलना शुरू करती है और ऊर्जा उत्पादन शुरू हो जाता है। हालांकि, यह लगभग एक नृत्य की तरह है - (रोटर अकेले ऐसा नहीं कर सकता!) यह स्टेटर के समर्थन पर निर्भर करता है। स्टेटर पर छोटे-छोटे ब्लेड लगे होते हैं जो भाप या गैस के प्रवाह को रोटर ब्लेड पर पुनः दिशित करते हैं, जो महत्वपूर्ण है। इस तरह से रोटर ब्लेड घूमते हैं और अधिक ऊर्जा उत्पन्न करने के लिए काम करते हैं। स्टेटर और रोटर एक जोड़ी की तरह काम करते हैं जो ट्रांसफार्मर को एकजुट रूप से संचालित करते हैं और ऊर्जा को दक्षता से उत्पन्न करते हैं।

टर्बाइन के अंदर स्टेटर और रोटर अत्यधिक महत्वपूर्ण भाग हैं। स्टेटर आने वाली भाप, गैस या पानी को सही तरीके से टर्बाइन के माध्यम से निर्देशित करता है। इसी समय रोटर भाप, पानी या गैस से प्राप्त ऊर्जा का उपयोग करके टर्बाइन को घूमने के लिए ऊर्जा प्रदान करता है। स्टेटर और रोटर को एक साथ काम करना पड़ता है, अन्यथा टर्बाइन से कोई ऊर्जा नहीं उत्पन्न की जा सकती!

स्टेटर और रोटर की आवश्यकता ऊर्जा उत्पादन के क्षेत्र में भी महत्वपूर्ण है। ये टर्बाइन के भाग हैं, जैसे वायु टर्बाइन और जलविद्युत टर्बाइन। ऐसी वायु टर्बाइन प्रत्यास्थ ऊर्जा के निर्माण में महत्वपूर्ण हैं, जो अपेक्षातः कम प्रभाव वाली या पुनर्जीवनी ऊर्जा के रूप में होती है। स्टेटर और रोटर के बिना हमें प्रत्यास्थ ऊर्जा उत्पन्न करने और हमारे ग्रह को बचाने की कई कम संभावनाएँ होंगी।

टर्बाइन में स्टेटर और रोटर के बीच अंतर्क्रिया डायनेमिक्स का विस्तृत अध्ययन उनकी ऊर्जा उत्पादन के लिए इन टर्बाइनों में अपरिहार्य भूमिका को स्पष्ट करता है। सहयोग से, वे घरों, स्वास्थ्य सेवा सुविधाओं/क्लिनिकों - विद्यालयों और यहां तक कि शहरों के लिए बिजली प्रदान करते हैं। स्टेटर का एक और बहुत महत्वपूर्ण कार्य है; यह भाप या गैस को रोटर ब्लेड्स की ओर मार्गदर्शित करता है, जहाँ यह ऊर्जा घूमने में जुड़ती है और उपयोगी यांत्रिक/विद्युत आउटपुट में परिवर्तित हो जाती है। यह चक्र तब तक जारी रहता है जब तक कि आवश्यक ऊर्जा उत्पन्न नहीं हो जाती। स्टेटर्स और रोटर्स के बीच अंतर्क्रिया इस संबंध की महत्व को बताती है कि टर्बाइनों के भीतर ऊर्जा कैसे उत्पन्न होती है।

सरल शब्दों में, स्टेटर्स और रोटर्स एक टर्बाइन के विशाल प्रणाली में छोटे हिस्से हैं, लेकिन ये बहुत शक्तिशाली हैं। हमारी टर्बाइन से ऊर्जा उत्पन्न करने की क्षमता बहुत हद तक इन हिस्सों पर निर्भर करती है, क्योंकि बिना इनके वे व्यावहारिक रूप से अवास्तविक हो जाएंगे, और हम नवीकरणीय ऊर्जा का उपयोग आगे नहीं कर पाएंगे। तो जब आप 'टर्बाइन' शब्द को सुनें, तो रुककर सोचें कि ये दोनों घटक कैसे मिलकर ऊर्जा बनाते हैं।

हमारी कंपनी टर्बाइन के भागों का उत्पादन कर सकती है, जो धातु पिसाई, जोर देने की प्रक्रिया (forging) और CNC मशीनिंग प्रक्रियाओं से अत्यधिक सटीक और संगत होते हैं। धातु पिसाई प्रक्रिया हमें जटिल आकार वाले और मजबूत डूरदार भागों का उत्पादन करने की अनुमति देती है, जबकि जोर देने की प्रक्रिया टर्बाइन में स्टेटर और रोटर को बेहतर बनाती है और इसकी जीवनकाल बढ़ाती है। उल्टे, CNC मशीनिंग प्रौद्योगिकी प्रत्येक भाग की संगति और उच्च गुणवत्ता की गारंटी देती है, जो उत्पादन में त्रुटियों की संभावना को कम करती है और खराब उत्पादों को रोकती है। हमारे पास एक अत्यधिक कुशल तकनीकी टीम है, जो निरंतर तकनीकी नवाचार और प्रक्रिया सुधार करती है ताकि हमारे उत्पाद तकनीकी रूप से उद्योग में अग्रणी बने रहें। हम अपने ग्राहकों की आवश्यकताओं को पूरा करने के लिए प्रतिबद्ध हैं, जो उच्च-प्रदर्शन वाले घटकों के लिए निरंतर तकनीकी विकास करते हैं।

हमारी कंपनी टर्बाइन में स्टेटर और रोटर प्रदान करती है तथा ग्राहकों की आवश्यकताओं के अनुसार कई विभिन्न उच्च तापमान प्रतिरोधी मिश्र धातुओं में टर्बाइन घटकों का निर्माण कर सकती है। आकार, आकृति या प्रदर्शन आवश्यकता कुछ भी हो, हम अपनी लचीली उत्पादन प्रक्रियाओं और उन्नत प्रक्रियाओं का उपयोग करके उन्हें पूरा करने में सक्षम हैं। हम अपने ग्राहकों के साथ निकट सहयोग करते हैं ताकि उनकी आवश्यकताओं और अनुप्रयोग परिदृश्यों को समझा जा सके, और फिर उन्हें पेशेवर सहायता एवं सुझाव प्रदान किए जा सकें। हमारे पास विभिन्न क्षेत्रों और अनुप्रयोगों की विशिष्ट आवश्यकताओं को पूरा करने के लिए प्रसंस्करण और सामग्रियों की विस्तृत श्रृंखला उपलब्ध है। हम अपने ग्राहकों को उनकी बाज़ार प्रतिस्पर्धात्मकता में सुधार करने में सहायता करते हैं, जिसके लिए हम ऐसी अनुकूलित सेवाएँ प्रदान करते हैं जो प्रदर्शन में सुधार करती हैं और लागत को कम करती हैं।

हम प्रत्येक घटक की विश्वसनीयता और प्रदर्शन सुनिश्चित करने के लिए गुणवत्ता नियंत्रण के सबसे कठोर मानकों का पालन करते हैं। गुणवत्ता नियंत्रण को उत्पादन की पूरी प्रक्रिया में, कच्चे माल की खरीद से लेकर टरबाइन में स्टेटर और रोटर के परीक्षण तक, आयोजित किया जाता है। यह सुनिश्चित करने के लिए कि हमारे उत्पादों की गुणवत्ता लगातार बेहतर होती रहे, हम नियमित ऑडिट और सुधार कार्य करते हैं। हमारा उद्देश्य उच्चतम मानक के गुणवत्तापूर्ण उत्पाद प्रदान करके अपने ग्राहकों का विश्वास जीतना और उनके साथ निरंतर सहयोग करना है, ताकि हम इस उद्योग में एक अग्रणी संस्था बन सकें।

हमारी व्यापक ग्राहक सेवा में पूर्व-विक्रय परामर्श, तकनीकी सहायता और उत्तर-विक्रय सेवाएँ शामिल हैं, जिससे सुनिश्चित होता है कि ग्राहक सबसे अधिक संतोषजनक अनुभव का आनंद ले सकें। हमारी विशेषज्ञ टीम ग्राहकों की आवश्यकताओं का आकलन करेगी और उचित उत्पाद सुझाव तथा समाधान प्रदान करेगी। हम उत्पादों के चयन से लेकर स्थापना और सुरक्षित संचालन (कमीशनिंग) तक तकनीकी सहायता प्रदान करते हैं। इससे यह सुनिश्चित होता है कि हमारे ग्राहक हमारे उत्पादों का बिना किसी समस्या के आनंद ले सकें। उत्तर-विक्रय सहायता के लिए, हमने एक कुशल सेवा प्रणाली विकसित की है जो ग्राहकों की समस्याओं और आवश्यकताओं के प्रति त्वरित प्रतिक्रिया कर सकती है, साथ ही टरबाइन में स्टेटर और रोटर भी प्रदान कर सकती है तथा कुशल समाधान प्रदान कर सकती है। हमारा लक्ष्य उत्कृष्ट ग्राहक सेवा प्रदान करके दीर्घकालिक संबंध स्थापित करना, ग्राहकों का विश्वास अर्जित करना और उनकी संतुष्टि सुनिश्चित करना है।